-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garypl

-

I use a similar process, but I use an arbor press to push the stamps into the leather. Works great and you don’t ever have to double hit the stamps, eliminating risk of a blurred image. Gary

-

Here are some photos - I use this bench for reloading, but it is solid as a rock and would also work well for leatherworking.

-

Susan, If you have a space on a wall, you can build a very sturdy workbench by screwing a horizontal beam to the wall (2x4" by however long you wish to make the table). Screw the beam to the wall at the height you want, then make a table top frame out of 2x4" lumber and top it with plywood or whatever material you wish to use. Just make certain the top is at least 1.5" thick. Working on the floor, make a couple of support legs from 4x4" lumber and lag bolt them to the underside of the table top in the two corners. Cut the legs so they are the proper height that when the top is set onto the wall beam, the legs will support the underside of the top. Now have someone help you flip the table right side up and set the rear edge on top of the wall beam, bolt the top to the beam, build a shelf underneath the table to strengthen it and provide storage space. This sounds more complicated than it is to build and I will post a few pictures tonight when I return home. It makes an extremely sturdy bench top and the cost is minimal. Only caveat is you must have some blank wall space to attach the bench/table top. Gary

-

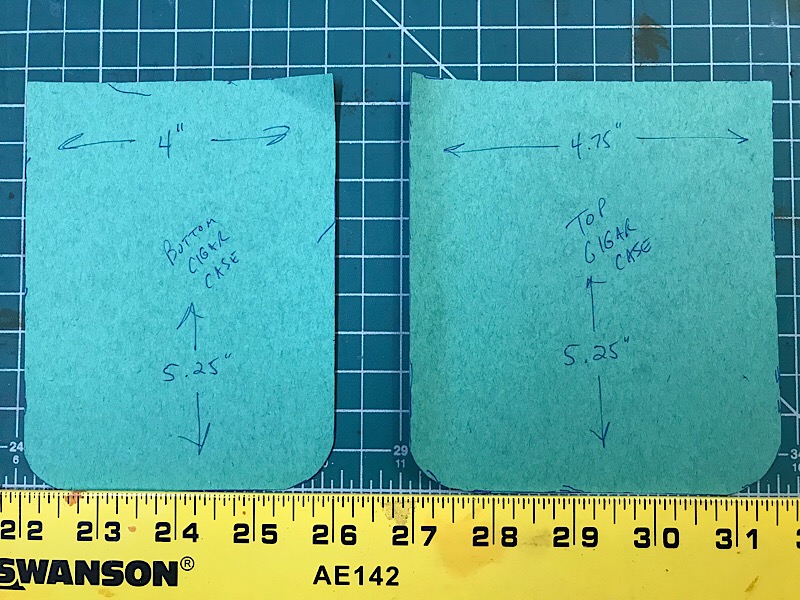

Cigar & Cigar Cutter Cases

garypl replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks! I enjoy making small items for friends and family - just started making and selling shooting accessories for some of the guys at my gun club that have seen my work. I’m not interested in turning this into a real job, but nice to sell a few pieces now and then to support my hobby! Gary -

Cigar & Cigar Cutter Cases

garypl replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I highly recommend the air brush from Harbor Freight for dyeing and spraying finishes where I am not concerned about pinpoint detail work. I use the #93506 air brush - cost $9.99 and there are always 20 or 25% discount coupons online. I:like it because it comes with 5 paint cups that you can switch without having to clean the air brush. I also use the Harbor Freight #62994 brush, but you have to buy extra paint cups and you have to clean the brush after each use. Keep a straight pin handy to unclog the vent holes in the paint cups - they tend to accumulate dried dye and finish and won’t spray if they become clogged. Either brush sprays Resolene thinned 50/50 with water and they do a great job. Gary -

Cigar & Cigar Cutter Cases

garypl replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hey Carson, I use a Cowboy CB4500 and very much enjoy sewing on it. I am thinking I will get a smaller machine for very thin leather so I can use thread smaller than 138. I bought the machine from Bob at Toledo Sewing - check his banner ad here in the forum. Gary -

Cigar & Cigar Cutter Cases

garypl replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

Ben, when applying acrylic paints, in addition to several sizes of paintbrushes, I also use small plastic bottles with very fine steel tips to apply paint along borders. I outline the area using the squeeze bottle because it allows a very fine line of paint to be applied. Then I can paint in the interior area with brushes. The steel tips are not much thicker than a hypodermic needle, so you have to thin the paint so it will flow through the tip. Gary

-

Congratulations Jake on taking your first step to a dedicated workspace! That table doesn’t look stiff enough to pound on though - where do you do stamping, rivet setting and other activities that require a very solid surface? (Also, coming from someone in Georgia, I don’t think I could handle the cold up there!) Gary

-

Welcome Ben - you are doing well and will keep getting better! So many talented people in this forum that we can learn from and hopefully we can give back to,others! Gary

-

Mark, I think you did a great job on your first wallet! As far as fabric used for lining, I prefer thin leather like pigskin - then you won’t have to deal with cement bleed through. Only other comment is that I think the stitching would look better using 90 degree turns at the corners instead of what looks like a 45 degree angle. Every project is a learning experience and you are off to a good start! Gary

- 10 replies

-

A Christmas/Birthday Belt

garypl replied to JMcC's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

James, I should receive it at the end of the week. I am in the middle of carving a shotshell pouch and have already carved two oak leaves, so I am going to wait and finish the additional two oak leaves with the new knife! I’ll post results when I finish. Gary -

However you did it, it looks great!

-

GP100 Field Holster

garypl replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Josh - I will try the velum paper! Gary -

A really productive hobby

garypl replied to CrackedPennyLeathercraft's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for your reply! The other advantage to using a welt (besides protecting the stitching) is to allow a little more clearance between the leather and the blade so it is a bit easier to insert and remove the knife. We learn a little bit with every new project! Gary -

GP100 Field Holster

garypl replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Josh - when you design a new pattern, do you use heavy paper or is there another type of material that works well for pattern design? I want to try to design a holster for a S&W M64 and seeing your holster is for a similar revolver (Ruger) got me thinking about getting started down the right path with this! Gary -

A really productive hobby

garypl replied to CrackedPennyLeathercraft's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's a nice sheath - noticed you did not stitch all the way up to the hilt on the cutting edge side - is this to allow clearance for the widest part of the blade? It looks thin - did you use a welt to keep the threads from contacting the blade? Gary -

GP100 Field Holster

garypl replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Really nice work - is that your own pattern? Gary -

A Christmas/Birthday Belt

garypl replied to JMcC's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That's a good idea, so I looked at the LW website and then figured if I am paying $55 for a blade, why not get the complete knife for $110? I ordered the brass body knife and and extra blade - looking forward to testing it out. Gary -

A Christmas/Birthday Belt

garypl replied to JMcC's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

You make some good points Yin. I don’t do this to make money, it’s just an expensive hobby! I’m also a tool junkie, so I will probably get one to see what I am missing. -

Sig P320 Holster

garypl replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is a beautiful holster! -

LCP pocket holster, non-printing

garypl replied to alpha2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You are right, in a loose pocket mine tends to drop down on the grip end. I am going to try your design. Thanks for sharing! Gary -

LCP pocket holster, non-printing

garypl replied to alpha2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Mine has the built in laser (that I never use) so maybe a bit bulkier under the barrel. I made a small pocket holster but it is difficult to raw without pulling the holster out and using two hands. For this reason I normally just keep it in my glovebox. Your design might just be the ticket! -

A Christmas/Birthday Belt

garypl replied to JMcC's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I looked at the LW website and the swivel knives look good. I am using a couple of Tandy knives and seems I am constantly stropping them. I am struggling with deciding whether or not using a better quality knife will make enough of a difference to justify the cost. Would be nice to test drive one before committing to the purchase!