-

Posts

56 -

Joined

-

Last visited

About KittenThrasher

- Birthday 03/15/1958

Profile Information

-

Gender

Male

-

Location

UK Peak District

-

Interests

Leatherworking, computers, archery and the great outdoors,

LW Info

-

Leatherwork Specialty

Making something I haven't made before.

-

Interested in learning about

My new laser cutter/engraver and Singer Patcher 29K15

-

How did you find leatherworker.net?

Can't remember, been spying on you for years.

Recent Profile Visitors

3,120 profile views

KittenThrasher's Achievements

Member (2/4)

-

Which leather burnishing machine to buy?

KittenThrasher replied to rivetandchain's topic in Leather Tools

I've played with Tandy's burnisher and in my opinion it was massively underpowered and overpriced. you can do a lot better from Justwood.com for less money. (ps I don't work for them or have any relationship with them.)- 30 replies

-

- burnish

- burnihsing

-

(and 2 more)

Tagged with:

-

Beautiful Sheath Ruined Furniture

KittenThrasher replied to zoomer56's topic in Leatherwork Conversation

Looking at the stain on the furniture it looks to me as if the stain is also present under the handle of the knife which is not leather. Makes me wonder if the problem is actually the sheath or something which has caused a 'shadow' under the whole thing which is not caused by your (rather excellent) work.? I'm not sure if I'm seeing the stain very well on my laptop though. Just a thought. -

My experience is similar to this, I got a 30W laser a few weeks ago and am still learning (quickly) the most recent thing I've corrected is the focus point, with this now correct the charring is a lot less bad. It's still easier to use the machine for marking out though. At the moment while I'm still getting a grip on it I'm using it to cut out patterns in 3mm acrylic (from DIY store for glazing shed windows etc, works great for this purpose. ) I'm looking forward to using it for a lot more over time.

-

all of the above plus speed clamps with rubber and leather bits glued on to stop damage to my rulers, quilters thingy's, and other bits..

- 14 replies

-

- rulers

- grid rulers

-

(and 1 more)

Tagged with:

-

Turn the Awl handle in the normal way - probs in a collet chuck, then put a fine drill bit in through the tailstock end get it well into the handle end, as deep as you want the blade to go. then pare off the handle. the traditional way to set the awl pointy bit is to hold it in a vice between two softer bits of metal, (I used to use penny coins until they started making them out of Friggin iron!) then tap the handle on forcing the awl into the 'slightly too small' hole that you drilled on the lathe. the size of the hole will depend on the awl, the wood and whatever drill bits you have lying around at the time. 'Hope that's pretty clear,

-

Which leather burnishing machine to buy?

KittenThrasher replied to rivetandchain's topic in Leather Tools

It's not hard to take off the grinding wheels, normally just a 19mm 3/4 spanner. one end is likely to be a reverse threaded nut though, so just look for that. The only difficulty I found was that the spindle needs to be a very good fit in the burnisher drum and/ or sander. otherwise it won't run true. I had to do a little bit of sanding to get the spindle to a perfect fit. There are also a few different size spindles on bench grinders, I have one with a 16mm spindle, one with a 14mm spindle and one with a 12 (which is a bit smaller than 1/2 inch) so check first. My motor is 200 watts running at 2800 rpm which is more than enough for my needs which aren't very demanding. I was also interested in Bikermutt's comment above that 3450 rpm is too fast, my machine runs at 2800 rpm and seems pretty ok, maybe it depends on what you doing with it or just the way you use it, I'm going to try a slower speed out of curiosity though. been playing with a 150 watt speed controlled motor this morning and the main thing I found was that it is massively short of torque at high speed settings, putting a 4mm piece of VT on it with moderate pressure just stopped it dead! not much use really. good luck. :-)- 30 replies

-

- burnish

- burnihsing

-

(and 2 more)

Tagged with:

-

Which leather burnishing machine to buy?

KittenThrasher replied to rivetandchain's topic in Leather Tools

PS The drum sander quickly turned out to be great for thinning down the end of straps instead of getting the skiving knife out.- 30 replies

-

- burnish

- burnihsing

-

(and 2 more)

Tagged with:

-

Which leather burnishing machine to buy?

KittenThrasher replied to rivetandchain's topic in Leather Tools

I just bought one of Nigel Armitage's burnishers from justwood.com, it's a good quality burnishing drum made of Ash with a sanding drum on the other end like the Tandy one, however this one is a LOT cheaper and rather better quality. Your can also buy the burnisher and/or the sanding drum separately if you have an old bench grinder laying around (which is what I did) that way I got a really nice burnisher for about £100 I visited the people at Just Wood and they were great, very helpful and friendly. A basic 150W cheap bench grinder set up with the burnishing drum is plenty powerful enough for most uses. Mine started to get a bit warm after an hour or so but wasn't that bad. I've seen one of the Tandy ones and TBH it really isn't as good. even with variable speed.- 30 replies

-

- burnish

- burnihsing

-

(and 2 more)

Tagged with:

-

Rotary cutter blades are expensive, (decent ones at any rate,) I made a simple jig to mount them on a dremel where a quick 'touch up' with a fine diamond stone or even fine wet-n-dry puts a good edge back on it. Make sure they're fixed on your dremel properly though as my first experience of this resulted in a rotary blade whizzing around the kitchen at very high speed. ooops.

-

Identity Leathercraft in the Uk have an excellent method for printing on leather, good quality results from your images or design. Might be worth talking to them. Their method would be great for pet collars etc. I know they do international shipping. (I used to be associated with them but I'm not anymore.)

-

A big fat steel rule and a rotary cutter will help a lot, the fat steel rule will stop the leather moving at all (I even clamp the ruler down sometimes) and a rotary cutter (as used by dressmakers etc.) goes through thin leather without 'pulling' it at all. Acrylic templates are excellent if you can find someone with a laser to cut them for you. I used to hand cut my own 3mm acrylic templates, it's tedious but quite do-able.

-

New Knife Sheath

KittenThrasher replied to Gus90's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks like he'll be needing a new knife to go with the nice new sheath. -

Don't know anything about Bontex or webbing but that is nice work.

-

Hammer, Maul, Rock? What do you use and how heavy?

KittenThrasher replied to Killerwork's topic in Leatherwork Conversation

I used a small woodworkers mallet for years til someone told me it was 'wrong' some years later I've gone back to it. it's perfect for me. I also use a very cheap plastic headed thing on a dowel handle - that's great as well. I love spending money on tools, but it usually goes on things with a sharp edge or motors, just bought a Singer Patcher 29K in lovely condition which is fantastic to use. If it works for you, it don't matter what it is. -

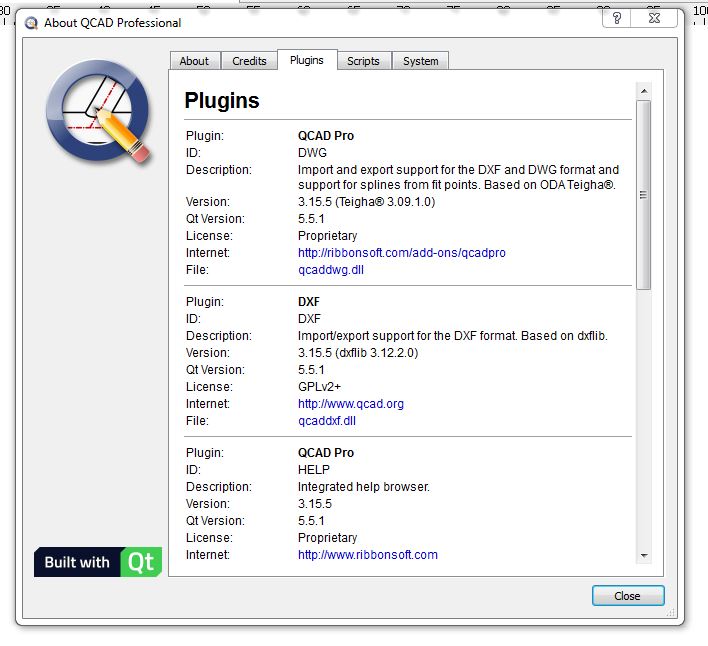

Useful, easy to use design software - and it's free.

KittenThrasher replied to KittenThrasher's topic in Computer Help

Hi Jeff, I'm thinking they've changed it a bit since I had the trial, I think mine went for an hour before I had to restart. if you scroll right to the very bottom of the download page it shows this: QCAD Community Edition If you are looking for the free open source QCAD Community Edition, you can download the trial version for your platform (see above) and then remove the QCAD Professional add-on running in trial mode. Alternatively, you may compile your own package from sources below. I'd never seen it before either, 'might be useful for a few people here. the plugins control panel thingy is in the 'Help' > 'about' tab, Good luck,