-

Posts

391 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by SARK9

-

The upper portion of the Mitsubishi CU-865 *looks* identical to the 105....I expect the thread path is the same. -DC 8-13.pdf

-

Just from looks, it may be that there is actually an *offset adapter* attaching the foot to the bar that could be replaced or modded....you need to determine where the needle position center needs to be in relation to the presser foot bar, and whether this machine does a right home or left home like several makes of ZZ machines do. -DC

-

Many walking-foot triple-feed machines used for binding are equipped with the horizontal-only feed dog movement, with the Pfaff 335 and its many clones probably the most familiar. I have a Mitsubishi CU-865-22 which has this system, and it really gives me no trouble feeding the range of materials I usually take to it. Some of the binding combinations are NOT particularly easy to feed if you think about it.....The elliptical or 4-motion feed dog movement is probably more forgiving in some instances, but it all depends on what you are going to be sewing. The way the center foot moves on a needle-feed walking foot system lets it press the work to the feed dog and travel with it, which is a reasonably effective transport. Give it an audition as is and it may surprise you. -DC

-

Most industrial sewing machines use a "3L" belt, which come in half-inch increments. Example: A 32" belt will be a 3L-320, a 32-1/2" would be a 3L-325. -DC

-

The "laminate trimmer bits" with a ball bearing guide do an excellent job. The important thing to remember is to carefully inspect the inner edges of the hole which will act as the guide for your cutter, since it will duplicate any defects present. An automotive body filler such as "Bondo" does an excellent job. I much prefer the older plywood from salvaged tables for my own stuff, as there is no comparison between the older higher-density plywood and the pressed rubbish being sold now. -DC

-

I was looking at the decal where it says "Foot lift output 24V" and thinking hmmm.... -DC

-

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

SARK9 replied to Uwe's topic in Leather Sewing Machines

Nice job, and stainless is definitely the way to go! -DC -

Juki DNU-241, Consew 206rb, request for advice

SARK9 replied to pattyharrington's topic in Leather Sewing Machines

I'm seeing several spec sheets on the 30" 158 which list the machine's weight as 108kg...nowhere close to 400 lbs. -DC- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

SARK9 replied to Uwe's topic in Leather Sewing Machines

Heck. I already had a 2-1/2" bar of 6061 chucked up to play with.... I didn't have a Pfaff 335 to verify dims with, so I sort of ASSumed the small arm machines shared the arm diameter....as even with the M bobbin, they still call the CU- 865 a "small arm". -DC -

Juki DNU-241, Consew 206rb, request for advice

SARK9 replied to pattyharrington's topic in Leather Sewing Machines

One reason they were never as popular as the LU-563's.....the 230 lb machine head! -DC- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

SARK9 replied to Uwe's topic in Leather Sewing Machines

-

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

SARK9 replied to Uwe's topic in Leather Sewing Machines

Q&D sketch- -DC Mitsu_cap.bmp -

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

SARK9 replied to Uwe's topic in Leather Sewing Machines

The business end of your 335 does look slightly different from my 865, as well as the other 335 pics in the thread. On my Mistu, the cap can essentially be regarded as a blind-ended 50mm O.D. turning bored to wall thickness of +/-1.75mm, with the location of the cap slide edges generated by making a full width, straight-across milled cut at +/-42.0mm taken at the diameter. The length on mine is 28.75mm, and the front recess for the mechanism under the needle plate is at 38.0mm. I can get with a cad program later and possibly put it in a form that makes sense. -DC -

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

SARK9 replied to Uwe's topic in Leather Sewing Machines

I would bet the closed cap off the Mitsubishi CU-865 would fit it, since everything else on the arm assembly seems to be a 1:1 copy of the 335. The only problem is, they are probably an order of magnitude more scarce than the Adler 69's. You never know what you might run into, however. -DC -

Juki DNU-241, Consew 206rb, request for advice

SARK9 replied to pattyharrington's topic in Leather Sewing Machines

One of the machine historians can jump in here, but the familiar casting form of the 111w series goes back to the 111w100 at least, and probably further, as this upper casting mold was recycled on a zillion other Singer models, as well as the Seiko-Consew & Juki incarnations. The Consew 224/5/6 was pretty much a copy of the 111.xxx Singer models ending up with the Singer 111G156, with few significant improvements really. The Juki LU-563 was probably the most "improved" of the copies I know of, with its larger hook and a couple of other upgrades. As far as the 206-RB stuff, its interesting to note that Singer reversed these copy dynamics when they rolled out the "531-8BL" with their own decals and paint job on it. Imitation is the sincerest form, etc., and I'm sure Seiko was heavily flattered by the marketing rights fee. I personally wish Juki had made a Singer 144 copy as popular as the 563 while they were at it.... -DC- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

I have a really nice shiny Mitsubishi *Limi-stop-Z* servo motor unit that came with one of my Juki machines, complete with all the solenoid valves, positioners, trimmers, pneumatic lifts/reverse actuators, plugs and plumbing one could ever desire. The documentation for programming it is still readily available. One intriguing feature is described as a sort of "non-contact" electronic clutch which has a progressive sensor to attach to the foot pedal....a cyber-feathering prosthetic clutch solution for pedal-impaired klutzes like myself, thinks I. I have compressed air and an old school roto-phase always available here....but that type of annoying motor still has to run all the time. I broke weak and went with an off-the-shelf servo from one of our Asian trading partners...a Consew CM-1000 in this case. Ain't nobody got time for dat. -DC

-

Actually the simplest (and probably cheapest) way is to get a *static* phase converter like this: http://www.ebay.com/itm/HD-3-4-1-5-HP-Static-Phase-Converter-Mill-Drill-Saw-USA-MADE-Single-to-three/281866254808?_trksid=p2141725.c100338.m3726&_trkparms=aid%3D222007%26algo%3DSIC.MBE%26ao%3D1%26asc%3D20150313114020%26meid%3Daf94b720aabb4b93839885f6f203f534%26pid%3D100338%26rk%3D10%26rkt%3D30%26mehot%3Dpp%26sd%3D391284079818 ...which robs you of all the cool stuff you can do with the VFD but costs less than half the price. Disclaimer- I've not used this brand and use this ad STRICTLY for illustration purposes of a generic solution. I HAVE used static phase converters in a light industrial setting on low voltage 3ph MOTORS ONLY, from 3-7 HP, with good results. I have NO idea what the connections on your electronics require in this case. -DC

-

Edge Guide for Consew 225 (and clones)

SARK9 replied to KeithHideWorks's topic in Leather Sewing Machines

-

Edge Guide for Consew 225 (and clones)

SARK9 replied to KeithHideWorks's topic in Leather Sewing Machines

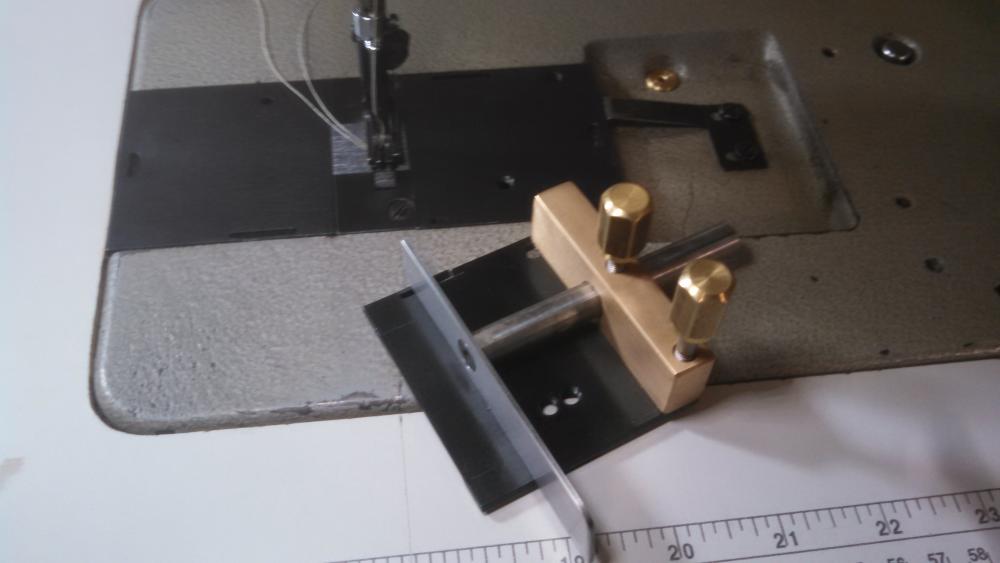

I've never really cared much for the magnets as an edge guide....most of the ones I've played with all look like they will tend to abrade away the paint if they are strong enough to be reliable...just from the friction of making position adjustments over time. I've been using a captain obvious quick-change plate that has a set screw on the back end...it secures the plate into the bobbin cover dovetails for the machines like the 225/226 or 111w types that don't have a spring lock like the Juki 563's etc. use. -DC -

I think I'd drive a bit farther and look at something like this one.... http://hartford.craigslist.org/for/5959643622.html This Seiko has a walking foot (the Singer 211 is a needle feed) plus the bigger *M* sized bobbin... and its arguably one of the best in class for its type. -DC

-

The fact that its not electronic/digital doesn't necessarily mean its old or totally inferior. There are "servo" motors sold currently that are a sort of re-hash of the basic DC brushmotors with a rheostat as a speed limiter, as seen on domestic machines from the 1970's like the White model 970. If yours works at all, its probably fine for now. -DC

-

I pretty much wind all my own...its hard to get prewounds in the color/size/style and materials I use, but I do synthetic fabrics as a rule. The M style bobbin is pretty popular and the colors needed to do most leather should be less an issue. -DC

-

If you look up a Juki DNU-241 or a Nakajima 280-L I think you will find the info you are after. -DC

-

Singer 29k171 "Another journey to the unknown"

SARK9 replied to jimi's topic in Leather Sewing Machines

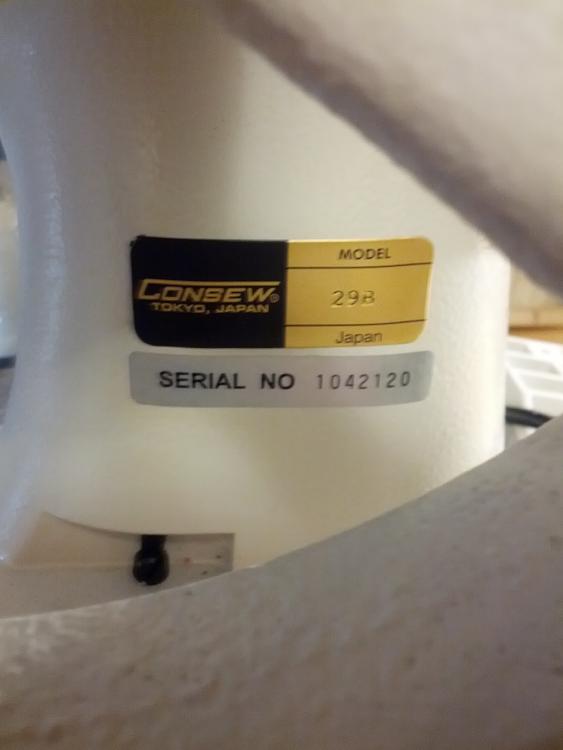

Consew makes what they badge as a "29B" these days, which is a short arm/large bobbin machine equipped for the handwheel to be mounted in either position. A couple of other importers also handle similar models, long or short arm. I've not seen exactly which components of their castings were copied to use original Singer parts, but it may open up a new avenue for you to explore. I couldn't wait out the avaricious hardware speculators in my area, so I bought a new Consew, since I needed its capacities. I replaced the hook which came with mine with a high-quality Japanese version made for an original large-bobbin Singer, and so far all the parts made for Singers have been drop-in fits. -DC -

Cast Iron Again - Pearson & Bennion / BUSMC A1

SARK9 replied to Constabulary's topic in Leather Sewing Machines

I would investigate a low-temp cad-free silver solder for safest results on a thin section like that....welding may be overkill for the application. With care, the repair will be close to invisible (if you have the complete missing chip), and the high-percentage silver solders are impressively strong. -DC