-

Posts

3,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

SOLD. Thank you! YinTx

-

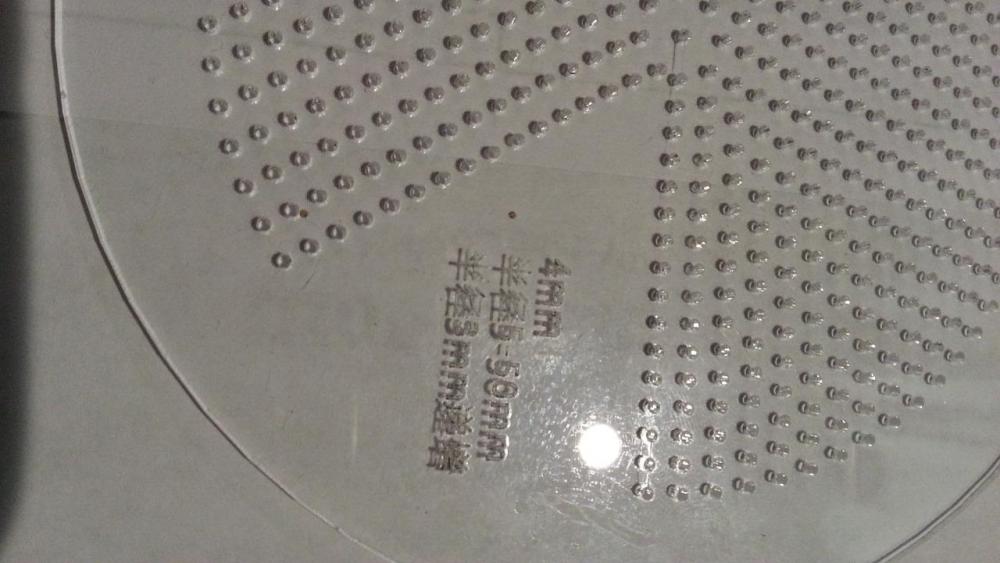

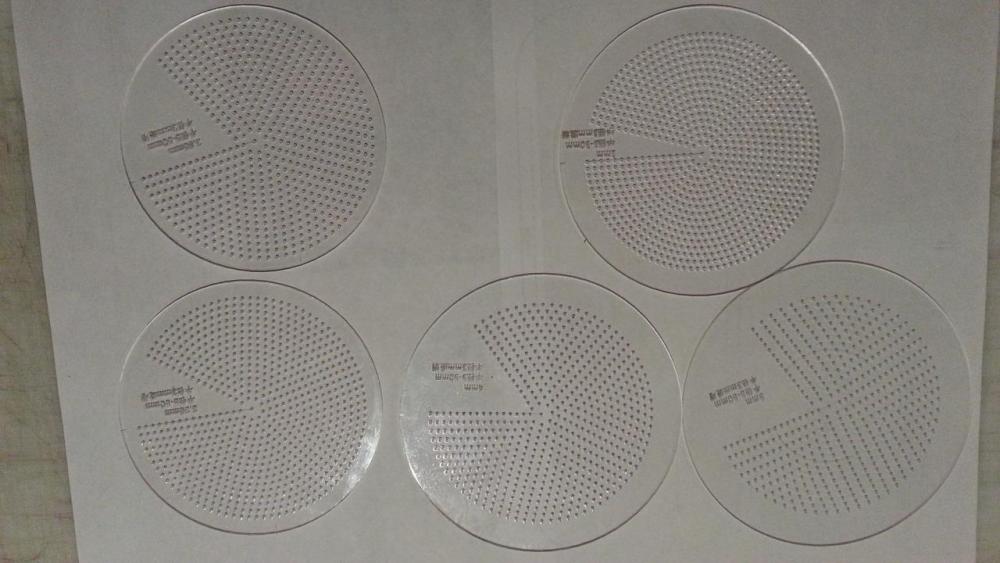

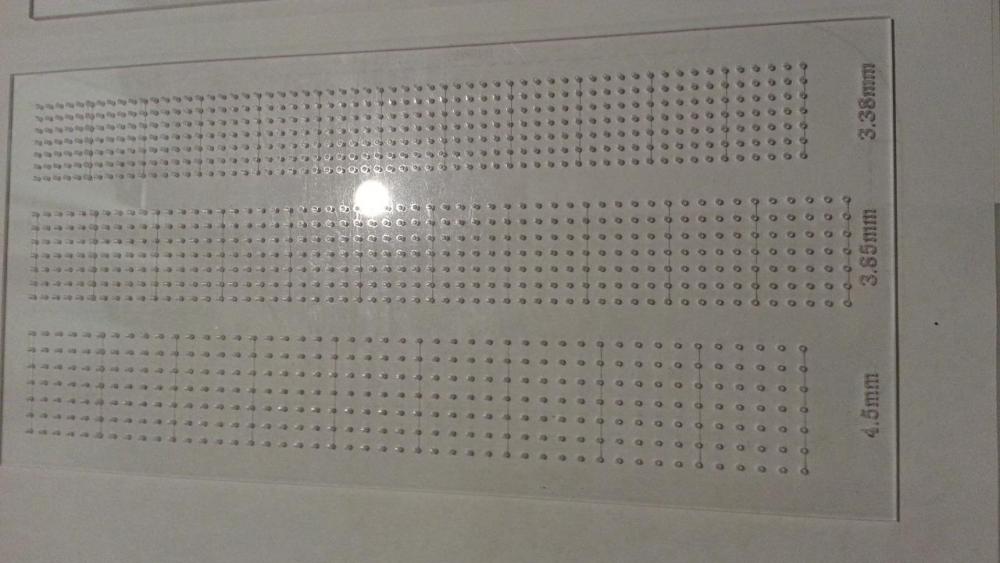

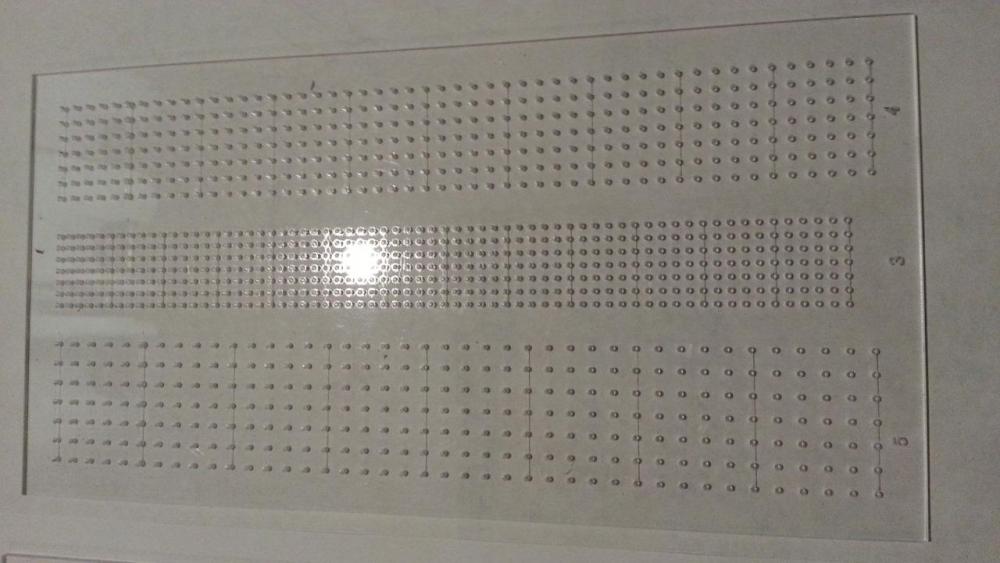

This is a complete set of circle templates and straight templates to mark stitch holes. They sell new for about $60, I will sell this set for $40 plus shipping. The circle templates are for 3mm, 4mm, 5mm, 3.38mm, and 3.85mm. The straight templaets are for 3mm, 3.38mm, 3.85mm, 4mm, 4.5mm and 5mm. YinTx

-

How to get your products to sell well

YinTx replied to RockyAussie's topic in Marketing and Advertising

This is where I am at. This is what I have discovered as well, along with some design changes that have helped sales some. So I've been on the fence as to whether I want to stay very small, or scale up and produce lower quality lower priced goods that will sell to more people. Thing is I can't help but still feel there is a crowd out there like myself that wants higher quality, greater craftsmanship, longer life out of their goods, and doesn't really care about that big brand name because they recognize it is mostly made in Asia anyhow, with crossed threads and popped stitches and shoddy edges, etc. I'm not sure there is a "distinctly American" leather good like there is a "distinctly Aussie crocodile." Maybe I haven't thought about it enough. So I am intently following both this conversation and the "How to make leather goods profitably" conversation. Thank you @RockyAussie for starting them both. YinTx -

Okay, now those are cool molds. Think you could 3D print a mold for me for a different purpose? Trying to make a case for a flip phone for my dad...how much would you charge? YinTx

-

Update: So I've had more success with the machine, following more diligent sharpening and a bit less aggressive deburring on the inside. I imagine it will only get better as I do things like put in a smoother sharpening stone, add vacuum, roller foot, practice, etc. Thank you all for helping me learn to use this thing better! Learned a really cool thing, and that is the type of foot you have installed affects the type of skive you get, beyond just adjusting the angle of the foot! Now I have to decide which feet to spend $$ on... Here is a photo of the recent skive, not perfect, but no holes blown out, and the thickness I wanted, on 5 oz veg tan even. YinTx

-

Awesome! Lots of folks here that can help with old machinery, and several tinkerers and restorers as well as leather folks, this'll fit right in! What do you plan to make? YinTx

-

Those are really cool! I've tried sketching up ball caps several times, they all ended up in the bin. I like the one you came up with, look forward to seeing your others. YinTx

-

Neat. I like that thread color on that dark brown leather, is it from Tiger? Would love to see a photo of the 3d printed mags.. YinTx

-

I'll PM you a link. It's Russian birch tar, so if anyone can read the label and clarify what it is? YinTx

-

First dopp kit

YinTx replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Huh first time I saw the photo, I thought they were contrast painted, and I liked it lol. Nice work, I like the tooled handle and the liner is a nice touch. YinTx -

Absolutely outstanding. A lot of hours must have gone into that! YinTx

-

@Otzi, I was mildly interested in trying some out, but can you clarify the price justification? It seems I can get a 10 oz bottle elsewhere for ~$26, 10 oz from you would be $350. It would seem if I was making products, this could make them even more expensive than they already are, and thus harder for me to sell. But is there something that makes one birch oil better than another? Thanks for the info, YinTx

-

Interesting stuff. Any samples of using it on leather, and how it should be applied? YinTx

-

My new bag

YinTx replied to bikermutt07's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Neat. I've left edges unpainted and unburnished before because I felt it matched the item that way, and have received a lot of static over it. I wouldn't change the items tho, so keep your artistic license despite the naysayers. YinTx -

Sold, Thank you! YinTx

-

Thats pretty awesome. Neat machines! YinTx

-

Thanks for your interest, PM replied. YinTx

-

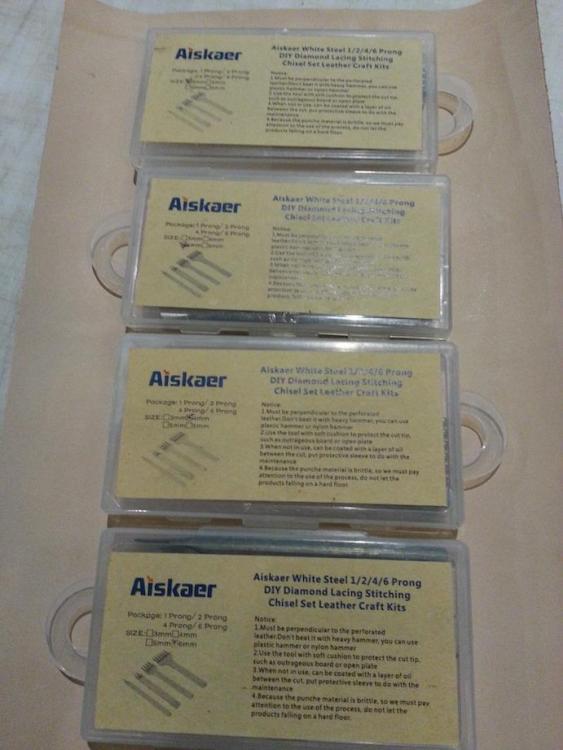

$45 plus shipping for the whole kit n kaboodle. All 20 of em. Like just over $2 per pricking iron. I thought it was, but they are still available! If they don't sell soon, I may keep the 10 tooth irons. Would be awesome for straps and belts! Here is a comparison photo vs. a Blanchard iron (which is not currently for sale...) so you can see the angle and spacing similarities: I'd venture to say the teeth on the Aiskaer irons are better polished than the ones on the Blanchard, which are a bit rough in my opinion. YinTx

-

Floral Belt

YinTx replied to LederRudi's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Belt is awesome, I'd change up the buckle and put in a loop myself. But very cool! YinTx -

I have complete sets of Aisker stitching chisels in sizes 3mm, 4mm, 5mm and 6mm. 1, 2, 4, 6 and 10 prongs on the 3mm size, there is a broken tooth on the 10 prong iron and a broken tooth on the 2 prong iron. 1, 2, 4 and 6 tooth in the 4mm size. 1, 2, 4 and 6 tooth in the 5mm size. 1, 2, 4 and 6 tooth in the 6mm size. There is also a set of unmarked but matching 10 prong irons in 4mm, 5mm and 6mm. Asking $45 plus shipping, which is 50% of new price. YinTx

-

Luggage Tag

YinTx replied to Sperrier's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

+1 and cool tag! YinTx -

Bah. Tried sharpening again, stropping, it's worse. Worked better yesterday. I wouldn't think there would be skill in applying a stone on these things, but apparently there is. Will order a smoother stone Monday. YinTx