-

Posts

1,431 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Stetson912

-

Latest holster for a cop friend

Stetson912 replied to Quillleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It is a spartan helm. I believe it's A symbol of protection and fighting the good fight against a larger opponent but staying dedicated to the cause. Much like the spartan battle of Thermopylae.- 2 replies

-

- spartan

- thin blue line

-

(and 8 more)

Tagged with:

-

Thanks for the update @CaptQuirk. I have to add that I have no issues with Rogers leather and the backside is just fine. I wouldn't "finish" it because it doesn't need it. I'm sure the same goes for WC and HO leathers, b grade included. I have seen Tandy items that definitely needed it but that was before I knew better. I seldom use tan Cote for that purpose anymore. If you do for some reason need it perfectly smooth, you should consider lining it with thin leather like goat or calf. Just a thought

-

I tried responding earlier so I hope it doesn't double up. You can order direct from wickett and Craig or Hermann oak. That would be best for the best leather you can get. I know Hermann oak sends the best when you order direct but they have a minimum purchase amount of 10 hides I believe whereas WC will let you buy just one hide or maybe even a piece of one. But if you and or maybe some friends can swing it it is ultimately cheaper and better quality A grade leather. I recently got some veg tan from Roger at RJF leather co. I was pleased with it. It came split so the flesh side was not at all fuzzy. I believe he also offers a finished pasted and slicked back if you want to spend a little extra. For some reason his site isn't working for me right now so I can't actually confirm the pasted finish. He has a banner ad on this forum as well. He also offers drum dyed backs and English and European bridle leathers. It seems to tool nicely and is easy to work in my opinion. I believe he gets it from thoroughbred leather tannery. Maverick leather co offers both HO and WC leathers but are most likely b grades which can still be very nice. They offer a bunch of other cool stuff as well. As for finishing the flesh side of leather, I use feibings tan kote. Just put it on a cloth and rub it into the flesh side and go over it with a slicker, works great but takes a little effort. You may want to try on a bit of scrap first. It also adds a bit of water resistance as it kind of seals the leather. I hope this helps you out.

-

Good to know thanks.

-

Ah ok, would a space saver type bag work the same as your getup? I just remembered they have the attachment to suck the air out so, may be worth a go. Kinda a poor man's vacuum mould haha

-

Awesome! How do you vacuum mold it? Like a zip lock and such the air out? Or are there special bags you buy? And how do you find the lines to bone in? Not the main lines but the smaller more decorative ones? In this case the thinner lines that run along the bottom of the slide?

-

iPad Pro sleeve

Stetson912 replied to Shed's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Indeed, I used Angelus Jade last time I had a problem. But I was using a dauber so, should be expected to some degree. I haven't used many colors from feibings. I usually stick to the browns and tans n such -

iPad Pro sleeve

Stetson912 replied to Shed's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice! I have the same problem with dye sometimes. What kind did you use? I haven't tried dip dying yet though. Suppose I should haha. -

@AdamGadut is the idea to neutralize any remaining acetic acid/vinegar? And how do you keep them from mixing? Just a larger container with the open jar of vinegroon and a pile of soda?

- 11 replies

-

- vinegroom

- leather dye

-

(and 1 more)

Tagged with:

-

Makes sense, I've read that you shouldn't really wear your boots/shoes more than a day at a time and keep trees in em to keep them from changing too much. I was just curious what you found in your studies haha

- 32 replies

-

- shoes

- italian leather

-

(and 1 more)

Tagged with:

-

I haven't made it myself...Does it smell of vinegar? This site has some suggestions. It says to add iron if yours is dissolved and still smells strongly of vinegar or heat it up a little if it smells and you still have iron. It mentions the smell should go away (relatively) when it's balanced right(vinegar to iron) I hope it helps you out. There's also some interesting tips on using it as well. https://www.adamsleatherworks.com/vinegaroon-a-k-a-vinegar-black/

- 11 replies

-

- vinegroom

- leather dye

-

(and 1 more)

Tagged with:

-

So they really are "built to last" hehe How long will a pair of shoes be comfortable if maintained correctly?

- 32 replies

-

- shoes

- italian leather

-

(and 1 more)

Tagged with:

-

By the title I was expecting to see some colossal walnuts on your feet, but this is better hehe.. In all seriousness, they look great. I always found shoemaking interesting, I just don't seem to have the time or money to learn how to do it at the moment. Great work.

- 32 replies

-

- shoes

- italian leather

-

(and 1 more)

Tagged with:

-

Awesome. Thanks. How do you heat set it? I tried before with a low oven but it didn't work too well.

-

Looks great. I love seeing your holsters. I have to make one sometime haha. I do like that iwb design, is the opening stiff enough not to collapse?

-

Impressions on Buffalo Leather

Stetson912 replied to bristolbrandedleatherco's topic in How Do I Do That?

How is it tanned? You can't tool leather that isn't veg tanned, it won't hold the impressions. You can try heat embossing it. You need a way to heat your stamp up and some sort of press to press it into the leather, an arbor press and heat gun would work probably. You'll have to leave the stamp in the press for a few seconds for the impression to take. -

How much would you sell this belt for?

Stetson912 replied to RSmithLeather's topic in Leatherwork Conversation

Yup all good points, I'm about Midway between Tucson and Phoenix in casa grande AZ. And while I don't see many hand made leather goods or leather workers I know they are out there. There are a few on this forum. And not to mention Bob Park happens to be in Phoenix. So, my goods may not be priced as high because of the demographic and culture (rodeo and ranching and what have ya) that's around here. Not to mention the fact that...I'm NOT Bob Park's haha! Whereas you could sell yours for more because you happen to be one of the few doing it in that area. But, none of it means beans if no one wants it haha! But u ain't gotta worry about that do ya! There's a lot that goes into pricing but like old n slow said don't give it away, it took you time and money to make. As a hobbyist I say cover expenses and add a little extra but stay in the fair range 60-70 bucks, but if you're trying to expand add 100-120, you could probably get more. It looks like a good product. -

How much would you sell this belt for?

Stetson912 replied to RSmithLeather's topic in Leatherwork Conversation

I'd listen to NV, that's right in the ball park of what I'd recommend myself. -

I second that bodean, I ordered from them and had it in 2nd days

-

I bet you're a real... Ahem... Fungi... To be around

-

new wallet back stamp

Stetson912 replied to Studio-N's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That should be the new smiley for Walmart... As an employee, I can say two face is fitting. Haha -

Yup the white lightning one. I did notice the pebble grounder in the other piece too but it's more spread out and not repetitive like the white lightning one. But that's what scraps is fer. Haha. I still love your work and still am jealous. Haha.

-

measuring belts for western/plate style buckles

Stetson912 replied to jasonmccluer's topic in How Do I Do That?

I'm making one myself. The buckle should be here today. Just have some letters to tool and we will see how it looks. I'm using a double shoulder I got from Roger at rjf. Seems nice so far. Look forward to seeing what ya make -

measuring belts for western/plate style buckles

Stetson912 replied to jasonmccluer's topic in How Do I Do That?

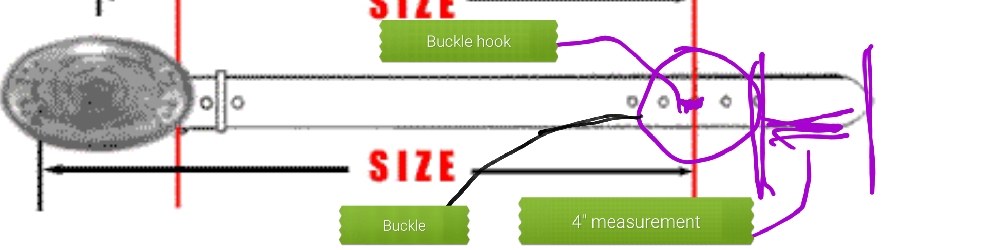

Yup, that's exactly how to do it haha. I've seen also to put the hook end of the buckle where the center hole will be and measure 4 inches from the end of the buckle and add that to the billet end just to be sure you have enough length to get through the buckle. (Using the image jls provided above, you measure to the right 4inches) hope it helps. It good to make sure there's enough billet, it's a lot easier to cut off some leather than add more hehe