-

Posts

874 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Rossr

-

Latest Knife and Sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yep my feeling too.. I got into the second row and I was committed. Ill fix it the next time I try it and attempt not to go redo this one Ross -

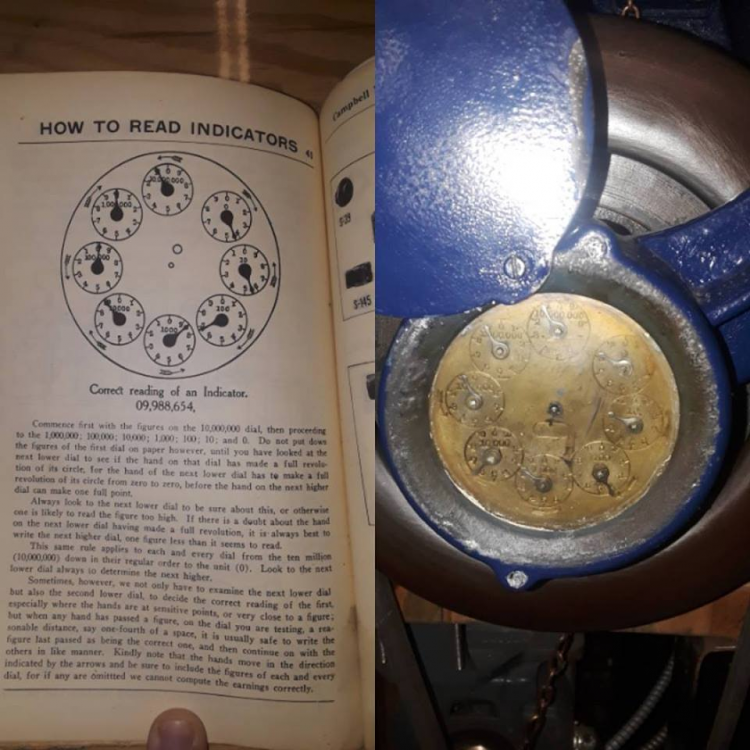

So I have a Campbell Randall Needle awl machine. I needed to replace the belt and this dial thing was in the way. After some study and a look at the really old book it appeared to be removable and didn't have any effect if I took it off and put back. So went too it. Belt fixed but learned a couple things. First off this must of had to be some kind of time or stitch counter. The book page at the end of the passage says about earning being calculated correctly. Also the screws both on the dial face and on the arm that holds it were covered in lead. My guess is so the user couldn't just take it off and manually move the dials forward. Which once it was off could be done easy. So does anyone know the history here? How old is this add on? I cant seem to find any pictures of it anywhere on the net. Other than the one page in the book about it, there isnt even mention of it in the schematics? Just curious id anyone knows anything? Thanks Ross S

-

Latest Knife and Sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

heheh Better revisit. or maybe I should lol. In this case its carbon steels so they can be heat treated. They make stainless also which you need a temp controlled oven to heat treat to the best of my knowledge. There is lots of debates on how god damascus is....my view is its not that great to hold an edge etc....but it is pretty and thats what folks like.....there are lots of spectacular steels out there now that hold edges better etc...but thats just me I saw the muleshoe online used like that so not my idea. and yes scales is what I thought too. Of course I want to redo it cause I feel they should touch more ....to look correct I -

@Rolandranch Upgrade that stool to wheels you wont regret it. I have a stool on wheels and i find myself wheeling around all the time! R

-

Thats a Gerstner wood tool chest. Pretty stuff right there. Nice looking space for sure. You happen to get that tool chest off ebay a few weeks back? There was one on there with a bunch of leather tools including like 31 kelly tool company stamps, Ross

-

How about the machine on the left too....someone is holding out on us there is a lot more shop here...pictures pictures

-

Here here I agree...more shop/workspace photos. I mean if I did it come on people you all can! Really is great to see them and regardless everyones space can give others great ideas Still loving all the different setups Thanks folks

-

Latest Knife and Sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It is not as black as it looks and it was still wet when I took the picture. It will get a nice reddish brown I hope when its dry. But I suspect monitor and the wetness make it look darker than it is....that being said mahogany is on the dark side imo. yep there are knifemakers out there that sell the damascus they make too. I stumbled on Alabama Damascus and it was nice stuff to work with...and yes it is very labor intensive to make it. some day I will try my hand Thanks for the kind words folks -

Finished this sheath off today and the knife as well. Need to put some finish once it dries. Knife is Damascus steel from Alabama Damascus, I profiled and shaped the blade, heat treated and etched. Brass bolster dove tailed into stabilized buckeye burl. Sheath veg tan with some light stamping and dyed with fieblings Mahogany. Always looking to improve if anyone sees anything Overall I was happy with the results Ross

-

bible cover Putting it all together: Bible covers for Christmas

Rossr replied to YinTx's topic in Books, Journals and Photo Albums

Looking good!!! I really like the dove on the one inside cover. just calls to me for some reason but it all looks great -

@YinTx There is one in the picture. I have never used it........suppose I should. Yes I try to set things up logical but I always seem to think there is a better way lol @bikermutt07 Amazing those cleats hold that kinda weight with all those paint cans in the video. Looks like a nice system. I could see a use for that.

-

Kings, I make custom knives and do leatherwork currently. I have been involved with other things though too. Even worked at a summer camp the last four years running the leather and wood shop. Not every tool is there...I mean the clicker press isnt pictured cause its in another place. I need a vacuum system for holsters etc. There must be some other stuff I am missing too.. I do not know what a french cleat system is but I will second the expensiveness of slat wall. I have it up cause I had access to a bunch of it for basically free. Otherwise...you would see something else there...or perhaps just the studs!

-

Jake, If you mean the Green machine in the one pic...what that actually is...is a Landis Line finisher. They were used for shoe making and you went from left to right to clean up the heels or soles, cut them down, sand them and then polish at the end. Now I use it for sanding and burnishing purposes mainly. Never made shoes and I cant say i need something that large. But it sure can be handy. A lathe setup as you mention would work nicely too

-

Thats a Randall and I am not sure how I lived without it before! I mainly use it for knife sheaths. Since I make knives. But plenty of other things have been done on it. Still learning how to use it but as I am sure you know those needle awl machines put down a nice stitch front and back

-

While the stamps have been a lot of looking and some luck on craigslist ebay.....the bulk of the pressy splitty punchy things were due to a shop I purchased a few years back. otherwise. I would have mostly just the couple desks and the hand stamps

-

Ok so here is most of the rest of the shop, debated posting it...but all you folks have shown your areas....so why not. Sorry the photos arent great they were just quick pics with the phone. Always looking for ways to improve the shop and all these pics have great concepts and ideas we can all learn from for sure! Thanks all

-

That is a good question, I don't really know what it is. It kinda reminds me of the desk tops in the chemistry lab but its grey not black. I was able to cut it with an abrasive blade in a circular saw. .....Still deciding if I like it for tooling. I used to have a hunk of granite that was a cut out from a sink but I like it being the whole way across the desk. Worse case I may do a full piece of granite down the road if this does not work out and budget allows. Btw before anyone thinks those are all new stamps and I am wealthy. The reality is craigslist and ebay has been good to me....or I spend way to much time looking for deals...you can decide lol! The center part where most of the stamps are has three wood blocks made at home and most of the holes were labeled with a label maker with the stamp numbers, I got them on a craigslist buy. I have been slowly filling in all the stamps over the past few years. I am down to about 40 I need to finish the numbers that are there.......Not that I need all them but its kinda a dream now!! Im guessing they used to all be there but not all where there when I bought it. Yep that desk has been around. The wooden one of the left is old too all wood except the top is formica...picked that up at auction for a $1. its great! Ross

-

Looks like great work to me. I am just a self taught amateur But dont be so hard on yourself your work looks amazing and just keeps improving. Just my opinion. Ross

-

Looking good yin!

-

Keep em coming guys and gals, always nice to see others makers shop spaces. Always a way to get ideas on set up too. Also BikerMutt and Sanch have been shopping at the same curtain shop lol real similar

-

I am self taught thanks to great forums like this and you tube videos. Just my opinion but starting out I see nothing wrong with tandy craftools. I dont have any pro craftools but have read some positive things. It seems the progression as you get better and learn is to get the more expensive stamps like Barry king. From what I have read and seen in posts they make a sharper impression in a lot of cases. I have some of the older craftools and they do make a nicer impression then the newer ones. Ebay is a good place to grab a lot of stamps too Biggest thing to me is get started and try things and learn as you go along Welcome to the Journey its a fun trip Ross

-

-

couple of us over in chat talking leather if anyone is inclined

- 100 replies

-

Custom Knife and Sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks all. I tend to be a perfectionist so all I see is the mistakes or at least in my eyes the mistakes. So I appreciate the feedback Ross