-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Willie0

-

Recommendations for dremel burnishers

Willie0 replied to Tinkerton's topic in Leatherwork Conversation

I bought a set of the ebay burnishers that go on a dremel. Half of them unscrewed (threaded wrong direction) and my dremel sounds weaker now. Might be better off looking a different direction, just my 2 cents. -

-

I have subscribed to the Weaver youtube channel and have been watching these videos as they come out. They are well done, easy to watch through to the end, and informative. Thank you for producing them.

-

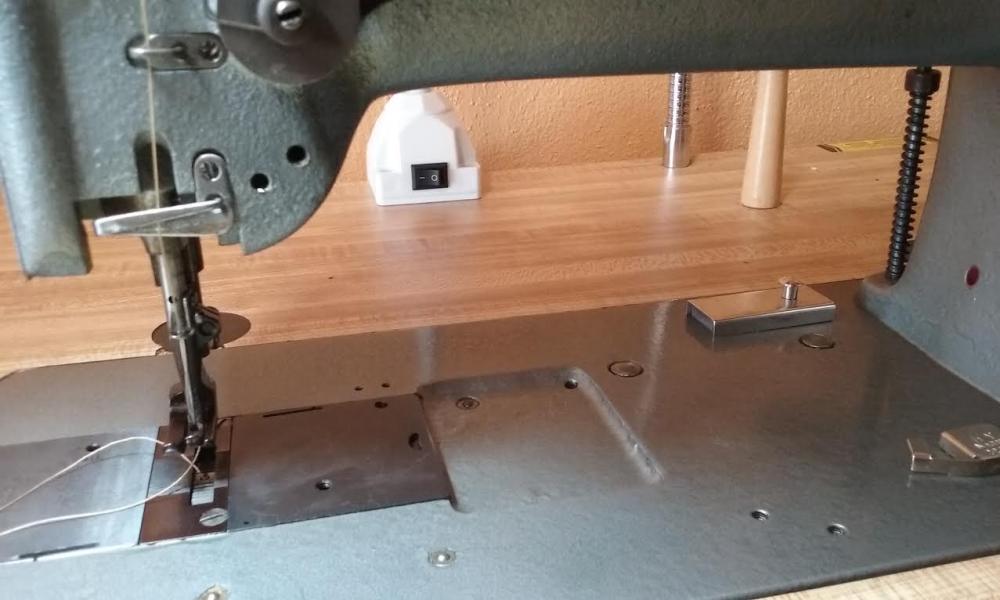

Gosh you might get more feedback on this one than you asked for. For the big stuff, I have an awesome Class 4 Cobra. After buying that I got an old Singer 111w155 and added a servo motor. This machine gets alot of use. Everything from canvas to light leather, denim and blankets. I used my dremel to open up the toe of one foot for better visibility. It also has a Sailrite binder which is attached with an ebay bracket. Next I have a 1960's Morse for fabric. Also a Singer 66 treadle machine, mainly for fun, but I have sewn on patches with it. These machines are all wonderful in their own way and highly recommend them all. Sometime I may replace the 111w155 with another table model that has reverse,

- 42 replies

-

- leather sewing machines

- what machine is used for leather

-

(and 13 more)

Tagged with:

- leather sewing machines

- what machine is used for leather

- professional leather sewing machine

- which leather sewing machine is best

- best machine for sewing leather

- sticky???

- sewing leather

- best antique leather sewing machine

- best new leather sewing machine

- leather sewing machines makes and models

- what machine do the pros use

- leather sewing machine reviews

- leather sewing machine opinions

- best sewing machine

- leather sewing machine question

-

Cleaning feed dogs after sewing waxed canvas

Willie0 replied to Willie0's topic in Leather Sewing Machines

Thanks! -

Hello, I was wondering what product to use to clean my feed dogs after sewing waxed canvas? I have scrubbed them with a toothbrush and machine oil, but they still seem a bit dingy. I can't stand smudging my projects after sewing waxed canvas things. Is it possible to clean them up with removing them? Thanks in advance for any ideas.

-

Geometric Stamped Wrist Cuffs

Willie0 replied to immiketoo's topic in Collars, Cuffs, Leashes and Leads

Absolutely beautiful! -

They have treated me very well, I have no complaints. If I order from different suppliers, it is generally because of the difference in distance.

-

Those are seriously impressive!

-

How to attach a binder to a Singer 111W155?

Willie0 replied to Willie0's topic in Leather Sewing Machines

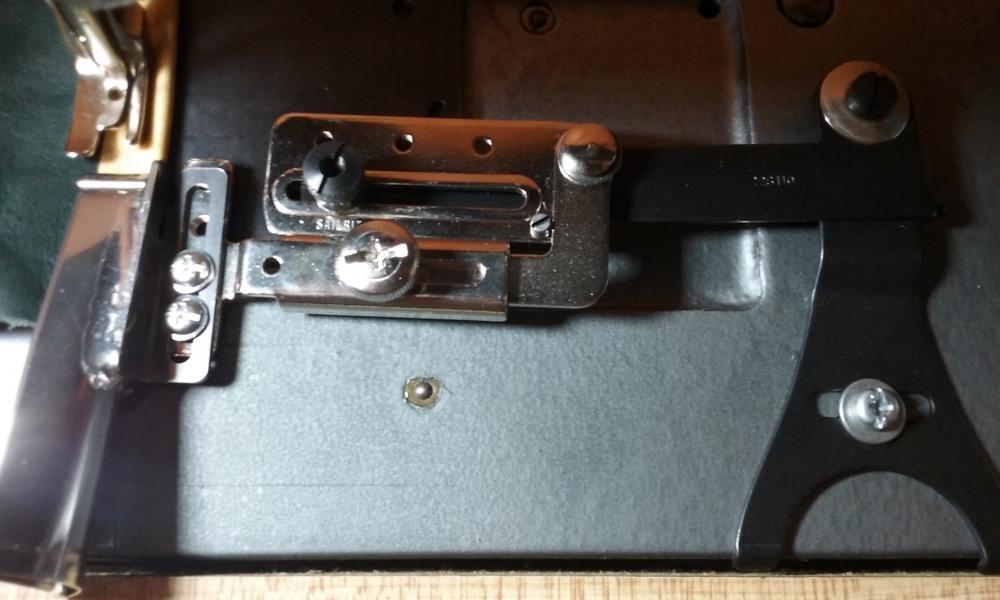

The thought of drilling holes was too daunting, so I ended up buying an attachment bracket off ebay. The Sailrite binder hooked up to the bracket sans the attachment's chromed part with a touch of dremel grinding. So far this is working very well, with a solid feel. This seems to be a solution that will work nicely for my hobby projects. Since the Sailrite is only held on with one screw, it no doubt would not be a good way to attach the binder for someone who relies on this professionally. -

I really wish that I had purchased the Al Stohlman case making books right when I first started. It would have saved countless hours of internet searching and struggles. Also Leather Tools and The Art of Hand Sewing Leather are very useful.

-

New Seiko STH-8bld-3 - somewhat off topic

Willie0 replied to leecopp's topic in Leather Sewing Machines

I think alot of people will be jealous reading this. -

How to attach a binder to a Singer 111W155?

Willie0 replied to Willie0's topic in Leather Sewing Machines

I can see how that could be superior because the binder is not affixed to the moveable plate. Thank you to everyone who has given me some ideas today. -

How to attach a binder to a Singer 111W155?

Willie0 replied to Willie0's topic in Leather Sewing Machines

I looked closely at this picture from another thread: New to industrial sewing machines Juki LU-562 Could it be that simple? -

How to attach a binder to a Singer 111W155?

Willie0 replied to Willie0's topic in Leather Sewing Machines

-

How to attach a binder to a Singer 111W155?

Willie0 replied to Willie0's topic in Leather Sewing Machines

That looks very nice. I have binder envy. I am still trying to think of ways to rig this up so I don't have to mess with taking the plate to a metalworker. -

How to attach a binder to a Singer 111W155?

Willie0 replied to Willie0's topic in Leather Sewing Machines

That bracket looks interesting. Do you know where you got it or what it is called? -

I was wondering how to attach either a SailRite swing away or a right-angle binder to a Singer 111w155. The right-hand plate has only one screw hole and requires two. Is it possible to use a plate from another similar machine model that does have the two holes? It would be very nice if there is a solution that does not include metal work! This forum has been immensely helpful, and any suggestions would be incredibly appreciated.

-

I just installed a servo from Toledo Sewing on my 111w155 and am very happy with my speed control. It is possible to go a stitch at a time with practice. A speed controller would be nice, but I don't feel the need for one on this machine.

-

Homemade tools and ways you have saved money on tools

Willie0 replied to JenGranger's topic in Leatherwork Conversation

This guy has some amazingly creative ideas: http://asailorsleather.blogspot.com/2008/10/homemade-leather-tool.html -

Keychain Sap (Lead Filled)

Willie0 commented on Bonecross's gallery image in Our Leatherwork Galleries

-

Searching for Hooded stirrups helps too. I made these awhile back for a Natural Ride pad. The covers aren't traditional, but they are secure.

-

Well, here it is. The body is just 3 identical pieces, a shorter and longer pieces for the flaps, a gusset. Inside the holster goes against my body and the magazine pocket faces it in the same compartment. I didn't need to tool the holster part, but couldn't resist. Sorry for the picture quality. You can see that I have a hard time with highlighter muddying up when I add finish, no matter how long I let it dry.