-

Posts

5,999 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

What projects can I do with 5/6 oz leather?

fredk replied to BigLeatherVic's topic in Leatherwork Conversation

Its an ideal thickness for making ladies over-shoulder carry handbags -

My preferred method is to wet the leather, not too much but thoroughly, then apply multiple coats of thinned dye

-

I would think that is a water-slide decal/transfer

-

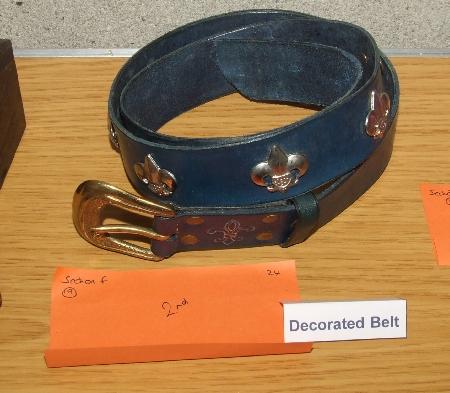

btw, that belt that took 3rd place. I made that for a guy in my medieval group. He insisted he was a 38 inch waist, his mum agreed, so I made it for 40 inches. Turned out he was a 46/47 inch waist. His old shop bought belt and trousers had the vanity marking of 38 on them. I measured his old belt to his well used buckle hole and it was 45 inches. I made him a larger belt, and made him pay more. So that belt has been in my 'stock' since about '14

-

Thank you, Turning a mistake to an advantage I have a small brass maker's stamp, about 30mm across and 18mm high When pressing this mark into very thin leather, say 1.2mm and less, (under 3oz) I have to be very careful on setting the height on my press otherwise the stamp cuts through the leather, like a clicker cutter. I've turned this problem to an advantage. By adjusting the height on my press I can just cut through the leather. But not 100% cleanly, I leave it so I have to pull the leather way from the oval. Why? Because those last few fibres hold the centres of the A and D in place. I'll sort this out by using my mini-drill and a grinder to lessen the height of all the letters so they don't cut through. By cutting out the oval I can get tags out of scrap pieces, which I can glue inside drawstring bags made of chrome-tan and that sort of thing eg Yesterday evening I started sorting out some boxes of small scraps and ended up punching out over 50 tags. Once started it was quite addictive, to see if I could yet another one out of a small waste piece

-

I too have a piece of leather that looks a bit like that on the rear. But do the burn test to check

-

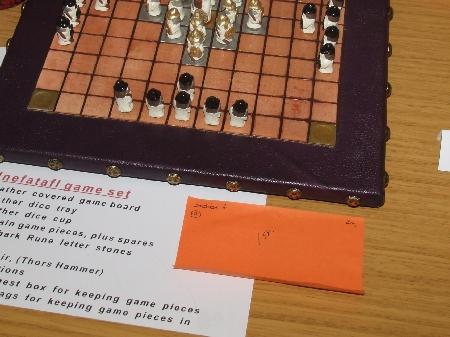

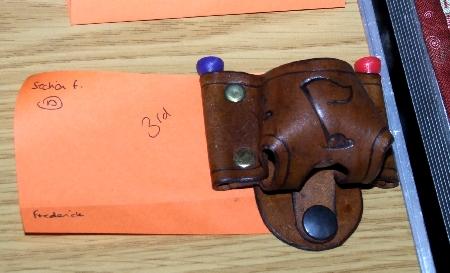

On Wednesday just past I happened to be in my local Community Hall and I found out by accident that there was to be a show for local home crafts this Saturday (today) Entry fee of 50p per item. As many items as you want to exhibit. To be in place on Friday between 5 and 8 pm on Friday I sorted out 12 items, finding that some items I would have liked to show are with my 2 agents. I also made a couple of things, such as the dice cup There were different classes for different crafts but not one for leather so the organisers put my things into a very general section covering many crafts What I displayed; from left to right and from back to front; (the wood fairy door is not mine) Leather chess board (with a few pieces), Knitting belt, Hnefatafl game set, a decorated belt, a small valet tray, a key-ring coin purse, a small draw-string bag, a 1/2 moon coin purse, a wrist purse, a hat, a golf ball caddy and a notebook cover Judging was on Saturday morning. The judges decided to divide the main Class into sub-classes I got 1st, 2nd & 3rd place in the sub-class and 1st overall in the main Class The Hnefatafl game set took 1st The decorated belt, which is actually not that great and was just put in to bulk up numbers, got 2nd place And a Golf Ball Caddy, from a Tandy pattern, got 3rd place. Apparently there was a lot of interest in this, no-one having seen one before I know the judges had lifted and studied most of the items as I had left them in a certain way and most of them had been put back differently. At some events the judges just have a basic look at items. My prize is a £20 voucher card for a local craft shop.

-

Even ammo needs sorting out. One duty I got in the RAF once was to help sort out the ammo. 3-oh-3 et cetera bullets had to be put through a special gauge to make sure they were made accurately, About 60 -70% were, the rest was outside tolerances. Allegedly the bad ones were sent off to the Army,

-

A wee tip. What you are trying to make is just a refillable spray can. Something I learnt to do with regular ones; keep them very warm just before and during use. Very warm but not hot. Stand it in a jug of very warm water until the can itself is very warm. If the session is long return it to the jug of water. This increases the air pressure but as long as the can is very warm the pressure will stay high. You can do this with any aerosol can. It helps to get the very last of the contents sprayed out

-

Without seeing the back side, I think they are brass Saddlers Rivets https://www.tandyleather.world/products/rivets-burrs?_pos=3&_sid=201fe85b4&_ss=r

-

Thats excellent A good source for these sort of parts and buckles too is 'Thrift stores (known as Charity shops in UK). You buy their cheap 2nd hand goods, you get cheap parts and they get more funds $10 for a couple of magnetic closers?!?. I get. literally, 10 for £8. Just bought some recently for that price. Shop around friend

-

Its not really. In the 35 years I've had it I think I've used it no more than 3 times. The air pressure goes down very quickly, after only about less than a minute of spraying then you need to use a compressor to recharge it, so you / I might just use a regular spray brush running off the compressor

-

I got that for about 1 minute earlier this morning. I also got on other forums. Odd thing was two pages/tabs on one forum wouldn't connect but a third page/tab on that same forum ran normally

-

I know you're having fun but an easier solution is an ordinary home mist sprayer; the type sold for spraying water on to plants, or spraying cleaner on windows. I used one to spray diluted Resolene on some things And I found my Jenni Can and got it cleaned up. I think it might still work Air in valve on left, release valve on right. The top unscrews for putting the fluid in. It takes a range of different changeable spray heads

-

Looks very nice so it does Have you a cork stopper for it?

-

Ask Le Prevo if they have any in stock

-

I started to make another dice cup today. I'm making it the same way. I cut my piece from a different hide but of the same thickness. I cut it to size with the flesh side out. Then I turned it around. A very slight gap, maybe, its under 1mm, maybe as little as under 0.5mm. Close enough to be the same size

-

Two ways I've done a transfer 1. print out normal. case the veg tan. lay the printout on top of the leather and using a ball-point modelling tool go over the design, press hard and the leather will take the impression 2. put design on top of dry leather but with a piece of carbon copy paper in between. use the ball point modelling tool and the design will transfer

-

-

A thought; get a spray can which has a rotatable nozzle. On some cans the nozzle where the paint comes out can be rotated through 90 degrees. Thus you can get a thin tall spray or a thin wide spray. Sometimes the nozzle head with this can be taken off one can and put on another

-

That little shield you use when removing your stitching chisel ...

fredk replied to OldCanuck's topic in Leather Tools

This subject came up in another thread but I can't find it right now I made one if these thingies out of a scrap piece of clear acrylic -

I have a thing called a 'Jenni can'. Its basically the same. Recommended PSI is about 50 max. Its many years since I used it. I found it recently, then misplaced it again afair the valve on the Jennie is all metal and screwed into the bottle

-

There are about 6 or 8 different airbrush to hose fittings. I suggest you contact this model shop. He may be able to fix you up with the correct fittings or adapter. He has an excellent reputation here in the UK but he's down your way https://www.ebay.co.uk/str/amodelerclub

-

The compressor should never get that hot Is it an 'oil less' one or is there an oil filling plug on it?