-

Posts

5,257 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

You are right about the holster needing just a bit more grip, . . . I intended to do that with a bit of cant, . . . and somehow it just didn't get programmed into the product. I went all summer (after building the hot box) without using it, as I have both a door and an large window facing the South, . . . and I use them to dry most any thing I have, . . . and it is usually "overnight". I started 2 holsters Sunday late afternoon, . . . just for kicks and giggles, . . . and finished the second one this morning (putting on two snaps) before I put it in the post office to go to Arizona. Man how I wish I had done this so many years ago, . . . as I would be all cranked and ready to work, . . . but everything is drying / wet / damp / or something, . . . so I'd quit for the day. Now, . . . if I've got three projects going, . . . I can pretty well go non stop until I figure the sheets and linens are calling. I won't get a lot more done, . . . but it'll be more fun doing it. Next up: 2 cell phone cases / holster / belt / and a set of armor for a Roman Centurion. May God bless, Dwight

-

OK, . . . don't beat up too bad on me over this one, . . . it is my first "Slide Cake", . . . and was done in less than 24 hours: design / pattern / cut / sew / mold / dye / fit / buff / and final finish. What made it all work was the hot box. AND, . . . we found a name for it, . . . the slide cake, . . . because it "slides" on my belt a little bit. Now, . . . I did pull a big boo-boo, . . . locating the thumb break, . . . had to move it, . . . so three rivets fill in the otherwise blaring holes, . . . BUT, . . . I am really pleased with it, . . . far more than any pancake I ever had or made. AND, . . . it just might become a regular in my carry rotation. Anyway, . . . it's fun to have good news, . . . just wanted to share, . . . May God bless, Dwight

-

Tell me about your "Hot Box"

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well, . . . did a bunch of things down thru the summer, . . . never needed the "hot box" for what I was doing then. Got to thinking about it today, . . . no real sun for hanging in the window, . . . Made two holsters today, . . . and the concept works great, . . . and no problem with it "overheating". It dried one holster I dyed in about 2 hours, . . . dried the Resolene applications for 2 holsters in about an hour, . . . (I'm wearing one right now that I put resolene on earlier today, . . . normally would never have done this, . . . but the hot box makes it so workable). Got two cell phone cases drying in there right now, . . . did the old water forming trick, . . . waiting for them to dry. Been in there about 3 hours so far, . . . Just wanted to give everyone a heads up, . . . and the good news that the design works, . . . you want to copy, . . . jump in there, . . . but you gotta use your own wood. May God bless, Dwight -

Everyone pretty much knows what a pancake, . . . Tom 3 persons, . . . snapcake, . . . Rhodesian, . . . SOB, . . . cross breed, . . . and other holsters are called. What is the nomenclature for a pancake that does not have holes punched for the belt, . . . but instead has a short belt tunnel on each side of the gun? I have seen them in pictures, . . . never in person, . . . decided to make one, . . . have no idea what to call it. Slip cake? Slide cake? Anyway, . . . just wondered. May God bless, Dwight

-

Many of us are in the same boat: grew up in the US, . . . I can measure almost anything we commonly use or work with because I know dimensions of my fingers, . . . the span of my hand, . . . the span of my arms, . . . the length of my step, . . . etc. Off to the far East for several years in the US Navy, . . . got introduced to metric, . . . about the time I got comfortable (sort of) I'm back in the US. Later, . . . the US has an extra curricular affair with metric, . . . didn't go well, . . . but foreign cars and tools we buy are metric, . . . so like you said Pavel, . . . two rulers. In my shop I have three tool boxes for wrenches. One devoted to metric, . . . one to normal, . . . and one that houses tools that don't care. Just a fact of this "modern", . . . global economy world we live in. May God bless, Dwight

-

FWIW, . . . when I got my Boss, . . . I got several different weights of thread, . . . mostly from Springfield Leather. Bought a spool of 346 at Tandy's also. I only use one other thread, . . . 400, . . . and it is ONLY for special projects. 346 goes on all the other stuff, . . . the thread from Tandy is so easy to work with, lays down beautifully, . . . May God bless, Dwight

-

I don't recollect who it was a number of years ago, . . . said only to use beeswax and neatsfoot oil in equal WEIGHT. I make mine in a glass jar sitting in an old cheap crock pot from Salvation Army store. I don't use it on a lot of projects, . . . use a little heat from the heat gun when I do, . . . It's only for special customers. May God bless, Dwight

-

Tooling hardened leather armor

Dwight replied to TranscendentalTopiary's topic in Historical Reenactment

Personally, . . . I have never had good fortune working with leather that was previously hardened, . . . it's just not the (pardon the pun) nature of the beast. OTOH, . . . for what you want to accomplish, . . . take your leather, . . . cut it to the dimension and shape you desire, . . . stamp and tool, . . . and then dry it in a drying box that DOES NOT exceed 140 deg. F. Let it hang in there until it is completely dry. If you want to then harden it, . . . dip it in liquid beeswax, . . . you can then attach this to your armor with contact cement and stitching, . . . it WILL NOT COME OFF, . . . and if properly done, will not degrade the strength of the armor. I've done this with some small pieces for special circumstances, . . . and that piece of leather is super hard, . . . maintains definition, etc. May God bless, Dwight -

I would probably also prefer as LumpenDoodle2 said, . . . to use the M&M system, . . . But if you had been here in the US when it was attempted a couple decades back, . . . y'all would understand our reluctance. I don't recollect which way it was, . . . but the Japanese version of metric was one size and the German version was either a tad smaller or a tad bigger. You had to have three sets of wrenches to work on cars, . . . or at least two. Same went for screws, . . . the phillips head on a Japanese screw did not mesh with a German screwdriver, . . . and it was so disconcerting, . . . a lot of us just balked and said forget it. Even now, . . . mechanics still have to have two sets of wrenches, . . . But at least in leatherwork, . . . a knife cut is a knife cut, . . . no M&M or Inch, . . . just cut. May God bless, Dwight

-

I think you will find that the majority of us on here are into inches, feet, yards, etc. FYI, leather is typically measured in ounces, . . . and usually addressed in the format x/y ounces: for example 4/5 means at least 4 ounces in thickness, . . . but not over 5 ounces. Ounces are each 1/64 of an inch. Therefore, . . . a piece of leather that is exactly 8 ounces in thickness would be 8/64" or 1/8 of an inch. A few from Au, . . . UK, . . . Sweden, . . . etc. seem to be entombed in the mack-rack or M&M ideology. Can't be too hard on em though, . . . that is what they learned growing up, . . . and sometimes it is hard to change. Fortunately, . . . I can relate most of their posts to 7.62 mm or 5.56 mm as I just happen to be well versed in those two measurements. If I were not, . . . I'd have to google their mm measurements every time. May God bless, Dwight

-

It works out a lot better to burnish the edges before you put on anything like edge kote or Resolene. The beeswax will hold the fibers down and give a nice smooth finish, . . . but it is better if you only use the beeswax and water. The other concoctions have oil and other additives that can dilute and/or attack your finish, . . . The "finish", . . . should be exactly what that name implies, . . . "finished". Doing anything after Resolene is hard at best, . . . and many times is a waste of effort. May God bless, Dwight

-

Thanks, Chief,...... Have to give them a call come Monday. May God bless, Dwight

-

Hey, Folks, . . . looking for somewhere that I can buy a 24 inch by 24 inch piece of "nice" veggie tan leather. Cannot have any scars, holes, etc, . . . but does not have to be Queen Elizabeth perfect either. Must be at least 12 oz, . . . and I really have no need for any more than just that one piece. Ideas anyone??? May God bless, Dwight

-

Can't tell about the walleye, . . . if I need a few, . . . Kroger is still in business. Crappies and catfish are the local favorites. I haven't been fishing in years, . . . probably won't be for a while either. May God bless, Dwight

-

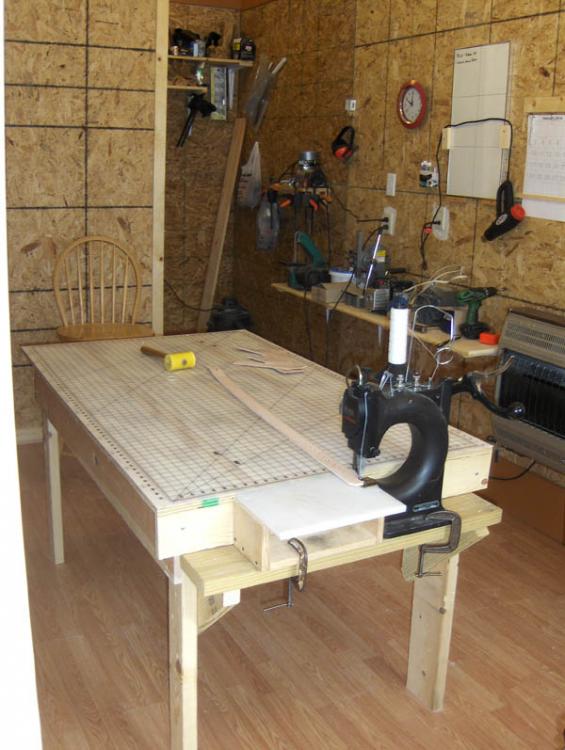

The mat on my table is available at Joann's Fabric, . . . get the coupon from their website, . . . can get up to half off, . . . I love mine. May God bless, Dwight

-

I'm sure if you shopped around enough, . . . somebody makes leather scented candles, . . . you could just light one every other day or so, . . . kind of make ya feel at home. Plus instead of hand sewing a holster, . . . you could take up fly tying, . . . ya gotta catch bait fish anyway if ya want them biggie muskies, . . . Seriously, . . . have fun, . . . my wife and I discussed selling out and moving, . . . decided to stay put, . . . we'll just hope and pray for the best for you and yours. May God bless, Dwight

-

I've made a somewhat of a copy cat version of the carjacker, . . . My version is it is a simple holster, . . . sewn at the bottom (along the trigger guard edge) and a flap that is attached to the sewn edge with Chicago screws. That flap just simply starts at the bottom and goes up and over, . . . till it snaps. It really is not complicated, . . . just 4 total pieces of leather, . . . little sewing, . . . one snap, . . . 2 Chicago screws. The key is to get it at the angle you want it on the belt, . . . and you sew a couple pieces of leather to the inside so when it is cinched down on the snap, the pieces of leather lay one above your belt and one below. They are 3/8 of an inch wide, . . . about 3 inches long, . . . and cut from 9/10 leather or slightly thicker. They sew to the flap. I don't have one now, . . . but I've had one, . . . and for certain applications, . . . it is sooooooooooooooo nice. And for clarification, this is not a picture of mine. Mine actually was much more crude than this one. This is an image of the actual "Carjacker" holster, . . . which I just happen to think is a masterful invention. May God bless, Dwight

-

Ruger Super Blackhawk Cowboy Holster

Dwight replied to SLP's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Edges look real good, . . . stitches too. Overall design is excellent, . . . as well as the staining, . . . and the edge treatment of darker color and the tooling really adds to the overall effort. One "criticism" so to speak: put your female screw parts between the two layers of leather. The way you have them now, . . . they will rub the garment the wearer has and will in time harm the trousers. John Bianchi was very adamant in his teachings to hide the screws and rivets as much as possible, . . . and it is especially easy in a two layer rig, . . . makes it overall a tad cleaner looking, . . . and does not subject the owner to metal rubbing on the accompanying clothing. This is especially important to those who go cheap and use plated steel rivets / chicago screws. Two, three, or four good sweat soakings and the plating can peel, . . . rust follows, . . . and it can be real ugly. The only other critical thought may not be applicable, . . . but it looked as though the holes for the hammer thong were a bit large, . . . making the thong dependent on length. I like to make mine so the friction in the holes is the "holding factor" and can be adjusted for length if another weapon is inserted. BUT, . . . again, . . . let me emphasize that the overall holster is excellent. May God bless, Dwight -

Thank you, . . . I navigate through the Caledonia area from time to time, my son lives up near New Winchester, . . . off 294. Again, . . . toying with the idea of making one for the leather shop, . . . it would showcase some of my work, . . . whereas my old Jumbo is just a fixture in there. Thanks again for the info, . . . gonna have to mull this for a while. I especially like your design as it is very near the Jumbo in design, . . . and IT IS a comfortable saddle. May God bless, Dwight

-

Obviously, . . . we must be doing something different. First, . . . I only use Feibings black oil dye, . . . I gave up on the USMC black several years ago for the reason you mentioned, . . . the rub off. Secondly, . . . I always thin the black down, . . . 50/50 dye and thinner. Third, . . . I dip dye, . . . a quick dunk, . . . no more than a couple of seconds in the liquid. Fourth, . . . I .....LET IT DRY, . . . DRY, . . . DRY. Black sometimes takes longer, . . . so I give it the time to dry really good and dry. Fifth, . . . I buff it hard, . . . using a terry cloth wash cloth (salvaged from my wife's rag bin), . . . and I buff it like I'm trying to rub the black color off the leather, . . . hard, . . . using some real force. Sixth, . . . a 50/50 single coating of Resolene, . . . brushed on with a bristle hair brush. Let it dry, . . . lightly buff, . . . and I have zero, rub off using that formula. May God bless, Dwight

-

I bought some thread here, . . . some there, . . . some other places. Results also were "here and there". The thread I buy from Tandy, . . . have never had any problems with it at all. Thus, . . . my thread comes from Tandy. All my sewing is either my Tippmann or hand sewing, . . . and I use the same thread for both. May God bless, Dwight

-

Right now I live in Marion County, . . . our mail box is in Delaware County, . . . across the street. Another "curious" question, . . . if you had to put a number on the hours you spent on that particular saddle, . . . got any idea how many would be there? I'm toying with the idea of making a new one for my shop. I'll use it in a parade or two, . . . but it'll be more of a shop decoration than anything else if I make it. May God bless, Dwight

-

Thanks, cowboycolonel, . . . that is one pretty saddle you have there. The old cowboy that had mine used a bunch of little stamps on it, . . . trying to dress it up some I guess, . . . but it never was as good lookin as yours. I also really like the back of the seat, . . . sitting straight up, . . . my kind of saddle. Nosey question: where did you get the tree? May God bless, Dwight