MarkCdub

Members-

Posts

115 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MarkCdub

-

The little skiving I have done has been with the tandy skiver with replaceable blades. I had a hell of a time until I implemented lightly casing the leather before skiving. It really allows the blade to do its job with less friction and gives you more control. Just don't get it to wet or you open up a whole different set of problems. Grab some scraps and give it a shot. Also as others have said, stropping your bladed, even new ones makes a world of difference. Good luck!

-

Ok, so this picture is not my work. Sorry for the confusion. I will be making 4 similar to this design since that is what the customer asked for. I have not made this yet and that is the reason for my questions. My current stitching set up is 5 mm chisel, .8 mm ritza tiger thread (I thought it was 1.0 but I was wrong), and 002 john james needles. In my projects I have wondered if my thread was to thin for the chisel size. I know I just need to buy a couple different size chisels and threads and just try them out but I am on a tight budget, atleast until I get these holsters complete lol. I want the stitching holes to be smaller, I'm pretty sure the 002 J.J. needles will be too big for for the 4 mm chisel holes. What would be the proper size J.J. needles for 4 mm chisels? The depth and the friction from the suede side of the leather and it being molded to the knife plus the tension from the belt passing through the loops should keep the knife secure.

-

I am going to be making 4 belt sheaths like this. My current stitching chisel is 5 mm per stitch but I feel like the stitches will be to large for such a small item. I'm thinking about buying a 4 mm per stitch set of chisels and I'm wondering if .8 or .6 tiger thread would be best for the 4 mm stitch? Second question is about antiquing. How does antiquing look on un-dyed veg tanned leather with a mink oil and top coat treatment? Thanks in advance, these will be for my aunt for Christmas gifts.

-

I agree with the north/south stitching. I could not figure out how to keep in sturdy enough in the pony while stitching. Also because I used a stitching chisel, my stitches flattened out. I'm not thrilled with the way my stitches looked after I hammered them flat. I think next time I will try to put a groove so the stitches will sit flush with the leather or maybe not flatten them out. I will be ordering another set of stitching chisels at 4 spi, I believe these are 5 spi so it will give ke another chance to improve.

-

Hunting Ammo belt case

MarkCdub replied to DuqQuaid's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the shout out. I never thought to make an ammo pouch in that manner lol. I've never had anything that I made inspire someone to create something. I will be making some ammo pouches for friends/family now. I love the ruggedness of it. The only concern I have is with the minimal stitching on the belt loops. I feel like the first time you squat down or it grabs ahold of something those stitches will fail. I would also make the loops wider to allow for more stitches. -

The answer to your riddle. Consumerism and competition. There is alot of competition for our money in the US, most people don't know or care about the difference in quality between your piece of art and a collar made by a machine or low skilled worker in China. They only see the price of your collar and the price of that Chinese collar, and I can imagine your collar is atleat 5 times more than that cheap Chinese collar, and those customers won't pay for your collar because they don't see the value. It is a problem with all craftspersons in the US too, people dont appreciate the quality difference and most don't see the value when they can buy the cheap one and "it does the same thing". Don't take it personal, those collars are awesome.

-

Need to identify saddle scabbard tooling & history

MarkCdub replied to butchlambert's topic in Leather History

I just hope everyone realizes those symbols are Native American symbols and NOT swastikas. Apparently the nazi symbol faces the other direction. Good luck finding out about it though. -

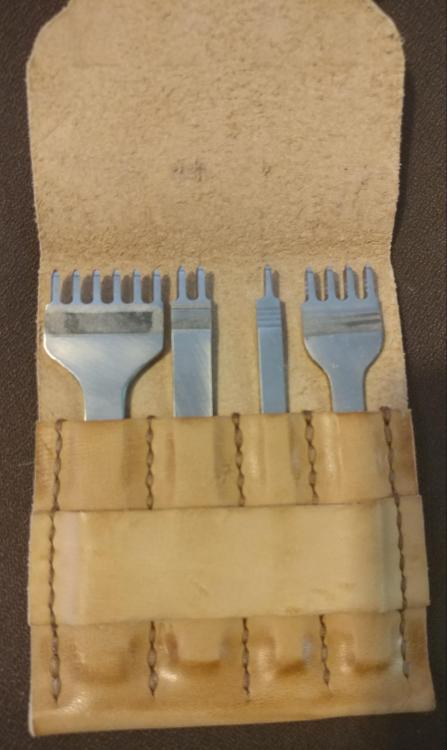

Thanks, lets just say it was pretty hairy getting the chisels in the case. I have some battle scars and the chisels drew first blood lol. Once I got the chisles in the case, I dunked the whole thing in water for a second or 2 so I could make the cover fold, and burnish around the chisel handles to loosen up the slots. Works good and they slide in and out with just enough friction so they dont slide out accidentally. Ive got the pattern making and sewing down well enough, now I just need to figure out how to cut the leather easier...

-

Paddy Rock Trucker

MarkCdub replied to AndyL1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I like it alot. I'm working on a simple bifold minimalist wallet and I am having a really hard time cutting out my pattern. I think i need to transfer my pattern to some thicker card stock because nothing lines up right and probably need some sharper blades. Anyway, sorry to hijack your post but I would love some pointers if you have some, T-pockets are my nemesis.- 10 replies

-

- wallet

- long wallet

-

(and 2 more)

Tagged with:

-

My First Post!

MarkCdub replied to SkinBender's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Really glad to have you here. Im fledgling at best, you obviously have skills and your knowledge is welcome here. The sheaths are awesome and the knives are really nice (I like the first knife with green handle!!!). Welcome and don't be surprised if you do more teaching than learning because your skills are far superior to mine. -

Waist bag

MarkCdub replied to csoty's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice! -

Recent Projects

MarkCdub replied to stormcrow's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Do you hand cut your leather or use a press and dies? -

Wild deerskin passport wallet

MarkCdub replied to stormcrow's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I love it! The stitching as perfect. What spi and size thread did you use? -

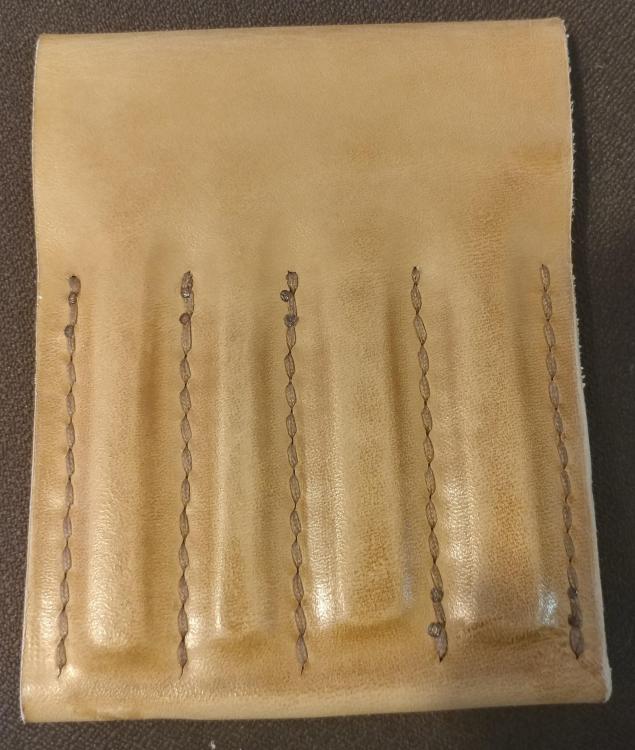

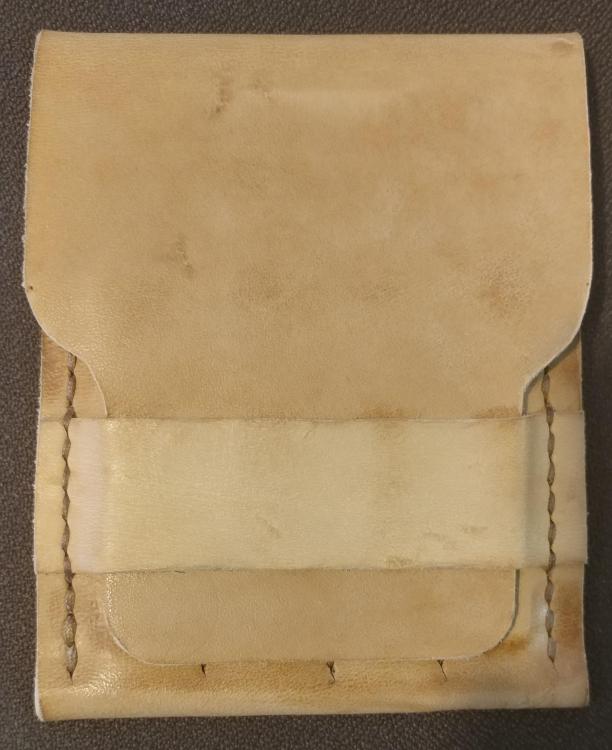

I wanted a relatively quick and easy project. I'm trying to get back into it and I wanted a "win" to get me going. I made this case for my stitching chisels. Not great, but I like it and its functional. Plus it was good practice for stitching and cutting.

-

Yeah, this where I'm at right now. I am letting the fold dry, I wet it so it would fold and hold its shape. Once its dry, Ill glue the edges, punch and stitch the pockets, then glue the closure strap, punch and stitch the edges and done.

-

So I rearanged the spaces so the 6 and 4 had less room between the stitches and rather than stitching 3 sides to create the pouch I decided to fold the bottom over and stitch up each side. I also pulled a scrap piece of 5 oz and it is more supple than I thought it was (last time I picked it up by the hanger area). Im using 5 oz, gonna give it a go since I don't use that hide for much right now. The lighter leather I'm working on some wallets.

-

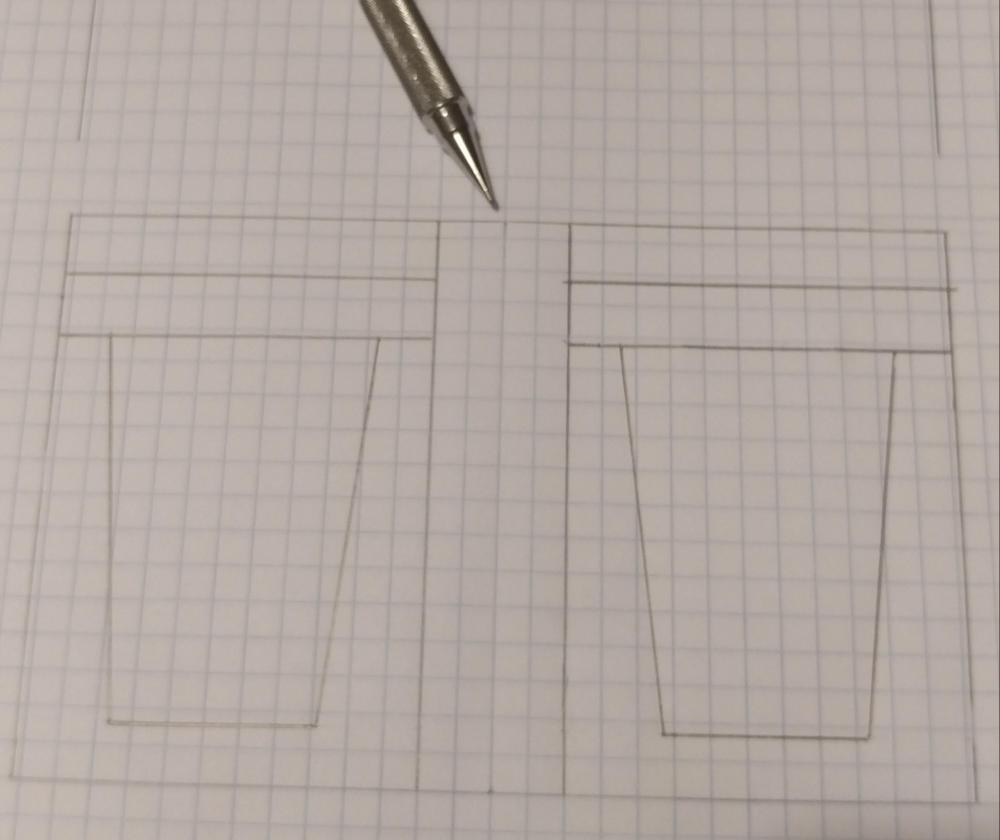

I drew out this pattern for a stitching chisel case. I have some 1-2 oz and 5 oz leather that I'm probably going to use to make the case. The 1-2 oz seems too thin/flimsy and the 5 oz is really stiff. Any ideas? Am I just SOL with the current weights I have? Also, do you think my stitching lines will give me enough room for the chisels?

-

In the drawing its 1". I took my front pocket card holder (same thickness as bifold will be) and wrapped a strip of the leather around to get an idea of how thick it needs to be and it looks like 3/4-1" is about right. I'm gonna leave it at 1" and see how it turns out. Thanks RockyAussie.

-

Im working on a bifold wallet and Im trying to figure out how wide to make the back so it is wide enough to fold. Its a verticle bifold with 2 card pockets (3 layers on each not including the back). The gap where the pencil is pointed, I currently have it drawn at 1 inch but I think that is too wide.

-

Currently I use the wing divider to scribe my line and punch my holes along those lines. I'm ok using both hands, I just find myself switching hands with tools which is normal for me outside of this craft. It is frustrating at times because some of the tools are not inherently ambidextrous. I know there are some groovers where the center post is the groover and the arm is adjustable. My groover is opposite and the arm is the groover so if I saw it for left handed use the groover is facing up lol. I need more practice and time on tools for sure.

-

I am left handed, but right hand dominant. I use my left hand for eating and writting, but I use my right for everything else to include shooting. When I'm trying to cut leather, neither hand feels wrong, but neither feels right either. Are there left handed tools out there like groovers? I bought a right hand groover and every time I pick it up and try to use it with my left hand it throws me all off lol. Do any of yall have experience with this or any suggestions?

-

How did you get into leather work?

MarkCdub replied to Rolandranch's topic in Leatherwork Conversation

My first completed project was a knife sheath for a small fixed blade gerber. I think sheaths are first projects for many because they are not as intimidating as a wallet or gun holster and don't generally take as much leather. My first project was a minimalist wallet/business card holder, 6 layers of 5 oz veg... Talk about a brick! I made my current wallet out of 1-2 oz veg a year or 2 ago and haven't had much opportunity to create since then. Job, family, family, etc take up all my time. I also don't have a work bench and it was difficult to work on a small kitchen counter and waking up babies pounding stitching holes gets you in trouble quick! Lol. I recently built shelving in the garage and am in the process of organizing everything. Once that is complete Ill be building a work bench for my hobby. I love the craft and I really want to get proficient at making wallets, notebook covers, checkbooks, and anything that falls into the Every Day Carry category. -

How did you get into leather work?

MarkCdub replied to Rolandranch's topic in Leatherwork Conversation

I've been watching your projects for quite some time (maybe since we both joined here around the same time if my memory is correct) but boy, you have had some talent since day 1 I remember seeing your projects. You could easily supplement your college funding with your work. Wallets, checkbooks, etc are relatively easy, quick and should sell quickly around campus. They aren't too expensive for college folks amd make great presents for their moms, dads, grandparents, aunts and uncles... Assembly line type set up and crank those suckers out!