jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

Please help, advise. Adler 5-6 , plate, presser, feed dog.

jimi replied to Szymon's topic in Leather Sewing Machines

Yeah, no problem, All the best. -

Please help, advise. Adler 5-6 , plate, presser, feed dog.

jimi replied to Szymon's topic in Leather Sewing Machines

Yes the GA5-1 parts should fit, i have a plate here and measures almost exactly the same so i think it would work and they cant get any cheaper for a whole setup like that. The one you have on it is a copy of the singer 45k type they used for sewing shoe soles, and it looks like it might be a fixer upper foot?? -

Please help, advise. Adler 5-6 , plate, presser, feed dog.

jimi replied to Szymon's topic in Leather Sewing Machines

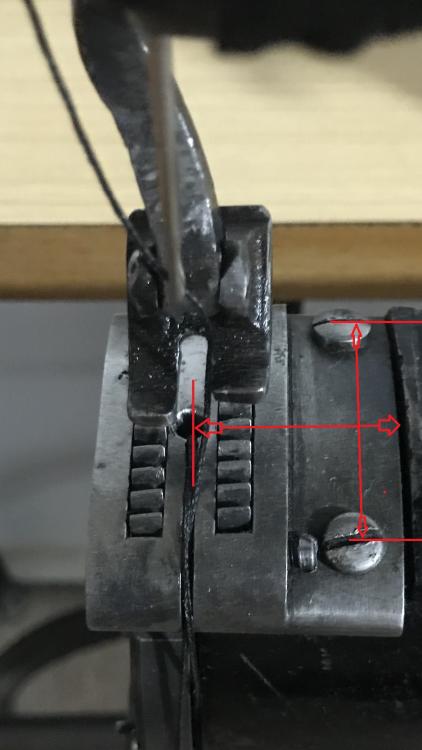

Could you measure the plate according to the picture? I don´t think you will find a flat plate for that machine?? It would have to be curved, and even curved ones are hard to find. -

Thanks gl2t1a, Is that a 45k56?? 1910-20??

- 11 replies

-

Nice machine there.

- 11 replies

-

Sorry, the take up lever arm is threaded after the check spring, my mistake. You need to go around the pulley 1 and 1/2 times. in the manual it tells you to go around the tension wheel (3).

-

Thanks Chris. Nice info there.

-

Maybe i am calling them by the wrong name?? The curved needles used on the Goodyear Rapid E Type sole stitchers?? Not sure if Landis use the same needle?? seems hard to find prices for them on the net.

-

Hi there, was wondering if anyone knew the price of the Goodyear RapidE Needles??

-

Your welcome Mike. Here is a link to some videos a guy put up about a 45k89 which is the cylinder arm version of your machine. There are 5 videos i think?

-

Hi Mike, Well done on your purchase. I think your machine will last another 100yrs. First thing i would do would be to get the parts manual and look and see what the parts are called and what they do. http://dixiesewingmachine.tzo.com/MANUALS/SINGERPARTS2/45K58.pdf And here is the link to the manual that will show you how to thread it properly. It also has more stuff on the 45k class machines. If it gets out of timing then it is set by moving your needle bar up or down. You can take the Shuttle Race Spring and Screw, Shuttle Race cap and Shuttle out to clean no worries. They call this a kick foot in the UK and the spring part on top is called the presser Bar Gripping Bracket. That will most likely have to do with the action of your foot when Climbing (Singer called it Vibrating And Climbing Presser). The pressure for you foot is done with the flat bar at the back, Similar to that of the 29k. When you change the stitch length there is a small screw and nut with a small arm behind the foot assembly which i think regulates the foot stitch length to equal your feed dog. Someone has added a bracket on your face plate for the thread going through ?? After the Take Up Lever Arm, And your thread is going through your spring instead of going around the Tension Pulley? ( 1 and 1/2 times around) Hope this helps, Jimi.

-

Altering flat bed accessory for cylinder arm

jimi replied to Ceejay's topic in Leather Sewing Machines

Hi, I would talk with the seller before you cut up the table and get a refund?? It looks like it could be for another type of machine and not yours. -

Singer 132K SV 11 -> a 132K6 variant?

jimi replied to Constabulary's topic in Leather Sewing Machines

Great job Folker, That turned out really well, I think we all have machine envy now! When are you opening up the Singer Museum?? -

Hi, Did you find the parts you were looking for?? Who is the maker of the skiver machine??

-

Suspended edge guide doesn’t fit right? What to do?

jimi replied to myjtp's topic in Leather Sewing Machines

The Kwokhing swing down guide came with a small extended piece probably for this situation. Like Folker said, if you get a longer piece of steel same as the one you have the guide fixed to then you can fix your guide further out to the right. http://www.kwokhing.com/pfaff/ -

Hi Mark, here is a link where you can download a manual for the singer 45k. your machine looks like a Adler 5-6 which are copy´s of the singer 45k so threading is the same. you should oil your machine before using but if it is moving ok the you wont do any harm to it. in the manual you can see where to oil and on the bottom arm look for all moving parts and holes. looks like your thread is a little too thin, 3 cord, T210 or Tkt15 bonded nylon and a nº 23 needle should get you sewing if there is no problems with the machine? did the previous owner have it sewing??

-

Nice find, now you have some spares if the good one breaks down. Like Folker said, did you get any pictures?

-

Le Cuir. Compositions Decoratives Pattern book

jimi replied to DebHop's topic in Patterns and Templates

Thanks for sharing Tom. jimi.- 18 replies

-

- art nouveau

- carving

-

(and 3 more)

Tagged with:

-

Interesting old YouTube Video - Saddlers in Ireland

jimi replied to jcuk's topic in Saddle & Tack Maker Gallery

Very interesting video jcuk, thanks for sharing. -

Hi Don, I have been doing NDT or as you call it crack detection work for the past few years and to detect a little better the cracks you normally use a white contrast paint before applying the black particles mixed with kerosene , this way they are free to move around to the crack. you normally do it without contrast paint when it is hot, then you use what they call a pear to sprinkle the powder on and this is red to contrast with the dark metal background (the particles are very fine). Before they used liquid penetrants like you see today, they would apply oil, let it penetrate a while then clean the top surface only lightly to get rid of the oil on the surface and then apply chalk powder. if any dark areas appeared that would be a sign of the chalk absorbing the oil from a crack. If you are going to be doing this often i would look for a can of dye penetrant, 1 of cleaner and 1 of developer this way you will find very fine cracks as long as you execute it properly. If one day you do it, let me know. If you keep doing your magnet method, move them around as the cracks could be orientated at a different angle to the magnetic field you are applying (normally 90º to the first position). Hope this helps, Regards jimi.

-

Help with replacing tension disk - singer 29k8

jimi replied to stor's topic in Leather Sewing Machines

Sorry guys i still do it the Noob way hehehe. oh forgot to say Stor, if you do it the noob way you will need to take the leaf spring at the back off also. -

Hello DanishMan, what make is it? Fortschritt,Fortuna,Fav?? maybe you could show a picture of the machine? I don´t know about bell knifes and grind stones but i have a belt from the last owner and he said it was new, it has cracked and come apart. the rubber has perished. if i compare this to one i bought from Fortuna, the one from Fortuna feels and looks better. The feed stones from china will not fit the fortuna (they might fit other makes) as they are to big in diameter. you would have to grind a small corner off or get a similar cheap part from china for the feed stone. the metal feed roller i bought came out of shape.(they refunded and said i could keep the wheel) saying that i bought a emery feed stone from seick and that also came out of shape. (was changed and 2nd wheel was better) I recently bought one from Ebay which was boxed new from Fortuna and it was perfect first time. I am not a big fan of buying original parts at high prices but some times it is worth it. the feed wheel on ebay was 30 pounds and if you buy this from Fortuna it would cost around 90+vat+postage. What i done was asked for prices of the parts from both places and compared the prices. some are almost the same and if i can remember others are even more expensive from seick. I think both sell the bell knife around the same price so in this case i bought it from Fortuna, I think it was about 40-50 euros. hope this helps DanishMan.

-

Help with replacing tension disk - singer 29k8

jimi replied to stor's topic in Leather Sewing Machines

Hi Stor, I think if i recall correctly you unscrew the foot and take off the stitch length regulator clamp and then take off the tension screw,spring and cup and it should lift up enough to let the disks out. -

I have a manual for the Fortuna skiver if you are interested.

- 11 replies

-

- skiving machine

- skiver

-

(and 1 more)

Tagged with:

-

Good luck with the Fortuna GeorgiaK. If they have a spare left cover would you let me know?

- 11 replies

-

- skiving machine

- skiver

-

(and 1 more)

Tagged with: