-

Posts

4,854 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

Juki LU-563 - reverse stitch keeps breaking needles

dikman replied to Thatone's topic in Leather Sewing Machines

Strange. The only way I can think of for a needle to break like that is if the hook is catching it (I've actually done that, before I understood how to properly adjust things). All my other breakages have been on the downstroke due to needle deflection and hitting the feed dog. -

Must be something in the water over there then..... R8R, even though my instructions don't show them, I can cycle through and see the same settings that yours has. The rear connectors are the same, other than the 2-pin on mine is set for an LED. I've got it working but found that to get the slow speed control I want I have to set the max speed low, about 800. Above that it takes off pretty suddenly and doesn't seem to have the slow ramping that my others have. It's rated at 550w (who knows what it actually is) but appears to have plenty of grunt, doesn't have any trouble stitching through 1/2" of veg with #138/size 140 needle.

-

That is beautiful (and quite elegant)! That stamping must have taken a while.

-

Ahh, that makes sense. One question solved.Thanks mate.

-

I've no doubt that the sp-1100 is a good motor, but 1 1/2 hp seems a bit of overkill on the Consew.

-

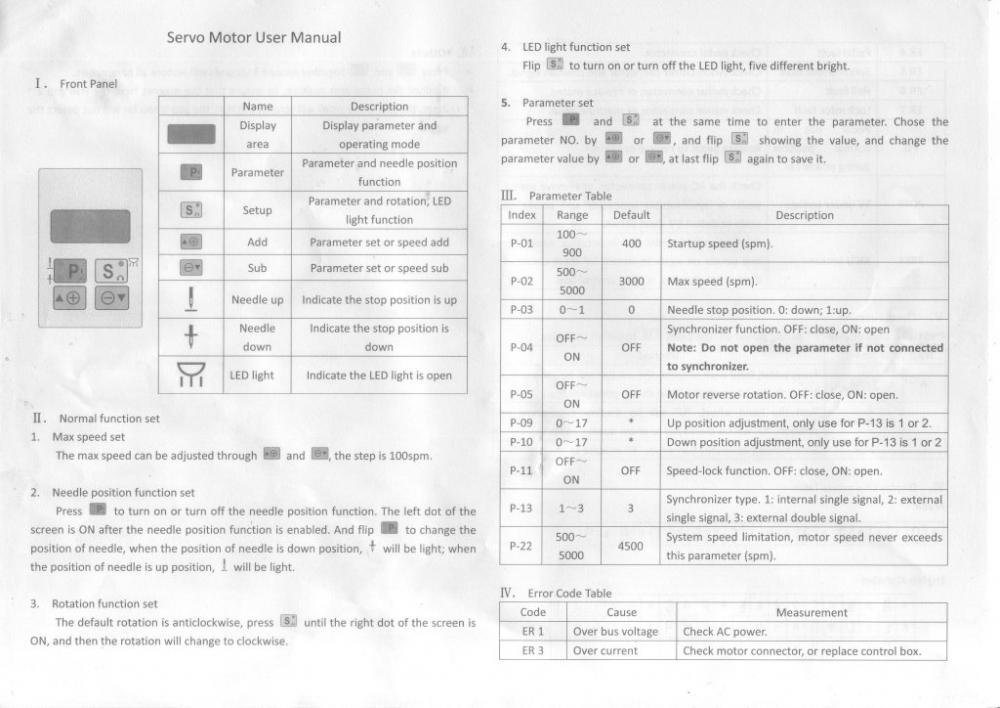

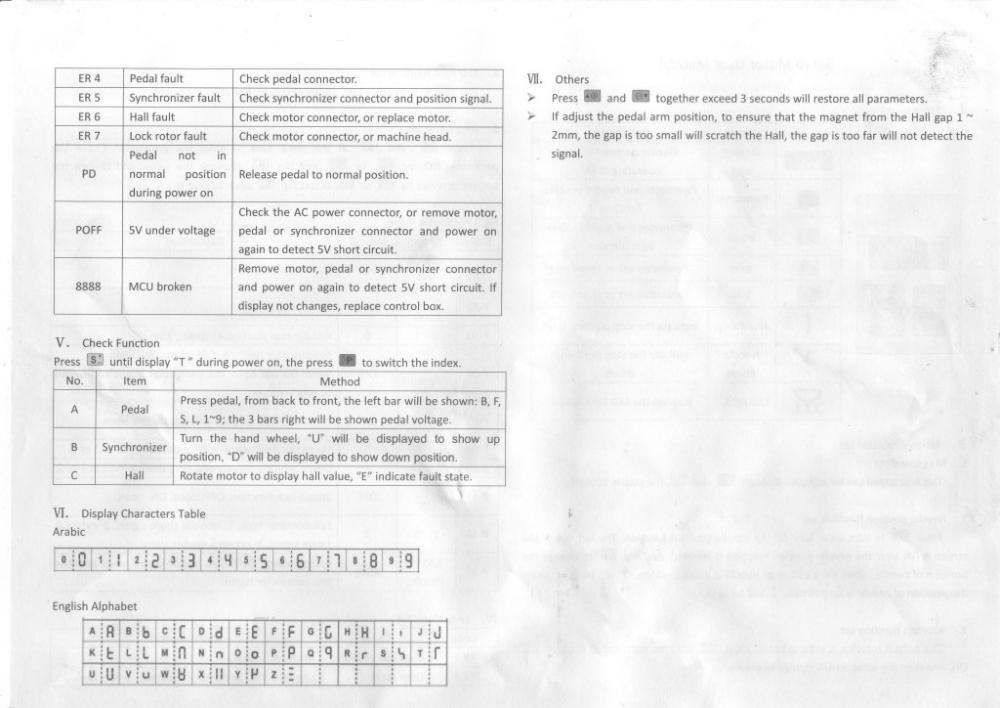

Very interesting. There are definite similarities. Although my instructions stop at 22, I think it continues to step past there so I'll have to do a bit of experimenting. P11, speed lock, has me intrigued (?). This seems to add credence to the idea that many of them may use the same circuit board and just disable the features not needed. Mine doesn't have any markings to indicate brand so it's presumably just a generic unit supplied to various companies, the build quality, while ok, is definitely not up the the standard of my other servos (made by Lishui).

-

My servo arrived unexpectedly this morning (the tracking still showed it in transit "somewhere"!). I was concentrating working on a trigger in the shed when he came in, gave me a helluva fright!! Anyhow, for what it's worth these are the "instructions" that came with mine. Looks like I can reverse the motor just by pushing one button (dumb idea!) and turn a LED on /off. I'll have to see what sort of voltage that connector is putting out. They must use gorillas on their production line judging by how tight the mounting screws were!!

-

Pfaff 335 17b h2L stitch problems

dikman replied to libbysstitches's topic in Leather Sewing Machines

Sounds like you found someone to fix it who knows what they're doing.- 18 replies

-

- pfaff 335b

- stitch length

-

(and 1 more)

Tagged with:

-

Man, the planets really aligned for you!! That is a good buy, as JLS said should handle up to #138 thread/23 needle. For what you paid for the Rex I'd keep it (if you've got the room). Now just try and stop looking for bargains!

-

My latest servo (overdue delivery but hopefully any day now) has a 4-button control unit. It's a long shot, but I'll try and see if there's any correlation to yours.

-

I found, much to my annoyance, that many of the options/settings on my two-button servo were disabled. No idea why.

-

Not really big enough, in my opinion, particularly if you're going to try and get a clutch motor to crawl. I tried various combinations of speed reduction, using a clutch motor, when I got my first machine but I could not get it to go slow enough (or control it!). So I bought a servo and made a speed reducer - much better. I didn't hesitate when I bought a couple more machines and ordered servos straight away. By all means try it with the clutch motor, but don't expect to to be able to sew stitch-by-stitch.

-

First Holster...

dikman replied to ewayne53's topic in Gun Holsters, Rifle Slings and Knife Sheathes

By George, I think he's got it! Looks good. -

Those "crucial parts" aren't necessary to run the machine, they're simply there to meet the manufacturer's legal safety obligations. Unless you're really concerned (or paranoid about safety) I wouldn't worry about them. Maybe you could try a rag dampened with WD40 to clean it? Personally, I'd try and clean as much from the bobbin case as possible without dismantling it - unless you're very mechanically minded and know what you're doing! As for the feet, you could grind them flat or try filling the grooves with JBWeld. Kwok Hing is one supplier of feet for some Pfaff machines. Sewing speed, perhaps consider fitting a speed reducer?

-

My suggestion is to try it first with the stock handwheel/pulley. If you find it's not slow enough then either fit a speed reducer (commercial or make your own) or a 7"-8" pulley on the head. The main thing is to measure the shaft and find one to match that diameter, usually 1/2" but measure it with a set of calipers to be sure.

-

Great deal for $50!!!! That servo should be fine, but if you want to go real slow you'll need to fit a speed reducer of some sort. The servo probably has a 3" pulley so replace that with a 2". Best thing to do is try it first with the servo and see if it works ok for you. Belt size, that will probably be a bit of trial and error to get the right size. I set mine up and then wrapped a piece of rope around the pulleys and tied it off with cable ties, this gave me a pretty good idea of what size I needed. I'm not familiar with the machine but I would say it's designed to use #69 thread with a size 16 or 18 needle. It may handle #138 thread, which will need size 22/23 needle. I'm sure someone will join in who knows more about the machine. Oil. Normally you'd only put a drop or two down those holes every few hours of use, but you'll need to check the machine and see if there's any oil on the moving parts first. Depending what was used before it could be a bit gummed up.

-

Actually, they will work in leather (although if it's too thick or hard they may stick coming out!) and should work in lighter garment leather, but in general you'll want leather point needles, particularly for veg tan. It's always handy to have an assortment of needle types though, just in case.

-

Search the site for "speed reducers", basically a pulley system to slow things down (and increases torque). You can build your own if you're mechanically inclined or there are a couple of styles sold by vendors who advertise on this site. There is another option and that is to replace the pulley on the head with a larger one (7" or 8" is probably the optimal).

-

Juki LU-563 - reverse stitch keeps breaking needles

dikman replied to Thatone's topic in Leather Sewing Machines

Did you say it's breaking on the upstroke??? -

Finally finished a new cross draw holster

dikman replied to 3248tm's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That looks very nice. -

Thanks plinker, obviously not a clutch motor then.

-

Yeah, ok, I sort of asked for that I guess. I was referring to the apparently peculiar way it appears to be connected......where, for example, is the speed control? It has me intrigued.