-

Posts

391 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by SARK9

-

Seiko Dl-328 - 2 Needle Compound Feed?

SARK9 replied to Constabulary's topic in Leather Sewing Machines

This is as close as I can get you with a cursory search- Most of this stuff is a copy of some other's original. http://www.allbrands.com/categories/282/39902-consew-328rb-2-1-4-double-needle-split-bar-walking I'd drive a few Km to pick it up if the price was attractive, but probably not to the Eurozone! -DC -

I could not get your pictures to enlarge, but it looks (from the thumbnails) to be similar to the Mitsubish LS2 series of machines. Do a search on the the Mitsubishi offerings and you will probably find one that is a 100% match. -DC

-

If you are able, post a few pictures of the machine. Many of the industrials are copies of other maker's originals to some extent, so its design may suggest a *family* of machines that is more well known. -DC

-

That is an external clutch and it *looks* like it may give a very slight overdrive of the motor speed, rather than have a reduction. The motor pulley and clutch input pulley don't look too drastically different in size (a small speed reduction with this pair), but the clutch output pulley is quite a bit larger, and will probably overdrive the heck out of a typical handwheel pulley. -DC

-

Would Appreciate Your Advise On Restoring This Singer 45K25

SARK9 replied to Evo160K's topic in Leather Sewing Machines

With some of the material you need to sew in the machine, try to watch the loop being formed on the upstroke and see if the thread's behavior and its relationship to the hook suggests a possible cause for the "chopping" effect. It *sounds* a bit like the hook is clipping a squirrelly loop caused by some odd flexing properties this stuff may have. You may have to adjust the machine's clearances to the extent that your machine becomes "dedicated" for use with that one thread type. I "hear" is a bear to sew with properly, but I've never tried it. The shards and sheds from fiberglass and kevlar type threads are incredibly abrasive, and will find their way into everything. -DC -

That style of external clutch motor has the pulley integrated with the movable clutch pad, at least its that way on one I have that is very similar to the one pictured. Replacing it with a smaller drive pulley may be non-trivial. On the plus side, the unit I have is the most controllable clutch motor I have used, though it was still a source of noise and other annoyances. A servo swap brought much happiness. -DC

-

>>Now I'll go and look up what a latch opener is and what adjustment my machine may need, haha.<<, Errr... bobbin case opening lever. Error Level: Brain shorthand. -DC

-

Hi Uwe- In the video you posted....the latch opener on that machine looks like it needs adjusting....proving that a video DOES help diagnose this sort of issue! -DC

-

Bottom Mechanism Dont Move (Brother Ls2-B837

SARK9 replied to Christoffer's topic in Leather Sewing Machines

Gottaknow quoth: "I used to remove them so the operator had to call for help rather than just keep resetting the machine without clearing the jam. Save a lot of hooks and other parts that way. If I recall, I mention that in the video." I did not realize this was your video, or I would never have linked to it without attribution. Thanks for all the excellent information you share on this forum and elsewhere! -DC -

Bottom Mechanism Dont Move (Brother Ls2-B837

SARK9 replied to Christoffer's topic in Leather Sewing Machines

Here is a video of a similar machine with some things to check and a view of all the operations of the clutch. -DC -

Bottom Mechanism Dont Move (Brother Ls2-B837

SARK9 replied to Christoffer's topic in Leather Sewing Machines

Make sure you are turning the handwheel *backwards* with the button depressed. This would mean the top of the handwheel is rotating AWAY from you, or if you are looking at the handwheel from the right end of the machine, you would turn it clockwise. -DC -

Bottom Mechanism Dont Move (Brother Ls2-B837

SARK9 replied to Christoffer's topic in Leather Sewing Machines

Many machines similar to yours employ a safety clutch which trips out in the event of a jam. After ensuring there is no more material caught in the hook or bobbin area, you could try depressing the spring loaded button located about halfway back on the flat part of your bed, then feel for it to engage/click as you rotate the handwheel backwards. Release the button, then cycle the machine forward by hand to see if it is re-engaged and operates freely and in time. Disclaimer: I don't have that exact machine; your mileage may vary. -DC -

I would try a 19 or 20 needle, and look closely at the hole in the inner foot. See if the needle has enough clearance as it cycles through a stitch; ditto as it enters the hole in the feed dog. Some of the 563's I have seen have the needle position set up VERY far to the left in relation to the needle plate and feed dog, to the point you have to use a center foot with a somewhat larger hole. -DC

-

Strong Motor For Table Top Mounting? Dc?

SARK9 replied to Nessmuk1's topic in Leather Sewing Machines

I've done something similar with a gear reduction to a pulley reduction, but it was for a Q&D single project. Using a 1.6 amp domestic sewing machine motor, it had plenty of power, and with a good foot controller, it was easy to do individual stitches. However, too much load from thick material is going to cause belt or stop motion washer slipping. You may want to look at the toothed timing belt type arrangement used by Sailrite, or check out the generic timing belts and pulleys available from power transmission suppliers. I think I remember seeing someone who had made a very nicely executed *portable* Juki-LU563 which used a commercially available gear reduction motor, but when I looked up that motor it had been discontinued. Anyone that considers the head of an LU-563 "portable" is a better man than I! -DC -

Whichever pulley you connect to the machine head's pulley (be it a speed reducer or the motor pulley) it needs its shaft centerline to be located a bit behind the rotation point of your table hinge pins for the machine head to tilt back normally. -DC

- 5 replies

-

- 111w155

- diy sewing table

-

(and 1 more)

Tagged with:

-

If your photo is of the actual machine in question, it looks to be in good shape. You will want to SEE what model it is in reality. The price (and value) depends on if it has any issues, and your confidence in doing your own repairs and upkeep on it. Like any used machine, it needs to be looked over carefully for gotchas....That is the only way to determine if the asking price is reasonable. Machines of that type/class are not uncommon in that general price range. -DC

-

Help I Think I Stripped A Gear Or Something?

SARK9 replied to Carrieanna1172's topic in Leather Sewing Machines

The machine's bobbin/hook assembly is probably completely out of time, so simply re-establishing the gears in mesh will not fix the problems now. It must have had a set screw that wasn't completely tightened. Timing these machines is not too difficult if you have good instructions and want to learn how. Take it one step at a time in the correct order. As long as you check the operation by hand power only, and take it easy, you can just do it over until its perfect with no harm done. -DC -

Can Anyone Identify This Sewing Machine Brand Name?

SARK9 replied to llucas's topic in Leather Sewing Machines

Dead ringer for a Consew model 230 with the reverse lever missing. -DC -

>>Moving the motor towards the rear of the table does not let you use the belt tension adjustment feature on the motor.<< Moving the motor towards the rear allows you to mount **your speed reducer's small pulley** in a location back behind the hinge point of the machine head, allowing normal tilting, as has been stated several times. The "tension adjustment" (?) works perfectly normally, it remains a simple function of the correct belt length as is usually the case. Selecting the length of the short belt (running from the motor to the reducer's large pulley) does become less forgiving, as the motor is adjusting away in a reduced arc, but its not difficult to work out. Frequently, the 3L420 belt that comes with a stock clutch motor seems to be just right for a servo with a 50mm pulley when the speed reducer is mounted towards the rear as shown. -DC

-

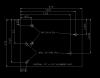

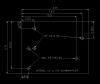

Ugh. I just noticed that the program hadn't saved the last dimensions I added when I attached that file of the plate measurements. Here's the finished print. This is a picture of the whole assembly on a Singer 20U33 I just got for doing some wide zigzags. Notice I have the speed reducer belt disconnected, as the latest motor I bought *seems* to not need any help at all with the speed control whatsoever. They either corrected the shape of the optical controller blade or I got a one in a million copy. I have replaced the stock 90mm pulley with a 50mm motor pulley I made. The max RPM is set at 4500 and delay is zero, but its easily able to do one stitch a lifetime if I want. -DC

-

I've done several clutch motor/servo swaps and with the typical narrow industrial tables, my solution has been to install an offset plate that mounts to the original carriage bolts in your table, but offsets some new mounting studs to the right side to compensate for the extra width of the reducer pulley. This arrangement also lets the motor set back far enough that the large pulley won't interfere with the motor pulley, and allows normal use of the belt cutout and the tilt-back of the machine head. -DC

-

Specs for the 3L pulley: Effective Outside Diameter in inches: Under 2.2-- 32deg. width at full dia .360 2.2-3.19-- 34 deg. """"""""""""""""" .364 3.2-4.2-- 36 deg. """"""""""""""""" .368 over 4.2--38 deg. """"""""""""""""" .372 Depth of groove .406 -DC

-

When you look for v-belts on a website or catalog, you will see them listed as a "3L-390" or 3L-395". The -390 is a 39" belt, the -395 is a 39-1/2" belt. Be sure to get the best quality available for smooth, vibration free running. The guys on this site that have sewing supply shops probably have known good brands. -DC