beltbuckles

Members-

Posts

111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by beltbuckles

-

Glue alternative to lining wet formed items with suede

beltbuckles replied to BDAZ's topic in How Do I Do That?

so, im struggling to picture how this all works out, but this could help me.. is there a video or demonstration of how this process works... is this still what you are currently using? -

Rivets - rapid vs. tubular vs. double cap

beltbuckles replied to epiphanist1248's topic in Hardware and Accessories

i use double cap, they are decent but you have to get the correct lenght.. some people hate jiffy caps but... to each his own.. ive heard the copper rivets are the best you could use chicago screws and glue them- 8 replies

-

- rivets

- rapid rivets

-

(and 2 more)

Tagged with:

-

soaking veg tan leather ( grey lines appear)

beltbuckles replied to beltbuckles's topic in How Do I Do That?

it looks like the color is coming from within..... looks like newpaper was rubbed on it... but when it dries i think it goes away a bit... odd -

so i noticed that when i have a clean looking piece of veg tanned leather.. i put some water on it and i get these odd grey lines and grey areas... like i rubbed it on newspaper or something.. i though i was maybe rubbing on something on accident or something like that... NOPE, i tested it and got a clean piece and added some water and right away the grey marks and lines appear.. is this normal?> (ps, i noticed it on thin 2-3 ounce, not so much the 5-6 ounce)

-

sounds about right,, i posted on the "how to do that" with a how to sew corners ... basically asking about methods.. i do feel that the one you describe is a solid way to do it.. i tried gluing it with weldwood then sewing it but it didn't go well... soaking the leather then sewing it came out better... but if i could get a really good mold then glue it.. that could be the best. (thankyou by the way) what about a consew 227 any stainles stuff on that ? oh and the tension.. i find that the top tension is really light usually when i sew stuff... (veg tanned) -thankyou by the way

-

i was never good at edgepainting (hopefully this will change really soon) but i have heard that you need to use edge paint and do many many layers for it to come out decent.. its a process... unless you use an expensive machine to do it Insert other media

-

the problem is that i need the leather wet to be able to bend it while im sewing.... the problem is that i need the leather wet to be able to bend it while im sewing....

-

so when i sew vegg tanned leather and i have it wet to be able to mold it and sew it well.. is that bad for the machine?? do i just dry it by dabbing it with a towel or paper towel after?

-

i read a thread on this forum about it and i did some searching already... so here is the situation i am doing a veg tanned bag. sewing the seems on the outside.. please see pic. i will be using a cylinder arm sewing machine i am using 2-3 oz on the sides with about 4-6 oz on the front part i tried gluing it with weldwood, didn't work that great i tried getting the sides wet, but it stretch on one side, and i had to cut it even.... is that normal? what is the best way.... i have a little wooden piece with a half circle bend in it to try to mold it around... how do you guys do it ??? -thanks

-

getting the 2 different veg tanned color pieces to match

beltbuckles replied to beltbuckles's topic in How Do I Do That?

i may have to try leaving it in the sun i see your point.. how hard is it to dye something? how much time does it take? -

so i have a few different pieces of veg tanned leather. they are different ounces in thickness for different parts of the bag that i am making.. however, the color is different.. different shades of the pale (undyed) color. so how could i get them to match if i don't want to dye the bag a color, just keep it the pale (undyed) color... i heard leave it in the sun ( some parts that need to be darker) also conditioning,, but i don't want to condition one part and not the other.. any advice?

-

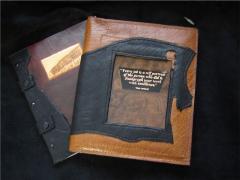

SketchbookCoverAndAlbum.jpg

beltbuckles commented on ColoradoGirl's gallery image in Our Leatherwork Galleries

-

yup, i removed the plated first before drilling.... so i started playing with the tension and making it loose and tight.... making it loose helped but the sticking was very poor. anyway i got the tension back to normal and the problem is still there.. i started sewing really slowly and i kinda hear it get caught on something... not sure what..?? i think it may be the tread spool,, i set it up so it would flow better, ill tried just having extra thread loosely sitting there and it sewed okay...

-

BEAUTIFUL!!!!!!!!!!!!!!!

-

i tried different needles... same thing... i looked at my throat plate.. it does have a little spike coming out of it.. ill try to grind or smooth it out tonight.. see if that helps i actually tried to run the machine without the throat place just to see if it cuts the thread... .bad idea i need strong thread for the stuff i make.. (handbags) would polycore be any good, or should i just stick to nylon

-

okay, thank.... very nice, once again!

-

so you just taped it off then dyed it?

-

very nice job!! so you edge paint the handles? and burnish.. ? .

-

i am using a juki 5550 for on synthetic suede.. thick but not to thick.. definately sewable.. anyway, my top thread keeps shredding.. hmmmm.. i changed the way the thread is fed to the machine.. it doesn't have a spool holder so i kinda made one.... i am using a size 18 db x1 (110) needle. thread size is about 69, maybe a little bit bigger... so i played with the tension, (the bigger knob, not the top little one).. and that i continue to have problems.. i am using 2 types of thread.. one good quality, the other one is some upholstry from walmart.. i have more problems from the walmart one, but i don't think its the tread... i did start using the size 18 needle, not sure what the size was in it before it.. maybe i need to adjust the tining?? it sews fine with really small thread.... maybe a bigger needle? ?

-

juki 5550 sewing thick material (foot height)

beltbuckles replied to beltbuckles's topic in Leather Sewing Machines

ahhh, thankyou very much... yeah im missing some parts to say the least... i lifted the machine up and pushed it with my thumb... so it does work, i just need that umbrella piece and a few others... thanks again -

juki 5550 sewing thick material (foot height)

beltbuckles replied to beltbuckles's topic in Leather Sewing Machines

i think the cp-130automatic is has seen better days (maybe not fully working), but it can sew okay.. anyway, the oil tank has a knee lift .. where do i hook it up to? my other machine consew227 is simple, it has the chain and stuff in the back.. anyway,.. if i can't hook it up.. is there a way to manually lift it (other than pulling the foot up by hand).. is there a lever (other than the hand lift one that doest go up high_)?? -

juki 5550 sewing thick material (foot height)

beltbuckles replied to beltbuckles's topic in Leather Sewing Machines

my machine has this juki cp-130 nonsense on it.. some weird automatic junk.... (is it possible that is it not set up for a foot or knee lift? -

so i was trying to sew some synthetic suede on a juki 5550.. i was trying to do about 5 layers and i had a hard time getting it physically under the pressure foot.. it really wasn't thick at all, but the foot only lifts up a little bit.. is there a way (or lever or button) that makes it go up higher.. ( my walking foot goes way higher..)