jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

I was asking Casemaker, the guy with the protos machine, if it was broken=Knackered.

-

Id love one of them....very cool machines. Is yours knackered then casemaker?? Sieck would probably have parts for them but maybe not too willing to sell them as they use them for refurbishing other machines. Here is the machine in action if anyone was wondering how it stitches and what it can do??....https://www.instagram.com/nystromsthlm/

-

Sewing machine - transition from thin to thick, getting hung up

jimi replied to Dave3006's topic in How Do I Do That?

Maybe it would be a good ides to skive that transition area?? -

Hi, Try this..http://dixiesewingmachine.tzo.com/MANUALS/SINGERSERVICE/31K-Inst.pdf http://dixiesewingmachine.tzo.com/MANUALS/SINGERPARTS1/31-15.pdf

- 2 replies

-

- 31-15

- thread size

-

(and 1 more)

Tagged with:

-

If you do not have a connection at the bottom of the arm for the light, then probably that pin you are talking about is for the wires of the lamp. on the Fortuna there is a din pin at the bottom of the arm for plugging in the lamp. The lamp is the same one that Matts has on his Fortuna splitter machine so i think yours would be similar, goosenecked.

-

Great stuff Matt, Its looking good...

-

Thanks for sharing Danne,

- 13 replies

-

- fenice

- edge paint

-

(and 1 more)

Tagged with:

-

Nice restoration Katit, keep the pictures coming...The bolt on the arm is where a lamp would go.

-

This looks like it is the same machine?? https://es.aliexpress.com/store/product/110V-220V-TK-801-Leather-Skiving-Sewing-Machine-for-Edge-Scraping-Synthetic-Leather-Shoes-Plastic-Articles/2026034_32699404683.html?spm=a219c.search0104.3.1.1b881faexSgPNB&ws_ab_test=searchweb0_0,searchweb201602_6_10065_10068_10547_319_10891_317_10548_10696_10084_453_454_10083_10618_10307_10820_10821_10301_10303_537_536_10902_10059_10884_10887_321_322_10103,searchweb201603_61,ppcSwitch_0&algo_expid=595c59a0-1cf0-46b8-b138-b0656b4d143f-0&algo_pvid=595c59a0-1cf0-46b8-b138-b0656b4d143f&transAbTest=ae803_5

-

-

I think that cone of thread on the floor is for refilling the bobbins Al, you can see it in the first picture.

-

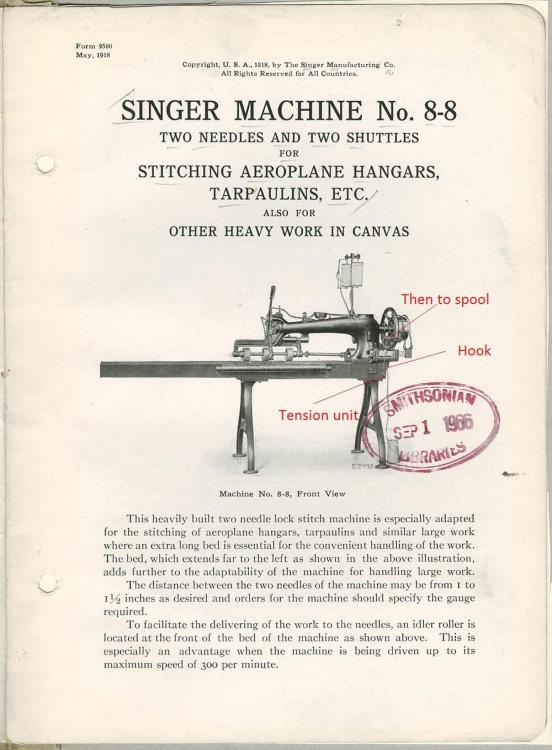

Hi Al, Hows things???What 45k were you looking for??? I used to use one of these machines for sewing sacks when i stayed in London. It was like one of those electric jig saws for wood.. same sort of size and when you finished the sack there was blades for cutting the thread, you just turned it into the blades. (not a very interesting job that one?? making muesli by the ton Was this the singer you were looking for Al???http://www.sil.si.edu/DigitalCollections/Trade-Literature/Sewing-Machines/NMAHTEX/0148/ this one is for Aeroplane Hangars....

-

Although the 105-64 is a nice med-heavy duty needle feed machine, i think you would be better off looking for an Adler 69 or Pfaff 335 type machine. I am sure there are other options from other makes for this class of machine also. I personally use a Pfaff 335 for wallets,purses etc.... On the other hand if you were planning on doing belts and heavy stuff which needs a bigger needle and thicker thread, then the 105 is a very good choice. hope this helps.

-

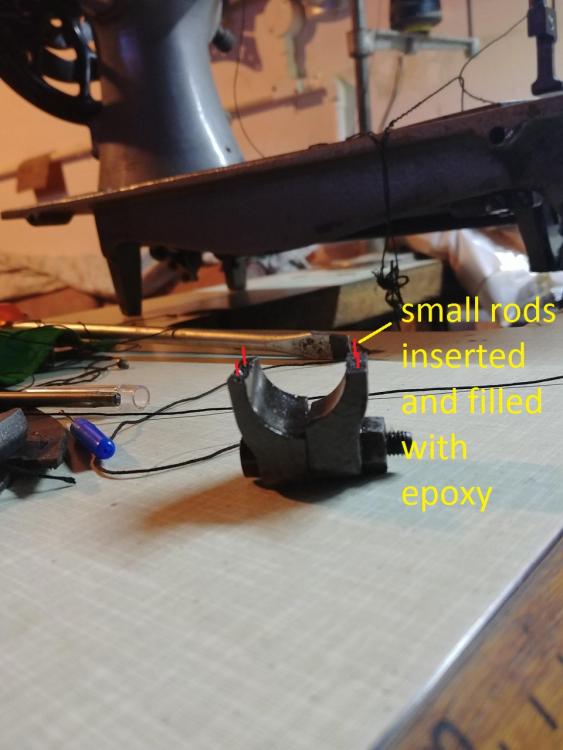

What size of needle and thread are you using?? Well at least it looks like a clean break. I would give it a try charlie, it worked well on mine and i had to pass a tap to make the thread on the epoxy side also. You would need to clean well the both parts where the break is, no oil and stuff. I would drill the holes slightly bigger than the rods to help line up the parts, then fill up the holes with epoxy, insert the rods and the join the parts together and let it set. If that does not work then look for a good welder. In the picture i put an example of 2 holes, if you can get 4 each side then better. If you do do it with epoxy then remember to tighten a very little amount.

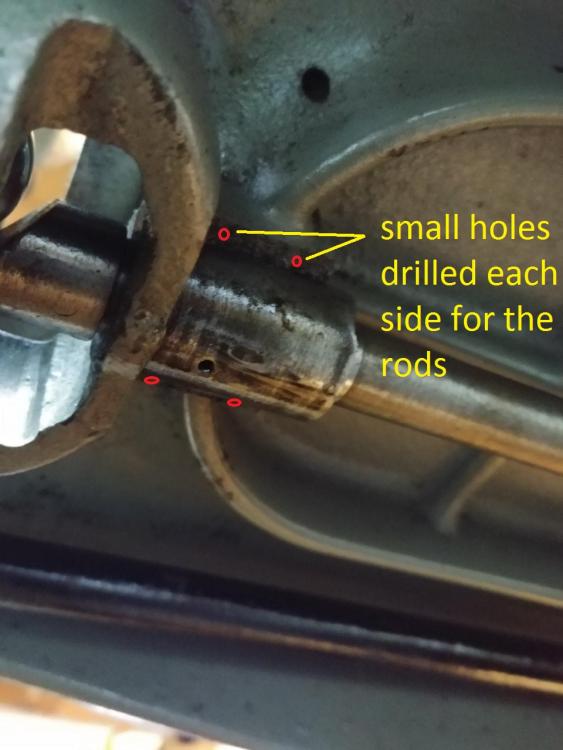

-

After that breakage is the bushing loose and turning?? or is it still fixed in its position?? if it is still fixed and not moving then could you send a picture of your thread path. If the shaft is not wobbling or the bushing not moving and everything is the same as before, then i would leave it. if not then... I am no expert and only suggesting what worked for me. What i would do would be to drill some small holes in the casting, put some small rods in and JB weld it. The epoxy sets hard as a brick. Normally i don´t think you would need to touch that bushing unless it was worn or something. The clamp would be to stop it from turning with the shaft i suppose. The other option is to pour the epoxy all over the bushing leaving the oil hole free and just fixing it so it can´t move. i personally would try the first option. Also in the pictures on the other thread it looks like you are sewing on some thin felt?? try a thick piece of leather if you have some around. I don´t think These machines are meant for sewing thin material.

-

What shaft are you referring to? the one underneath?? Here is a fix i done on a 45k92 i bought for selling, the back leg was missing and it broke right in the middle of the thread.

-

Is this stitching weakening the belt loop?

jimi replied to GeneH's topic in Leatherwork Conversation

I personally do not see the stitching being a problem? I don´t think you even need the rivets if you are stitching this by hand top and bottom? you did say it was for an axe?? If it was for bungee jumping then maybe better with the rivets as well -

Bonded nylon thread 8 oz spool uncoiling solution

jimi replied to kgg's topic in Hardware and Accessories

I think normally for this situation you would use a piece of mesh over the thread, the type they use to protect tubes and bars. -

Here is a 92 like the one you have charlie, and the foot it comes with. And here is the old dear that wobbles... And this is a common 45k21 cylinder version. They all thread up the same way. If you could send some pictures then we could try to find a solution. Jimi.

-

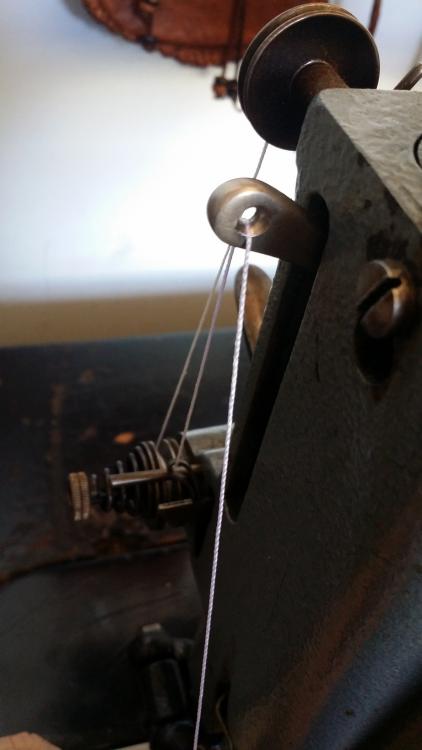

There should be a bit of resistance from the thread coming out of the shuttle. This machine is the same as your 45k92 Charlie with the exception it was called the 45kSV99 before it was called the 45k92. This model came with a foot not a roller. Ohppss! forgot to put the thread behind the wire on the needle clamp

-

Hey Charlie, don´t give up on the old dear yet, i think it will be something you might have not seen or overlooked?? I have an old singer 45k1 from 1895 with a wobbly needle bar and it has seen better days, it feels very worn and it was left to rust, but believe it or not it does not miss a stitch now the parts are on it.( it still has the wobbly needle bar on it!) If you take out your shuttle out, there should be a small screw for applying tension to your spring? if you have thin thread in the spool then you will not get any tension as these machines are made for sewing with thick thread. Maybe #207 bonded nylon would be a good place to start. There should be a little tension to the thread when you pull it from the shuttle, if not then tighten it more. If the screw is all the way in then it could be that your shuttle spring is worn, your shuttle case is worn or your thread is too thin?You can find in this post how to thread your machine properly and don´t forget to go around the pulley wheel 1 1/2 times after you come out of the top disks like it says in the manual. Like Rockoboy said, best idea is to send some pictures, that way someone could spot the problem from the pictures. Here are a couple of pictures of some of the 45k machines and the thread path.

-

Singer Industrial Sewing Machine Screws

jimi replied to shoepatcher's topic in Leather Sewing Machines

http://dixiesewingmachine.tzo.com/index.htm -

Singer Industrial Sewing Machine Screws

jimi replied to shoepatcher's topic in Leather Sewing Machines

Hi Glenn, is this the one you were looking for???https://www.singersewinginfo.co.uk/screw_threads/ -

That was an excellent restoration job, well done. Did you patch the hole up and sand it in to look the same??