-

Posts

5,974 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

btw, with using all these different solutions on your leather they take out its natural oils which makes the leather go as stiff as a piece of masonite. You'll need to give it a feed of neatsfoot oil, aka NFO. But go easy with that, too much and its ruined. To make sure I give just a small amount of NFO, I have a wax & NFO mix which I apply and rub in, then buff off.

-

Fiebing's Deglazer is very expensive for what it is. I can't remember just what it is actually made of but I use cellulose thinners, aka lacquer thinners. Costs me under £10 for 5 litres NFO in the dye doesn't really help prevent blotchiness. It helps a wee bit. Wetting the leather first helps more

-

NFO wont help now

-

Work it over so the splotchiness is more even. Then it becomes 'artistic' !

-

meabee I got included automatically so I don't need no 'green bar' like you lesser minions do,

-

IPA, vodka, beer, . . . . but not wine, unless you want it red + 1 on the dipping to dye

-

An extreme measure; mix up a big basin of water with lots of alcohol in it. Dunk your piece in it for a while. Agitate every so often. You should see the dye staining the water after a while. When the water is quite yellow, change it for a fresh mix. After a few goes of this there will be less dye in the water. Lay your piece out to dry naturally. It should/might dry out with a more even yellow tint to it or start again. wet your leather before dyeing, this helps with the distribution of the dye through the leather

-

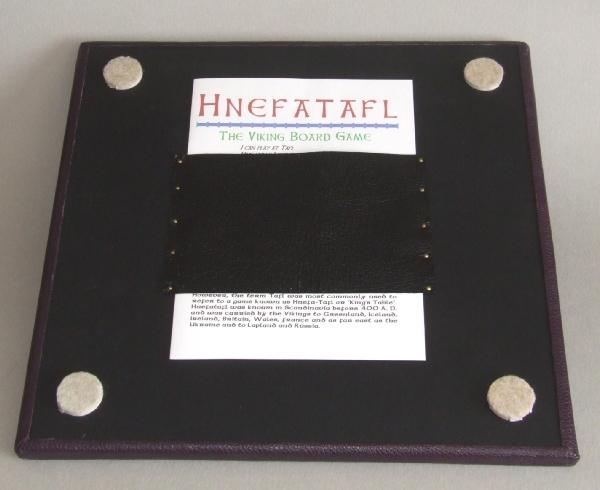

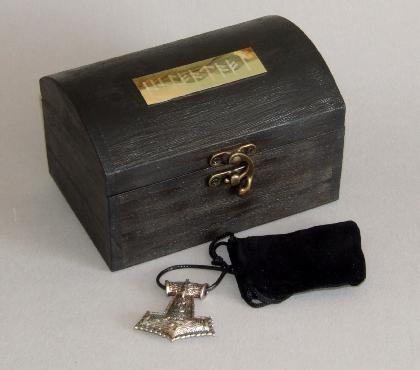

Finally finished this game set for #1 favourite dottir Not that it took me very long but I meant to give it to her for last Christmas! She's coming over for a visit next week so I thought I'd better finish it! The Board; MDF covered with a purple coloured chrome tan and the playing area is veg tan, stamped and lines gouged, and then glued onto the board The box and its contents; The dice tray, which has her shortened name on it in Elder Futhark Runes And the dice cup. Veg tan leather, flesh side out and a piece of embossed 'snake' (?) skin leather glued on the outside Now to finish my own set

-

I had a 'green bar' flash up yesterday evening, for about 2 seconds. I haven't seen it again. We have 'green' bars and 'orange' bars here. As I'm colour-blind I just drink at home

-

and now it will be very jealous looks as others fill their cars petrol tanks! sorry, I forgot my manners. That is just grand work on that harness and, you know goats will eat anything? When I kept a few goats, they'd eat nylon ropes, chew on metal chain but they would not eat leather straps

-

They are all quite similar, but the top makes use ball bearing races to make the swivel smooth whilst the cheaper ones just rely on the yoke turning in a drilled hole. If you buy one of these; first, dismantle it and put some toothpaste into that hole. re-assemble and work the yoke turning in the hole. the toothpaste will smooth the action. dismantle, clean out the toothpaste and apply a light coat of 3-in-1 oil

-

There are still parts of Europe where in rural areas people use goats, dogs and even pigs for pulling small carts. Carts big enough to carry produce to the local market or to take children to school. These are still used in rural US more of an old tradition rather than for need I can't find a modern image of a pig-cart but I do know they are still used, mainly eastern France, western Germany, lower Netherlands and south-west Belgium

-

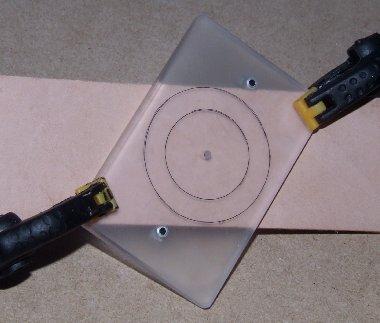

I use this; Two pegs, you see them top and bottom, the black dots, and a hole centred between them. Put the pegs against the sides of the strap and the centre hole will always give the centre of the strap, no matter what size width the strap is. The circular lines help with spacing; put the line over the previous centre hole and the new holes will be evenly spaced out

-

If the punch is sharp, all good advice above, but the plugs still get stuck, I use a pipe* lighter to heat the end of the punch up. The leather cooks and shrivels and can then just be tapped out * pipe lighter, like a cigarette/cigar lighter but the flame comes out at an angle to the side and they are a bit more like a mini blow lamp

-

or for making a swage in sheet metal work

-

mmm, interesting. I never even thought of that. That might be a whole new market. We have several extremely large engineering companies here, The welders usually wear large leather gauntlet type gloves with a gauntlet cuff that goes up to their elbow

-

Nice work, especially on the 'Dragon Scales'. Anything like that is not easy to keep aligned. I think I saw these, or something like them. before as I then went and bought the 'Dragon Scale' stamp Not much difference between 'Cowboy Cuffs' and Archery Bracers The only difference I would do is make those straps of a thinner leather and skive both ends of them as well

-

I think a couple of youse are way out of order Its against the ethos of this forum to condemn anyone on the basis of their standard of work; From raw beginner, to the top professional, through folk who just want to cobble some thing together, if they enjoy making anything in leather no matter what their standard is they are welcome here. Some folk get better with practice, some don't. In the end if you enjoy leather working or crafting then you should be allowed on this forum Crap?

-

If you browse without logging in you don't see the special off-topic threads, just the regular stuff

-

A pouch for my daughter

fredk replied to Brokenolmarine's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Excellent. But you do know that is not a 'suggestion' but an indirect command to you to make one ?