-

Posts

5,248 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

New Shoulder Holster

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks, Double Daddy, . . . it's a compilation of several different designs, . . . took some of my ideas, . . . added some others to them, . . . made this for a local guy who really loves his little SP101. I'm a 1911 guy, . . . I was real happy the way it all turned out. May God bless, Dwight -

Too Critical or not critical enough?

Dwight replied to Boriqua's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Actually, . . . Electrathon has the "professional" view, . . . and it is a good one, . . . no questions asked. Your wife has the "practical" view. I subscribe to both, . . . depending on the circumstances. On this one, . . . Electrathon gets the nod, . . . but I have put back one that had a flaw I could not eradicate one way or another, . . . my customer was happy with his purchase, . . . I got my money back, . . . all is well. About the time I got into middle school, . . . things were being sold in the "seconds" stores that popped up like warts on a frog with poison ivy, . . . and they have been in the mainstream market all over. Leather work included as far as I am concerned. My rule is "if I can fix it, . . . I fix it", . . . but if I cannot, . . . it gets discounted and most of them went to happy customers. I still have a few. May god bless, Dwight -

Been a while since I did one of these, . . . was kind of a fun project when it was all said and done. For ammo, . . . pouch on the off side holds a speed strip. May God bless, Dwight

-

Quite honestly, . . . I did not see the error(s), . . . but then again 71 year old eyes sometimes forgive things that others don't. I am interested in the color though, . . . the upper picture looks black, . . . the bottom picture looks like a Hershey Chocolate brown on my monitor. If it is indeed the brown, . . . I'd be tempted to stamp HERSHEY on it and wear it. But then again, . . . I'm a confessed chocoholic. Don't beat yourself up on this one YinTx, . . . I like it. May God bless, Dwight

-

Mold box membrane

Dwight replied to Red Cent's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's exactly what I do Stu, . . . put it in the bag, turn on the pump, . . . pull it down, . . . do the molding with it still on, . . . works really good for me. I pulled a holster down for a 1911, . . . when it dried, . . . shoved the gun in it, . . . for a while I seriously considered cutting the gun out. Finally worked it free. I had a press, . . . it worked, . . . but with the upsurge in plastic fantastic firearms, . . . I knew it was just a matter of time until something "gave" under the pressure. That is when I went to the bag, . . . it is my "way" so to speak. May God bless, Dwight -

Let me get in here, . . . I'd like to know too............. May God bless, Dwight

-

Personally I like the two layers of 4/5 or 5/6, . . . bigger guns get heavier leather, . . . smaller guns get lighter stuff. My reasoning is simple, . . . two different thicknesses came from two different animals, . . . and will almost never dye the same. I dip dye, . . . so there is a better chance it will turn out, . . . but I just don't want to take that chance. Also, . . . earlier on I tried the "one heavy / one light" idea, . . . always seemed to be running out of one or the other. This way I don't. Just my way of doing things. May God bless, Dwight

-

Mold box membrane

Dwight replied to Red Cent's topic in Gun Holsters, Rifle Slings and Knife Sheathes

For the pump, . . . this is what I use...........http://www.harborfreight.com/25-cfm-vacuum-pump-98076.html May God bless, Dwight -

Mold box membrane

Dwight replied to Red Cent's topic in Gun Holsters, Rifle Slings and Knife Sheathes

No, . . . no vacuum box, . . . got a vacuum bag, . . . and it works wonderfully. Sometimes it works too good. I'm a "one at a time" guy, . . . prefer that to production, . . . did production in the factory for 30 years, . . . done with it. Pitch the food bagger, . . . it's made for food, . . . not for leather. See the other posts above, . . . no wrinkles, . . . no problems, . . . just a really good mold every time. Takes a bit of "thinking" sometimes to get it to come out the way you want it to, . . . but all in all I prefer it over a press, . . . actually dismantled my leather press, . . . sold some of the stuff off it, . . . never use one again. May God bless, Dwight -

Mold box membrane

Dwight replied to Red Cent's topic in Gun Holsters, Rifle Slings and Knife Sheathes

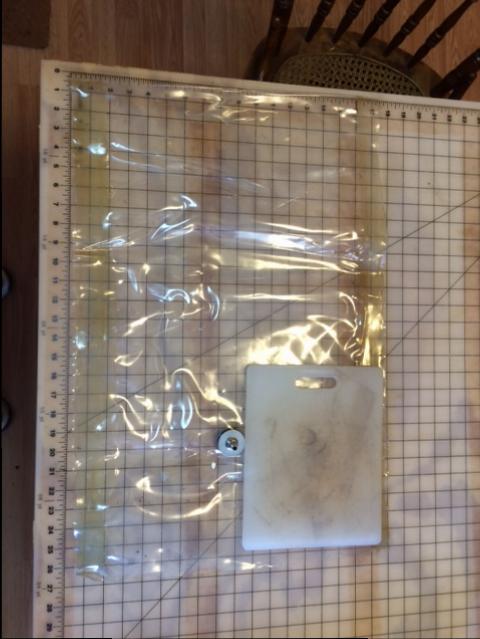

Red, . . . the material itself is .0012 thick, . . . I contact cemented a strip about 2 inches wide all the way around the 18 by 26 bag. The seal is made by two pieces of plastic pipe, . . . one has the bag wrapped around it, . . . the outside part is slotted to slide over the bag and the inside piece, . . . makes a good seal. I use the little white cutting board behind flat backed holsters, . . . keeping them from getting folded up. This has always served me well. In fact, I made a reverse fold (sewing goes down the sight track) holster for a 1911, . . . made the mistake of shoving the gun down into the holster when it dried, . . . thought for a few minutes I would cut the thing off. It was one of the first ones I did, . . . made a believer out of me. May God bless, Dwight -

Mold box membrane

Dwight replied to Red Cent's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Go to Joann Fabrics, . . . look at their clear vinyl, . . . that is what mine is made out of, . . I'll see if I can get some dimensions, . . . etc for you. But if you are doing kydex, . . . you DO NOT need a vac box, . . . just get it droopy hot, . . . lay it on the gun, . . . drop a cold wet wash cloth on the kydex, . . . it's molded. Trim and go.................. May God bless, Dwight -

Sold, pending funds, . . . Thanks to everyone for looking. May God bless, Dwight

-

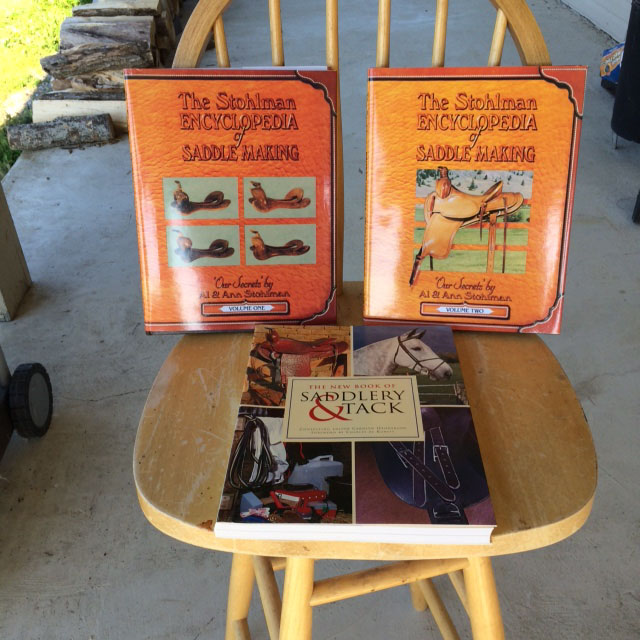

Well, . . . had this on here for 10 days, . . . nobody seems to want the books, . . . I'll drop the price to $120, . . . with free shipping, . . . If they don't sell in a few days, . . . off to Ebay they go. May God bless, Dwight

-

I once wanted to build my own saddle, as well as getting into the saddle business. Time, age, and circumstance has changed that idea. I have the Stohlman Encyclopedia of saddle making, volumes 1 and 2, as well as "The new book of Saddlery & Tack" (Carolyn Henderson, consulting editor), that I thought I would offer here before I took them to Ebay. I checked the retail price of all three books, and the retail price of all three books is in the $220.00 range. I'll take $165.00 for all three together, and that will include shipping. Just PM me if you are interested in the books. Thanks, may God bless, Dwight

-

Recreating a rare classic

Dwight replied to malabar's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Definitely a good job, . . . May God bless, Dwight -

You might want to get Katsass involved in this discussion, . . . he has used it for a BUNCH of years, . . . and if anybody on this forum could give you the skinny on MopNGlo, . . . he IS THE guy. If he doesn't see this, . . . send him a PM, . . . he's one of the good guys and if he's not out in the desert, . . . he'll answer you honestly. May God bless, Dwight

-

I get em here: http://www.letargets.com/ Put in what you want in the search window, . . . try Glock 19 or something similar. They've even drop shipped them for me, . . . cannot say enough good things about these people, . . . May God bless, Dwight

-

I bought most all of mine from Law Enforcement Targets, . . . their Glock 19 model is $39.95 as an example. They have always been a great company to deal with, . . . May God bless, Dwight

-

If you have an electric motor driven burnisher, . . . beeswax can do some super edges on holsters and belts. Now, . . . we're not talking that junk that is sold in hobby shops and is some kind of beeswax / petroleum mixture, . . . or any of that stuf. We're talking the real stuff, . . . put a bit of water on the edge of that belt, . . . hit it on the burnisher, . . . turn it light tan by pressure, . . . that warms it up a bit, . . . then rub the wax on the belt edge just so you can see littlt globules of wax here and there on the edge of the belt, . . . then go back to the burnisher. Whew, . . . should be shining like a silver dollar now. Least ways that's how I do it. May God bless, Dwight

-

Yes, Monica, I do, . . . just as electrathon said in his post above. I developed my system years ago, . . . ALL my dyes are diluted 50/50 with thinner, . . . which makes my dye ALWAYS the same. The leather may take it differently, but at least when I started out, . . . all things were equal. Most of my work is not "color critical" as I deal in a lot of dark browns, black, and an occasional saddle tan. May God bless, Dwight

- 22 replies

-

Would you seriously dip dye that big of a piece? Of course I would, . . . In order to do that piece, . . . I would find myself a cake pan that was longer than 25 inches, . . . or some similar container. Presently my widest one is only about 20 inches wide, . . . and I rarely use more than 3/4 of a quart of dye in it, . . . start one end through the dye, . . . snake it down over the edge, . . . into the dye, . . . up and out on the other side, . . . the dye is something in the neighborhood of 1/2 inch deep in the bottom of the pan. JMWendt has good results with airbrushing, . . . I prefer dip dyeing, . . . it's just the old saying "more than one way to skin a cat". The biggest piece I recollect dying for a specific job lately, . . . was a tote bag I made for a lady. The big piece was about 18 by 40, . . . dipped, laid out to dry, and cleaned up in less than 10 minutes. May God bless, Dwight

- 22 replies

-

Good job JMWendt, . . . mine is along the same lines, . . . I just made my burnisher myself, . . . mounted it to the motor, . . . turned the motor on, . . . then took various files to the piece of wood to get the grooves I wanted, . . . works like a champ. Part of the lure of leather work to me, . . . it is simply the opportunity to be creative in how one does things, . . . not like a machine shop where dedicated and precisely demanded equipment is necessary. May God bless, Dwight

- 42 replies

-

- edge paint

- polishing

-

(and 1 more)

Tagged with:

-

The reason "People always recommend dip dyeing or spraying when dying big piece" is very simple, . . . it works. If you want to spend all your waking hours trying other ways, . . . have at it, . . . but these are time tried and time proven to be totally effective. Also, . . . I would not sell a product that was not dyed through and through. I've messed around with spray dyeing and only use that for special accents on a product. The base leather is dip dyed through and through. What you save in dye over a 5 year period, . . . you will lose in customer complaints if there is any abrasion or scuffing on a dyed piece such as in the video you linked to. That leather will even lose it's dye color the first time it's owner makes the mistake of leaving it where direct sunlight can bleach it out, . . . that does not happen as readily with dip dyeing. Dip dyeing is in my opinion, . . . THE WAY to do it, . . . has never failed me. May God bless, Dwight

- 22 replies

-

Hey, Pete, . . . don't forget to post up pics of the final product, . . . let us all see your "secret tool". Seriously though, . . . this is one of my favorite forums, . . . sometimes just get on here and read, . . . kind of like the old high school cafeteria where you could just go sit down, . . . and catch snippets of a half dozen conversations all at the same time. Those were fun times many moons ago, . . . but this forum, . . . in it's own way, . . . brings that back to life again. May God bless, Dwight