jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

-

Binder plate going back on, remember if you are binding then great but if you change out feed dog and needle plate this will probably drive u nuts as it will move your hand if you rest it on it and the screws could mark a leather project, so if you can look for something else. I used a 4-5mm aluminium plate which i recessed out where the screw goes back and forward leaving the plate unmovable.Well you could make it out of plastic if you have a 3d printer or whatever?? I had a small piece of felt left over from the black 335, now i know where it goes??? it gets held on with a small screw on the inside of the head cavity on the left side and is probably oiled regularly as the base of the take up arm touches it every turn. It is almost in the position in the picture, there is a small window at the back outside left where the oil is applied.

-

That is a drop in part, no fuss and as you can see it is down to the plate. so the other bar was bent. needle plate screw missing For putting on the stitch length lever i think it was easier when in position 0. screw the outer part first then tighten in 0 position then put the spring in and tighten.

-

Ok so back in and on the arm again.... so do you see that??? when something tells you that something is not right... then it´s not right,right! The arm is raised above the front plate and there is no obstruction where it pivots at the back, also i know from the black 335 this is on top of that front plate. so i quickly put in the needle plate and feed dog and saw that it was pushing it down. Me thinks that someone tried to take it out with a screwdriver and forced it up?? It is difficult to slide out as you need to push down lightly under where that dirty screw was as this is mobile and moves up,down,front,back. this is easier to get out in the black 335, no pushing nuttin just straight out.. I did find one on Ebay yonks ago for ??? 10 euro! so it did come in handy. And yes another dirty hole!

-

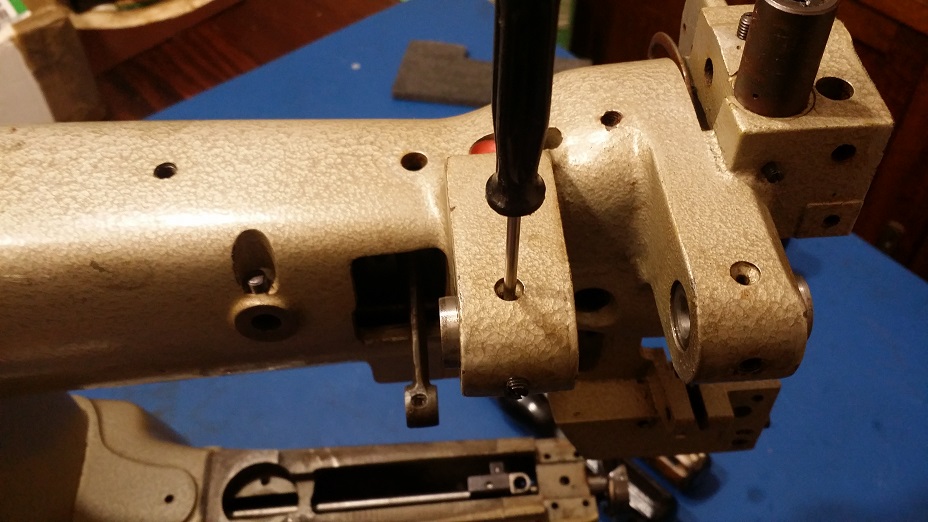

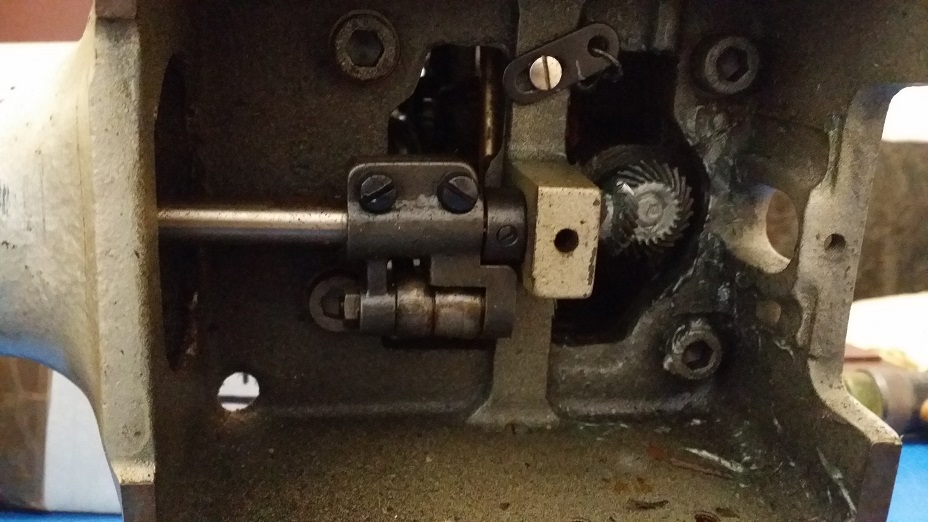

This screw is where your bar moves front to back for your feed dog motion and as you can see the screw has a oiling hole which later comes out the side, well you can see just how much dirt this thing eats!!

-

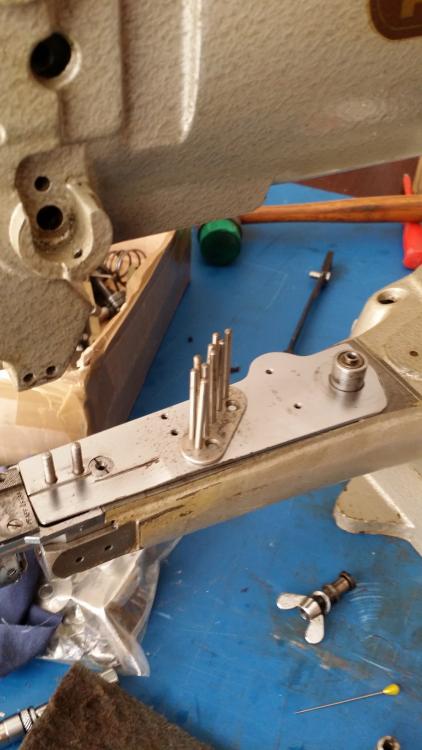

Here we have this front assembly plate where the needle plate fixes to and the finger positioner, that is the small plate on the front with the two small screws which will hold the basket in its place and stop it from spinning around. if this happens then you will hear your needle bang and you could do some damage especially if you have a heavy needle in it. One thing about the old black 335, this part has one fixing screw which screws from underneath and seems to be adjustable?? where as this finger is in a fixed position, no adjusting. Someone has put in a domed head screw??

-

Now the basket will not fall out we have to put the finger positioner on to hold it in the right place.

-

As you can see the basket needs cleaning before going back on again. Be careful, very small screws ahead!!

-

-

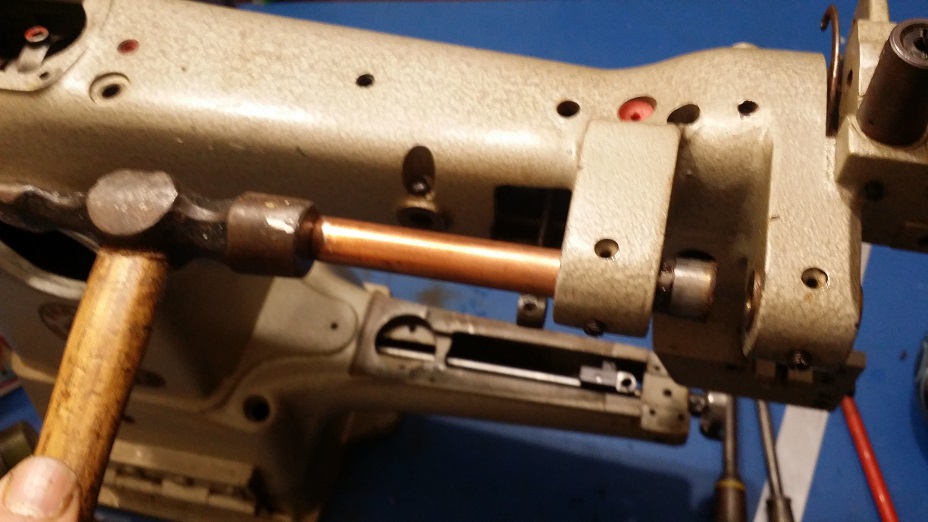

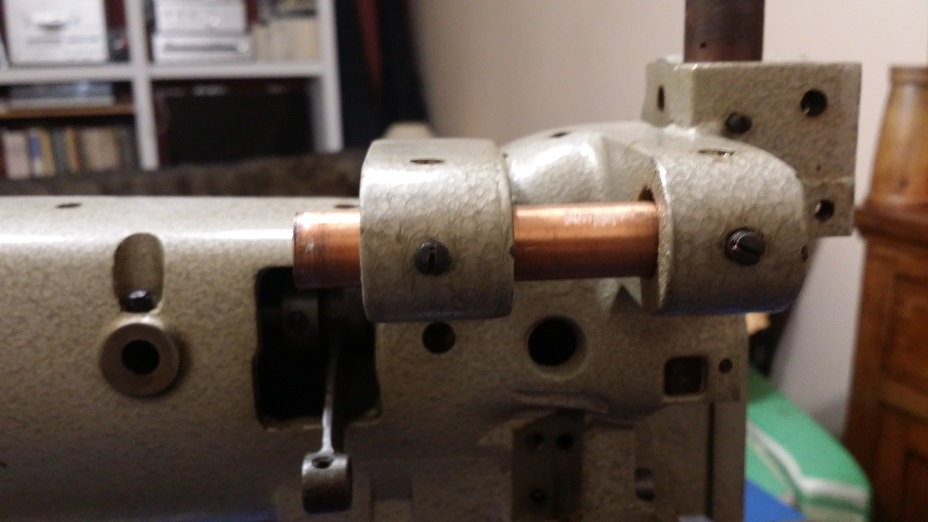

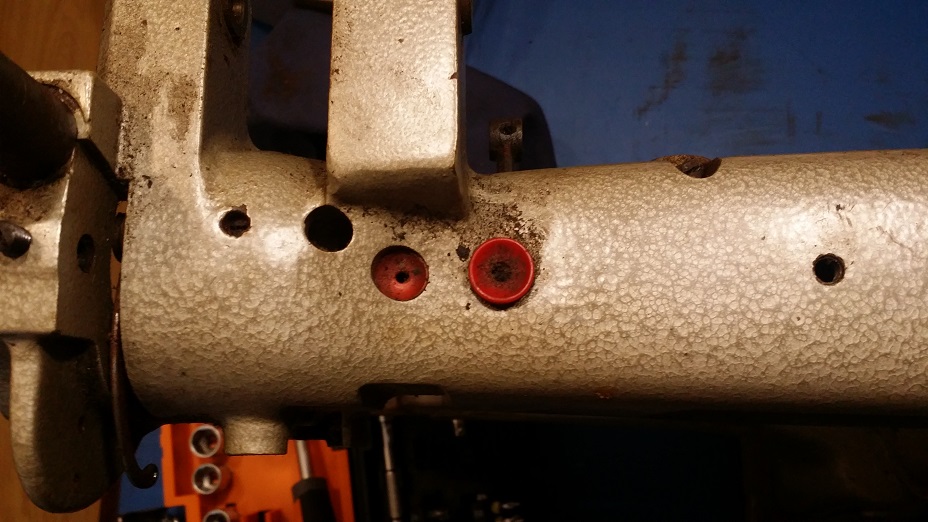

Just to make sure the holes are free from dirt and in line with the casting otherwise you wont be able to oil the shaft from here. Sorry, in the last pictures of the bushings you don´t see the holes but they also have holes in them to let pass the oil to the shaft through the bushing. In this picture the screwdriver is passing through the casting and the bushing. That is a piece of steel bar for tapping out the top bushing for cleaning the rust, not the foot bar! I think now that it has no rust and it is clean i will give it a couple of coats of lacquer to protect it again....

-

Is there a number hidden under the paint?? Natural soap and warm water.. Remember if you want to take out these bushings to unscrew the two grub screws first. I should have taken the right hand side bushing out first, as the left one was inside and not standing proud of the hole, this way the bushing would have fallen out in the middle. so i had to get both out the same side as the right hand one did not leave space enough for the other to drop out.Bahh no worries. They were not that dirty really?? I personally don´t like hammering old parts out of casting!! you know why?? That`s better. Oh, one thing to remember, the position of the bushings, you will see why later.

-

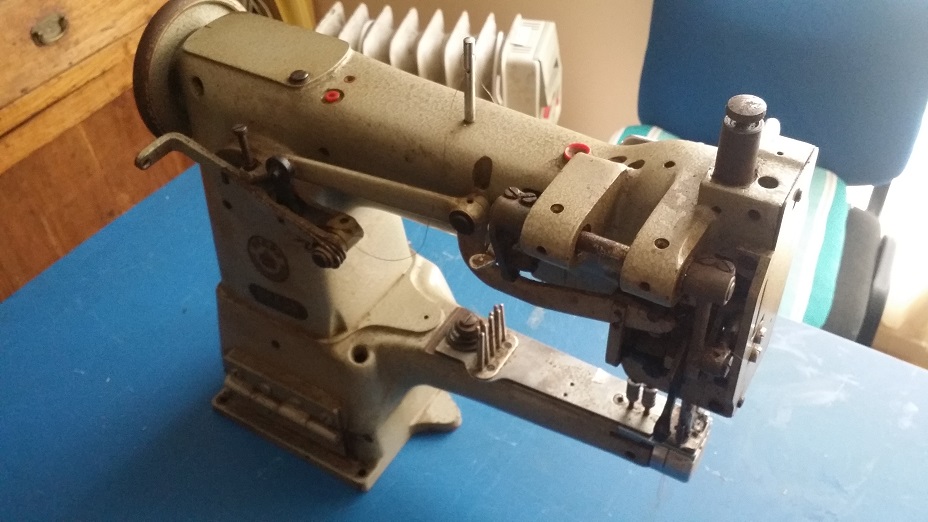

Ohhps! out of focus. just going from screw to screw and taking them out This part was not on the old black one, it is for the pin that goes through the head to open the tension disks. Once cleaned we can see the reverse order instead of taking the same pictures twice. So this is pretty much where i want to get to with this one also. no shafts coming out etc... because i think they don´t need to come out. Under here someone has put a silver like grease on the pinions and the small box for collecting the oil is missing, hence the two holes with no screws. so after putting oil down the tube from the front, this would go onto the pinions and any surplus fall in the box. So i think i will leave the grease on until i find a box ( could be a couple of years, that´s all??) Not too different from the black 335.

-

Seems to have a timing mark on the hand wheel? Looks like the back foot is just beginning to go down when it is at this position.

-

I will skip the front as you can see it is just taking off the thread guides and feet and needle plate etc.. This screw stud will come out by loosening the screw out from the back right hand side, the one you can see is for the curved plate that stops the spring. As you can see i have taken this apart to clean everything but if you were taking this off i think you could leave the stud and spring on with the plate and just take off the top screw and this one.

-

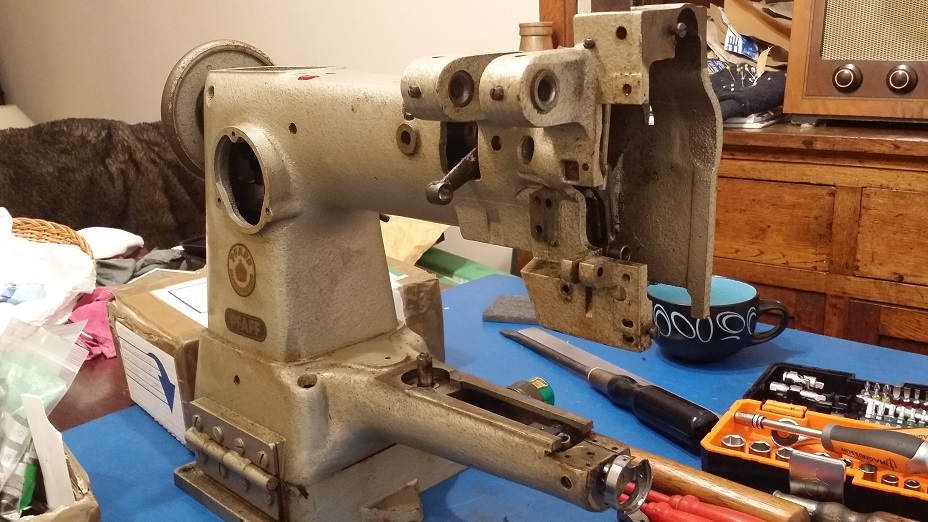

I have to start off by giving a big thanks to Soren (Danishman) here on the forum for his help, patience and very good packing and getting this 335 to me. This machine came from his barn find, as you know Soren found a barn full of Pfaff and other machines which the new owners did not want, so after looking at a couple of the pictures he sent i saw a 335 in the middle of the 145 land and said to Soren that this would possibly be worth while picking up. He said he was not interested in it as his wife already had a very good 335 so i thought i might be able to push it in the room "somewhere"??. This is a similar type of restoration as the first one in this thread, the big difference being a lot less rust and no broken parts to fix after posting. Here are some pictures of the tear down and build up. I am not a sewing machine tec and do this mainly to save a few bob and learn at the same time. So if you see me do something wrong in the pictures, do not copy it! hoho.. First the Box??? This is a very well packed machine.. 10/10 for Soren.. There was padding all around the machine and very tight, no movement. in the last picture foam had been taken out from the sides. As you can see, compare this with the black one and straight away you can see the difference. bottom of the stand is present, no broken parts, less rust better paint. But... it is a machine taken from a working place and stuck in a barn?? so Wattssap?? Hand turning is free wheelin Franklin so Let´s start by cleaning the parts that are rusty, this time i am NOT going to see if it sews first, because i am sure this will.

-

That looks like it is in great condition, well done.

- 9 replies

-

- seiko sk*

- singer 132k*

-

(and 2 more)

Tagged with:

-

Thanks for your kind words Glenn, I could do this kind of stuff all day if people would pay me hahaha... The pity was it arriving broken, as i would have liked to keep the original parts on it instead of changing them, but sometimes that´s what happens. For sure parts are the biggest problem if you don´t have a few donor machines lying around of similar type. Almost nothing metric fits. I did buy another cheap 335 a couple of months ago (thanks to Danishman here on the forum and his barn find) and took some pictures of the restoration but it was in a lot better condition and only really needed cleaning up so there was nothing really special about it in that sense. i will maybe just put them up here instead of starting a new thread??? Thanks again Glenn, Regards Jimi.

-

Hello Jirka, the S/n is - 4 141 405. I also have a newer (greenish) one but it has only 6 numbers?? - 603 218. maybe the paint is still covering the first number??. Regards, Jimi.

-

First attempt at a belt

jimi replied to Rockoboy's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Unless you put it in a cloth? I used to do this for french polishing. I would wash the wool, then tease it out until fluffy and put it into a old white t-shirt. you dip it or dampen it then you put it in the t-shirt making a ball and apply it that way. you only get the hairs on your finger tips form dipping. Well done Brian, looking good. -

¿¿Looks like someone filled in that spoked handwheel for heavier mass?? And Merry Christmas.

-

Yes, great job Plinker, Looks great!

-

Needle close to foot, Needle Bar Bad? Adler 69

jimi replied to arz's topic in Leather Sewing Machines

I had a similar problem with me old 29k and saw the metal was thin near one side of the needle hole so the needle clamp screw ended up pushing out the metal a little probably due to over tightening. I just took a punch and hammered it back in. Not saying this is the same case as yours but looks like it is worn on the inside. Also your needle will possibly be a little further away from the hook?? I personally would look for another needle bar. Or you could take out the needle bar and peen it back a little towards the hole?. -

is that ask a stupid question get a silly answer????

-

??? what is too expensive???