Windrider30

Members-

Posts

806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Windrider30

-

Choker/Collar/Necklace

Windrider30 replied to JMixx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Great idea to join it together! Really LIke this -

Love the work how hard is the hair on hide to work with? My wife says it makes her teeth go funny just looking at it and there is no way I would be allowed to have it in the house lol...a new way to torment the misses added bonus for wanting to work with this stuff lol

- 22 replies

-

- hair on hide

- tote bag

-

(and 2 more)

Tagged with:

-

that is some insane tooling!!

-

three to four oz leather works great for tophats not to hard to work with and with it being veg tanned its stiff enough to hold up and easy to lace as well as dye what ever colour you want!

-

My first Cobra Class 18 Creation

Windrider30 replied to westernatelier's topic in Clothing, Jackets, Vests and Chaps

Holy crap this is amazing!! great work!!!- 6 replies

-

- cobra

- cobra class 18

- (and 6 more)

-

Now that is a damn good idea will have to see if i would still need to line the leather jacket bug that is a really interesting idea!!!

-

I am honestly thinking about leaving the arms uncovered with sheep skin...and that is a good idea to try and figure out how to figure out the surface that I will need thanks for that..and its for me will be brown bison still have a lot to learn but was wondering how much sheep skin to buy that's the biggest issue

-

As this was a test with shit leather I was not too worried about it and just used the rivets I had on hand which to be honest were a little small for what I needed but it was a fun project

-

Ok have a really stupid idea in my head that I want to do, a full bison jacket lined with sheepskin like the old bomber jackets. My question is how many sheep skins should I order as I really do want to use the sheep skin as a liner though winters here in Australia are not THAT cold would still like to be toasty warm in the winter, and sheep skin is easy to find here!!

-

Thanks but thank god when I tried it on that no one was in front of me when I sat down rivets can only hold the fat back for so long, one came shooting off screaming freedom and if someone would have been infront of me they would have had a hole clean though them!!! There are two methods well three, you can go on etsy and find corset patterns and use those, you can use the duct tape method (my perfered method) and you can learn to draft corsets (I still suck at that lol) you can go to http://foundationsrevealed.com/ they have a shit ton of articles on corsets, how to draft them everything. Though aimed mostly at women as there are not a lot of calls for male corsets and they are actually constructed different conserning shape

-

nope ran out of lace lol and said to hell with it and moved onward did do two new laced belts though have to see if I can find pictures of them

-

Now I can get garment leather pretty easy around my place from tandy and another leather supplier (both are pretty good price wise) but I was thinking would bison make a good leather to use for a jacket? Or would would make a good outer covering for a leather jacket?

-

THanks Matt I am currenly looking at a hydraulic press as space is limited and I really do not want to put a 3 phase outet in the house lol

-

Talking in the 50 to 100 range high repeatability and the 50 to 100 a week

-

that may work as well due to space being a major issue may have to look into it

-

ohh I did not know that, and I have found a few clicker presses that are hydraulic and not electric.

-

I already use a knife and strap cutter I want something a little faster and something that has less chance of a slip up because with a strap cutter you can slip with one of those, not have the edge as straight as you thought or for any other reasons, blade is not as sharp and drags or pulls the wrong way...

-

Thanks looking into the price of a clicker press and Rockoboy I had thought of doing the whole laser cutting thing but as you said the scorching could be an issue and if I had to sand to much it would make it so the piece would not fit around the mason jar like I want them to sit down. So going to be looking into sizes and what not of clicker presses

-

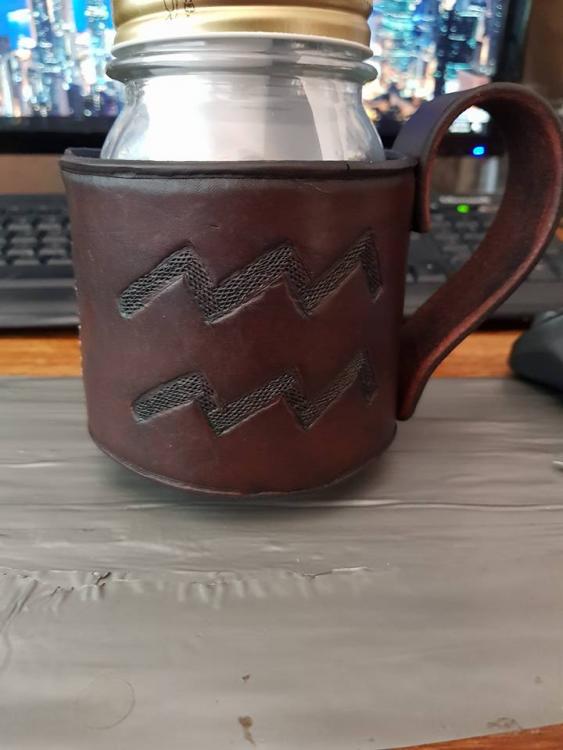

Have a business idea I am working on and i know if this takes off i will have to think about getting some machinery to help make things run a little smoother my question is what can make doung simple rectangles faster to mass cut out. I have found for 1 pint mason jar sleeves 3.5 inches wide by 11.75 inches long makes for the perfect tight fit (hand sewn baseball stitch style) so that will be the shape i will be cutting a lot of so what can i use to help cutting our blanks faster. Preferably something smallish as space is an issue

-

Fit is tight on the 6 oz, the 8 0z (as I am playing with thicknesses) is snug both hold really well Yep that is part of the line I am going to use that it can be used as a drinking cup or storage...recycle reuse kind of thing lol.

-

Two of three designs I have, thanks for all the help everyone. By the way the store idea that I am currently working on is selling the sleeves and mason jars, with a catch and that catch is I am actually going to be selling air...100% Australian ocean air, that is harvested by hand, just as the sleeves are handmade the air itself is harvested by hand...told you it was a crazy ass idea lol. I am sticking with the stitching to hold it together as I like that look a little better than straight rivets.