-

Posts

3,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

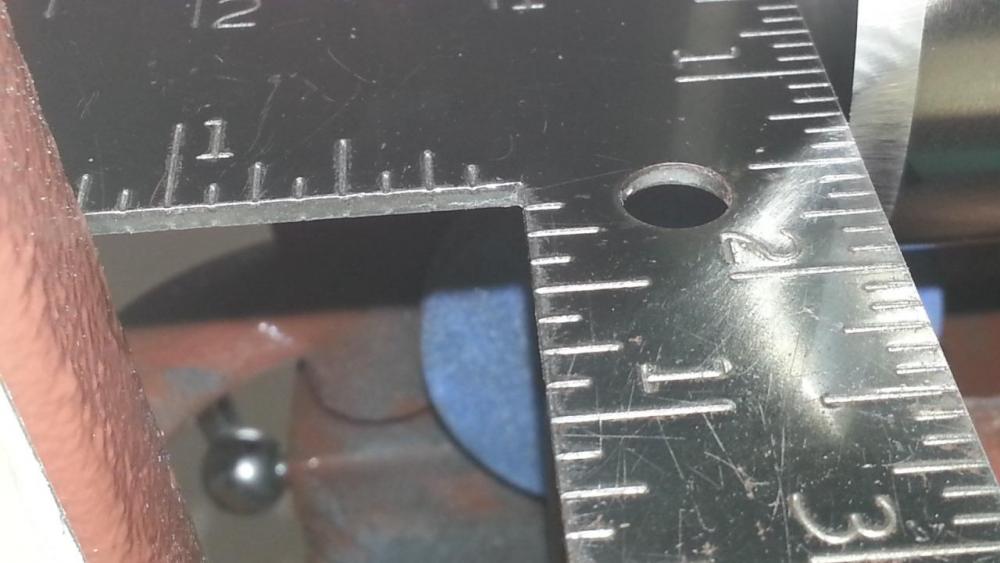

It is a framing square, the one side is 1," so if you read the inside dimension, you will have to add the 1," so yes, 2 1/4" total. The skiver does hinge back, I did that for the previous measurements. Not necessary for this one, I try to avoid it since I have to remove screws from the base to remove the drive belt to allow it to hinge (as far as I know), and one of them has already stripped out the wood. YinTx

-

-

I did run some leather through before I did the good leather, but I guess I should have asked for clarity. What characteristics would define a decent behaving leather? I should be able to get your dimensions later this evening. YinTx

-

There was a much older thread on LW showing this video. Judging by the "lines" on the skived section of my leather, my blade may still be a bit dull. Might be time to get a better stone for it. Anyone comment on the techniques used here?

-

Oh snap. I knew I missed one. Next time I'm there I'll see if I can get it. YinTx

-

@RockyAussie, here are some dimensions for you on the Cobra NP-4. Let me know if there is another you need... bottom opening side 1 bottom opening side 2 opening radius table thickness dimension from base of machine to bell bottom (note that divisions in this photo only are in 1/12's of an inch, not 1/8's or 1/16's) dimension of a "shop vac" hose YinTx

-

I'll try to get you some measurements if I can. It would seem to be a pretty simple thing to make it retractable? Would hate to have a spark fly into a pile of leather powder and set off a fire 2 hours later... Or perhaps a spark arrestor but I'd think it might be more difficult to implement. I had some success yesterday. First, here is the bad: leather goes through without skiving at all, then at the end, bites in and takes out a chunk. You can see where the blade went along without removing anything, then at the end, cuts in. So, I got to thinking sometimes it's the simple things that are the solution. This was simple: So, even though I had tried a couple of times already, I went at it again. This time I really dug in there with the ceramic rod on the inside of the bell to make sure I wasn't being too delicate in the past. Viola, all of a sudden it acted like a whole new machine! Here is the result, I was able to skive very fast, the feedwheel pulled the leather in without any assistance or needing to place it under the foot before lowering the foot. The only issue I have right now is where it takes a chunk out at the end when the skive overlaps. Do I need to reduce the feedwheel tension/pressure to alleviate this? YinTx

-

I'll try to get you some measurements if I can. It would seem to be a pretty simple thing to make it retractable? Would hate to have a spark fly into a pile of leather powder and set off a fire 2 hours later... Or perhaps a spark arrestor but I'd think it might be more difficult to implement. YinTx

-

If you are on that side of the pond, lucky you, Abbey England is nearby. Lots of hand sewing thread to be had from them, decent prices too. YinTx

-

Outstanding work! Impeccable tiny tooling. Welcome to the forum, look forward to seeing more of your work! YinTx

-

I'm beginning to think this is the best option. And that drawer is just there to cause jambs. And to make the mfr's feel like they did something to catch the leather for you. There just simply doesn't seem to be much out there, so anything that helps clear the mud or adds another way to do things can only help. I've seen one or two of your videos and had no problem understanding what you say, so just be fearless, yah? I haven't had time to mess with the thing this week, but have been trying to keep up with the info posted here, so thanks much to everyone participating, great info showing up so far! YinTx

-

Welcome! And be sure to share some of your works here, show it off or put it in the critique my work section, you are sure to get a lot of constructive feedback. YinTx

-

@jimi those are some fantastic photos. Some similarities and differences, at least I can see how the thing might be put together. Thanks for the links, definitely helpful. Took the video with an old Samsung SIII phone, and have a MacBook... barely compatible with each other lol. I'll fart around this week and see if I can get some of the videos I took today to upload... Yep, I have two of them already, don't want a third. Hoping I can get the other two functional with some simple parts, like a bushing, but the suppliers won't quote me a part. Going to have to have them made it looks like. The world we live in. YinTx

-

I'll do what I can, but in past I have not had luck uploading videos. Takes hours, and u-tube says too much data for a 3 minute video. I am not sure how folks upload 1.5 hours of 1080p video - they know something I don't! Better photos than I will get are above! Seems like this thread may be helping more folks than just myself.. Thank you all that are providing assistance! Yep, the 6 pager. Purty lame. yeah, I think I saw that video. Had the bell set way back too if I recall. I kinda trusted other videos more, didn't really follow anything from that one. You do. Lots of experience speaks volumes. I'm trying to listen and learn here.

-

Ed the "BearMan," thank you for gracing us with your presence and works again. I always enjoy studying your tooling to see where I can improve mine. It will take many many years of practice to get anywhere near your level. Just phenomenal. YinTx

-

I had seen this video, and pretty much followed it. Thanks for posting it, others may find it useful. I didn't have the issue he had with skipped sections, but the angle of the grind was off due to the bell being so far back initially. Mr. Bane was freaking me out feeding that leather through one handed with his fingers right above the bell business end. If that had bit into the leather there, he would have had red accents on the black. I keep my fingers clear of that thing at all costs. YinTx

-

yeah, I would have engineered it that way too. I know a company that makes metal wire scrapers, I may replace it with one. This one is frustrating. It pulls the pieces in right away as they are getting cut. Defeats the purpose a bit, I'd think. Probably better than trapping leather trimmings! But I'll try to get a photo later this week if I can. Kinda hard to get the phone up in there and all... I think so. I imagine it has a lot to do with the fact that the spinning bell lifts the leather towards the operator and thus the scraper, causing it to fall down. It seems to do it's job ok, the other scraper tho leaves a lot to be desired. I'll look closer, when I was looking at it last night I noted it was on a spring, but didn't seem to actually touch the stone. Perhaps it is somewhere that I can't really see, like the backside, closer to the operator. I don't hear any rubbing or anything while in operation tho...I'm just glad I am willing and able to troubleshoot this thing. Otherwise I'd be one unhappy camper! YinTx

-

Thanks @RockyAussie for more pointers, I've bookmarked the goods. However, perhaps the plot thickens. Here is what I came across this evening. I noted that the feedroller was constantly pulling up leather fuzz and feeding it to the bell, as I was running it with no leather. So I peered up underneath, and lo, jammed up under the feedroller was this nice little ball of skived leather. I worked it out, and it promptly trapped another. I am assuming this is not normal behavior. How do I remedy it? Do I need to just scrap this scraper? Entirely possible, I've tried to make sure there isn't one, but this bell thing is new to me and I'm learnin... I also have proof the good leather sensor is functional on this unit. Ran a lot of scrap in there, it skived beautifully, went to skive the good stuff, and viola, shredded. Picked up a piece of scrap without changing a thing, skived it perfectly. Sensor functioning. YinTx

-

How do I stop dye rub off/transfer from Horween Essex black leather?

YinTx replied to YinTx's topic in How Do I Do That?

I have no idea, but the back is inked "Horween" it was sold to me as Essex, and it rubs off everywhere. I did a small sample strip with Tankote, and the cotton pad with the Tankote turned black too. YinTx -

I have a side of black Horween Essex leather that I am working with, and I am finding that it is leaving black dye on my hands and such as I work with it. I am concerned it will transfer to clothes etc. if I use it for a customer. Anyone have this issue, and how do you remedy it? Will TanKote do the trick, or will it just streak and make the leather look plasticky? YinTx

-

Made a clutch

YinTx replied to DarrelT's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Pretty cool. What does the back look like? YinTx -

Motoko II backpack build

YinTx replied to koreric75's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I've seen a lot of round hole stitching going around, and wondered how well the patterns would look with standard chisel stitching. I must say you did it justice! Fantastic look. YinTx -

Awesome! I've tried three of these things and have failed each time, so kudos! YinTx

-

Yes, there is a scrap ejector. The plugging was clearly operator error, the jicky little bin under it was full and that stuff had no where to go but up. I removed the bin and let er fall to the floor. The ejector has a better chance of doing it's job for now... The first day I had it, the bell was about 1/2" back from the presser foot, and when I moved it forward, the stone beveled an angle that was no where near the cutting edge, so it had to get re-profiled. I tried to follow up with a really light touch, but it has always had that pattern on the bevel. I thought maybe that was the way it should be since I've never seen one up close until this one. I felt it was a bit harsh myself, but kinda didn't know for sure. Even the light touch with the stone leaves these marks. Do I need to find a different stone? It seems to grab on to whatever leather I am using like glue right away. I'll get a brass brush and see if it'll clean up.. but if it keeps up past performance, it'll get gummed up fast. Do I need to replace it with something that won't? my hunches confirmed again. I think this thing can be spun around for a less pointed approach, I'll give it a try. I'll give this a whirl. I can't wait to get this thing dialed in and my skill up on it, I think it'll open a whole new world for me... YinTx

-

I've noted that as well. In the case of the photo, it was all jammed up in there. Yep, vacuum excavator is next in the works I suppose. I had no idea. And I don't really know which one is set with more tension that which, so next time I get back to it I'll check for sure. I'll have to print out these tips and put them with the machine until I get em all memorized! YinTx