-

Posts

4,828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

cobra sewing machine Cobra C3 - Thread options?

dikman replied to entropie's topic in Leather Sewing Machines

Wiz, I'd say that I've got a greater chance of winning the Lotto than finding something like that here in Oz!- 13 replies

-

- braided plyester

- nylon thread

- (and 7 more)

-

cobra sewing machine Cobra C3 - Thread options?

dikman replied to entropie's topic in Leather Sewing Machines

Yeah, it just bugs me that I can only use this thread for handstitching.- 13 replies

-

- braided plyester

- nylon thread

- (and 7 more)

-

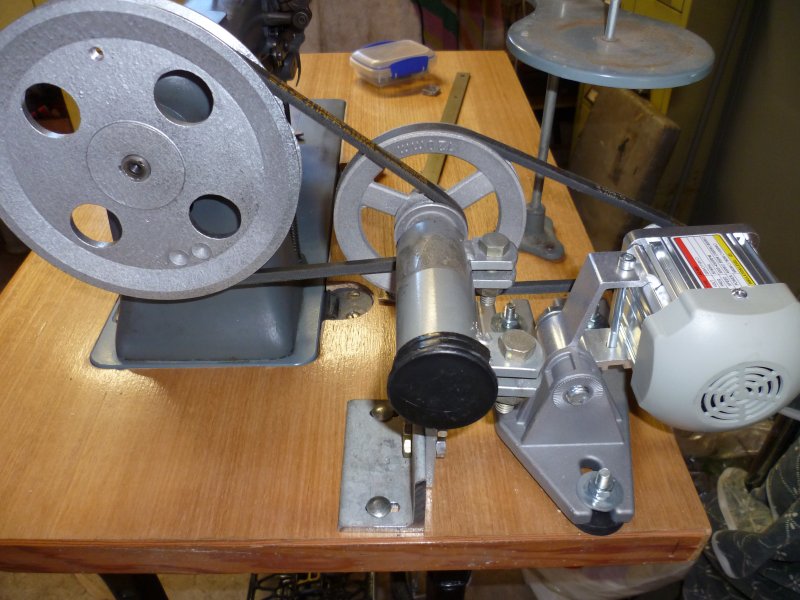

On to Version 3. While it would turn over at fairly low speed it didn't matter how I played with the settings the transition from slow to fast (whatever I'd set the max to) was just to quick for my liking. So the only answer was to resurrect one of my reducers and modify it fit this setup. Fortunately I had a few short belts that would work and a goodly assortment of pulleys. It actually works quite well now. From the motor to the reducer gives me a 2.7:1 reduction and from the reducer to the head another 3.9:1. I can now sew at 1 stitch/2.5 secs and changing the max speed is simple, two buttons on the front of the control box if I need a faster top speed. Wonder what I can do next?

-

cobra sewing machine Cobra C3 - Thread options?

dikman replied to entropie's topic in Leather Sewing Machines

My experiences with using wax (beeswax, tallow, candle wax) in shooting and reloading is that once you get wax on something it's almost impossible to remove it completely! So while I'll happily use it to buff leather and seal the edges it isn't going anywhere near my needles!! I'll stick to "conventional" thread.- 13 replies

-

- braided plyester

- nylon thread

- (and 7 more)

-

cobra sewing machine Cobra C3 - Thread options?

dikman replied to entropie's topic in Leather Sewing Machines

Matt, it's dry. Maybe it has to be run through a wax or silicone bath while sewing? Too messy to try and I definitely don't want wax gumming things up.- 13 replies

-

- braided plyester

- nylon thread

- (and 7 more)

-

cobra sewing machine Cobra C3 - Thread options?

dikman replied to entropie's topic in Leather Sewing Machines

For what it's worth - I have some braided polyester thread (#69) that came from a closing down boot factory. It's beautiful thread, but so far I haven't been able to use it successfully in any of my machines (an assortment of medium-weight upholstery machines). At some point the hook inevitably catches in the braid and I don't know why. I've no idea what machines used it in the factory. By the way, you're not the first person to want to use their hand-stitching thread in a machine and thus far I'm not aware of anyone who has. Maybe you'll be the first?- 13 replies

-

- braided plyester

- nylon thread

- (and 7 more)

-

You have a way with words, Wiz. My latest servo doesn't have the smooth (slow) transition from start to max movement that my others have (different brand). I figure it's probably due to the design in the way it interprets the signal from the Hall Effect sensor, so not much I can do about it (other than mess around with additional pulley reducers). When you try a different brand it's pot luck whether it will perform how you would like it to.

-

I keep 1/2 dozen spools with the 117 and as they are kept in a small container they keep unwinding! I looked on Thingiverse and found three types of bobbin clip, this one seems the best. Fits Singer 111/211 type bobbins, but will stretch a little to fit some others. They stand upright and I can write the thread size on the clip (so I don't get confused). They work fine in PLA but a springier filament would probably be better (nylon?). Improved_Sewing_Bobbin_Clip.zip

-

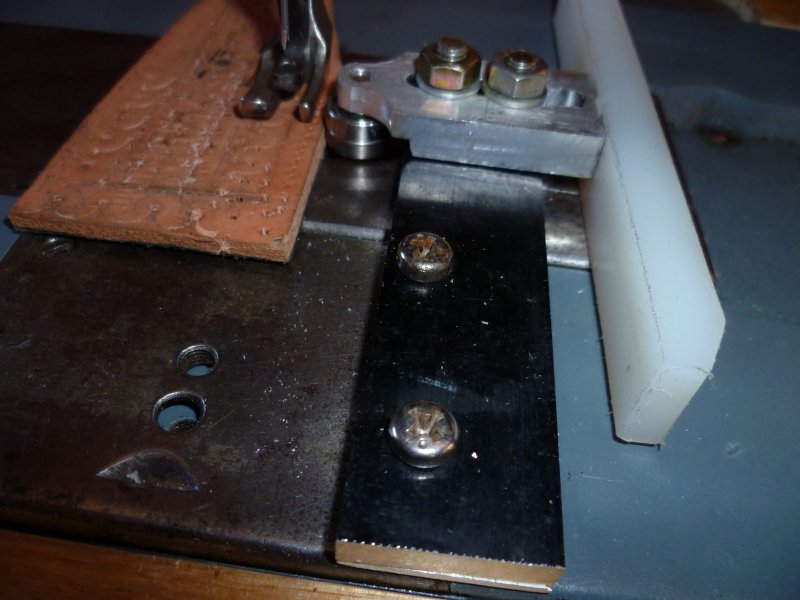

Now that my 111W117 is functional I figured I'd need a guide of some sort for belts etc. As the front plate has a few screw holes already in it (for who-knows-what accessories) I decided it would make sense to use them. I eventually worked out that they were tapped Metric, most surprising for a machine made in the US probably decades ago. This is the result, bearings from a junked hard disc drive, long guide machined from a piece of round hard nylon and assorted scrap. Hopefully it should work.

-

oops I did it again as the song goes - Singer 29Kxx

dikman replied to plinkercases's topic in Leather Sewing Machines

Nice one! Trouble is it's pretty hard to stop when a bargain comes along. -

Pfaff 138-6 Looking for price and parts help

dikman replied to Scoutmom103's topic in Leather Sewing Machines

I'm with R8R. If you must pay something $5 and salvage whatever parts you can (screws etc). That is bad. -

What a load of garbage!! Whoever you spoke to has no idea what they're talking about.

-

What should I look for on a used Juki LU-563?

dikman replied to LederMaschinist's topic in Leather Sewing Machines

If it's the original owner then I think you're off to a good start. I can't add much other than agree that turning it over by hand, listening and feeling for anything that doesn't seem right and checking that it stitches is a good idea. -

**NEED HELP** Consew Con-Serv E6 error

dikman replied to DS STRAPS's topic in Leather Sewing Machines

Do you have any paperwork for the servo? It should show you how to change a setting to turn off the positioner, unless you actually want to use it in which case yes, you have to plug it in.. -

I've made this post as a link to a previous post about 3D printing pulleys (took me a while to find it last time I went looking).

-

If you definitely need the binder then I guess the 335 is the logical choice, but other than the binder the 227 is the superior machine for leatherwork, in my opinion. It also handles heavier thread.

-

Cowboy 3200 foot impressions.....help needed

dikman replied to kyleatherworker's topic in Leather Sewing Machines

Best thing to do is try it. If it doesn't work just move it back. -

Looking for help in identifying this Singer

dikman replied to STARSTITCHED's topic in Leather Sewing Machines

Except for W and SV models. -

If you've got the clearance then try shimming under where the foot attaches to the main bar (under the two screws). As long as it doesn't scrape on anything it should be fine. It's the same attachment method as the Pfaff 335 and there's no vertical adjustment.

-

It should go under that check spring (wire loop),

-

Welcome to the forum. It's good that you've given yourself some time to work out what you need. Unfortunately (for you) R8R is right and you'll likely be looking at two machines, given the probable range of materials you want to cover. Saddles are the killer, as, like holsters, you'll probably need something like a 441-type machine. As Wiz has pointed out elsewhere, they can be "dumbed down" to handle lighter stuff but then you'll be spending time readjusting settings when you change material. For the "lighter" stuff probably a medium weight upholstery-type machine - Consew 206 or the newer Consew 1206, for example. Is learning to handstitch the saddles an option? Might be slower but handstitching will give a stronger finish and save buying one machine? Just saw your post, no, you can buy a new 1206 cheaper.

-

Well done, councilman! Sounds like a real good deal to me. I had the same problem (still have, actually) regarding lack of room. My solution - dismantled my glasshouse, sold it (got more than I paid for it ) and built a small shed in place of it for the sewing machines. Unfortunately, I ran out of room again and now have one in my garage. As for the WSV77, after comparing parts in mine to the 111W15x manuals the best I can figure out is that it appears to be the same as a 111W153. It's definitely not a W155, but I'll be interested in your thoughts after comparing it to the W151.

-

That should work. The other option is to drill and tap that other one for a second screw, which I've done on a couple of pulleys. I've run a smaller belt like that and so far it's been fine. There is a possibility that it may slip, depending on the fit in the pulley, but so far it hasn't been an issue for me. The alternative is to fit a larger belt, which will then ride a bit higher on the motor pulley but will still work. The only potential issue with a wider belt is that it may be be a bit stiffer. I've done both. This is one I've just finished - As you can see the belt is low in the pulley, but it has driven a size 24 needle through 1/2" of veg without slipping/stalling.

-

Fitted my (cheap) servo and I must say it works well. I have to set the max speed fairly low otherwise it takes off too quickly for my needs, but it has plenty of grunt. My Organ leatherpoint needles also arrived today, and using the knee lift I can just shove 1/2" of veg under the feet and it handles it easily (#138 thread/size 24 needle). I wanted to use the original Singer pedal ('cos it looks cool) but there were a couple of problems. It was too high to comfortably use the knee lift so I made some brackets and lowered the supporting bar, and because the pivot points are behind the balance point the pedal had a lot of forward weight so I used a piece of elastic strap to take some of the weight. Seems to work ok. I had to open out the hole in the feed dog as there wasn't enough adjustment to centre the needle properly (the 117 doesn't have all the adjustments of the later 111W15x series). I had to make a couple of attempts at this as it was cutting the top thread on the upstroke! A bit more care and lots of polishing fixed that. Next problem was the knot was sitting on the bottom of the leather, I couldn't get enough top tension to pull it up. Replacing the beehive spring on the tensioner with a stiffer spring fixed that (I've no idea where the spare spring came from, but it fitted). I'll leave this set up purely for #138 thread, although I wouldn't be surprised if it could handle #207. Maybe later....

-

Juki LU-563 - reverse stitch keeps breaking needles

dikman replied to Thatone's topic in Leather Sewing Machines

Strange. The only way I can think of for a needle to break like that is if the hook is catching it (I've actually done that, before I understood how to properly adjust things). All my other breakages have been on the downstroke due to needle deflection and hitting the feed dog.