-

Posts

2,372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by immiketoo

-

Custom Coffee Tote

immiketoo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Shoot. Ritza. Stupid auto correct. -

Custom Coffee Tote

immiketoo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

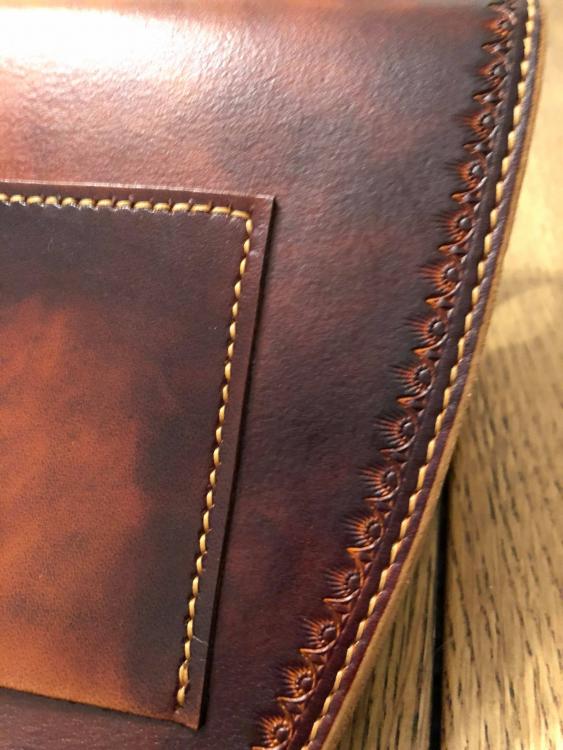

Thanks, man. Rita .6 mm thread and a combo of a Jueschke border stamp and a Barry King filler tool. Thanks, guys. Have to carry coffee for me and Natalie from the shop on my motorcycle. This fits the bill nicely. -

Custom Coffee Tote

immiketoo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Keith, my pleasure. Make sure you post it for all to see. -

Custom Coffee Tote

immiketoo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

It was an added bonus! It’s 5 oz with a 4 oz liner. I’d probably build a gusset on the pocketbacause there’s not a lot of room between the cups. -

Custom Coffee Tote

immiketoo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I use it all the time! -

Confessions of a leather worker or Why did I do that?

immiketoo replied to Albob's topic in Leatherwork Conversation

LOL! Well shit. -

Confessions of a leather worker or Why did I do that?

immiketoo replied to Albob's topic in Leatherwork Conversation

No problem. Just send me your address and all your spare cash -

Custom Coffee Tote

immiketoo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

And sometimes, they do just the opposite I really like how the stitching came out on this on though! -

Custom Coffee Tote

immiketoo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you. This is an easy project to make. Fun too! -

Quick change multi directional embossing blocks.

immiketoo replied to RockyAussie's topic in 3D Printers and Lasers

Shhhhh. If I had packaging that good, I wouldn't have to work so hard! -

Quick change multi directional embossing blocks.

immiketoo replied to RockyAussie's topic in 3D Printers and Lasers

That is some next level awesome right there. I hope to one day have that level of professional packaging. -

Custom Coffee Tote

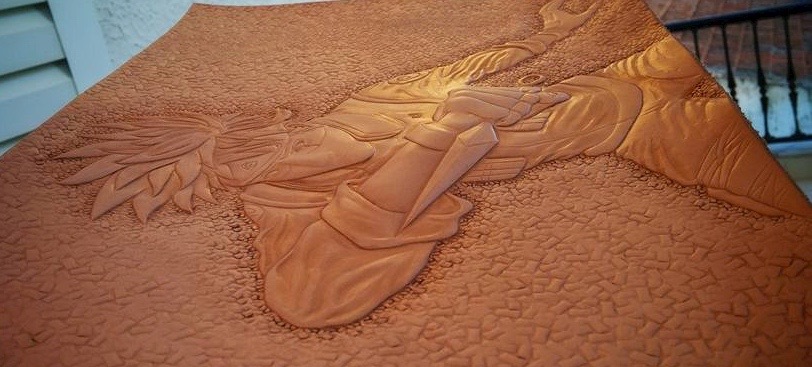

immiketoo posted a topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Here are some pics from my latest article in the Leather Crafter's and Saddler's Journal. Detailed instructions and a pattern are included in the issue, along with why this is a necessity in my life! -

Confessions of a leather worker or Why did I do that?

immiketoo replied to Albob's topic in Leatherwork Conversation

LOL! Truth. -

Confessions of a leather worker or Why did I do that?

immiketoo replied to Albob's topic in Leatherwork Conversation

Exactly! I always tell myself I'll one day have a wall for all my tools etc, and that I'll put them back immediately after using them. Pfffft. -

Confessions of a leather worker or Why did I do that?

immiketoo replied to Albob's topic in Leatherwork Conversation

So true... I have 20 times the tools I need to do my work. And I still see a new shiny one and think, hmmmm.... My confession: Mm bench is a mess. I clean it regularly but it always collects piles of stuff. I blame it on lack of space, but I must admit that it would probably be the same no matter what. -

For discussion purposes, inspired by a lot of silly info on the FB. https://vimeo.com/287673531

- 11 replies

-

- whynot

- buymoretools

-

(and 2 more)

Tagged with:

-

I agree with you completely. Anything else is uncivilized.

- 3 replies

-

- texas custom dies

- dies

- (and 9 more)

-

Cool Then you know what you're getting yourself into. I looked at starting a recognized internet guild with my FB page a while back, but I chose not to for a variety of reasons, some of what I listed above. A physical guild will be easier to manage all the way around.

-

Welcome from Greece!

-

In short, there is no standardization. The only consistency of any tool numbers is from a single maker. What a number two from on maker means something else entirely from another maker. I would try to go with the manufacturer who gives physical sizes in mm if you're unsure. Sadly, I have a half dozen awls on account of this very issue, and no two are the same, even those from the same maker. A lot of people learn to shape their own awl blades on account go this.

-

If they are the older versions with the longer shaft, they are about 40 bucks each.

-

how can you make airbrushed dyes penetrate deeper?

immiketoo replied to Jarednem's topic in How Do I Do That?

That doesn't really work. If its uneven to start, airbrushing will show it. Unless you go way darker than intended. Black is the great equalizer- 13 replies

-

- airbrush

- dye penetration

-

(and 1 more)

Tagged with: