ArkieNewbie

Members-

Posts

221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by ArkieNewbie

-

Duck Tote for Brother in Laws

ArkieNewbie replied to ArkieNewbie's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks, @fredk ! -

Best place to find 3-sided Horse Halter Squares

ArkieNewbie replied to RockingRA's topic in Suppliers

Don't know anything about the quality but, I found these...... https://www.zackwhite.com/34in-Solid-Bronze-3-Way-Halter-Square--H37012BZ_p_3051.html -

Duck Tote for Brother in Laws

ArkieNewbie replied to ArkieNewbie's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very cool! Never thought about fleas and rabbits. That's pretty clever. Do you clip it on a belt loop? -

Wallet for My Brother

ArkieNewbie replied to ArkieNewbie's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks! I appreciate it! I've worked hard on making my stitching at consistent as possible. I agree with you. Clean stitching makes all the difference in the world! I have two ostrich legs at home that I have been putting off doing something with. I've thought about a check book cover but just haven't been able to pull the trigger yet. Thanks! He was happy with it! He usually just keeps his cash and cards loose in his front pocket so a front pocket wallet fixed him up good. Thanks so much!! -

Duck Tote for Brother in Laws

ArkieNewbie replied to ArkieNewbie's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks! Yes sir! My thoughts exactly. We had discussed this on a separate thread and it only makes sense! Thanks! That's cool! A western coastal hunt is on my bucket list! Those sea ducks are super cool! -

Wallet for My Brother

ArkieNewbie replied to ArkieNewbie's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks! I appreciate it! I like the camo as well. It is La Perla Azzurra. From Rocky Mountain Leather Supply it is like $17/sf. I'm not to a point where I'm comfortable paying that so buying somebody else's remnants was a big win! -

Here is a wallet I made as a Christmas present for my brother. I bought a remnant box of high end leathers from a guy who makes really nice wallets and wanted to try it on one of my designs. I'm proud of this one mostly because of the progress I can see in it. I feel like my edge finishing has progressed really well. This is also the first project I have used my new maker stamp from Bunkhouse Tools on. I'm really happy with the stamp even though I didn't get a great impression on this leather. I pressed it before assembly but I think this leather was a little soft to take it really well. Anyways, let me know what you think!

-

@GrampaJoel , I tend to agree with @nstarleather on this one. I call my leather "business" Crowley's Ridge Workshop but my name is Justin. If I stamped Justin on my work I could see how some would take it as personalization. If it were me I'd just add the work Leather or something behind your name to make it more clear that it's your maker's mark. Just my opinion. If your customers don't mind then I'd say keep rocking the way you are.

-

Thumb hole sling

ArkieNewbie replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You're supposed to make these things AFTER your in the duck blind hahaha -

Any truth to the rumor that Weaver Leather purchased Ohio Travel Bag?

ArkieNewbie replied to YinTx's topic in Suppliers

I'm a credit manager at a steel mill and in my professional experience when private equity comes in and buys one of our customers it is all down hill from there. They will bleed successful well run companies dry to finance the operations of other ventures and not reinvest back info the once successful company. I buy hardware from OTB because of their quality. I'm holding out hope that it does not fall victim to cost cutting measures implemented by the private equity firm. Quality and service are usually the first two to go. -

Wow! Those look awesome and very comfortable!

-

Any truth to the rumor that Weaver Leather purchased Ohio Travel Bag?

ArkieNewbie replied to YinTx's topic in Suppliers

I just bought some buckles from OTB and there was a letter in the package announcing this. When I saw it I said, "Oh no!" My wife asked what was wrong....haha -

@Frodo that makes sense. I really appreciate you sharing this way of doing it. It seems a very clean way of making the pockets.

-

@Frodo I had to do some back flips inside my head but I think I finally got my mind wrapped around your genius idea. I've got some light weight camo canvas that I have had no idea what to do with. THIS may be its finest hour.

-

Thank you for pointing this out, that is a good idea. I work at a steel mill with a good fab shop so I be we can find enough scrap laying around to put something together.

-

@HBHays13 is this machine still available?

-

Thanks, Chuck! There's some good stuff there.

-

That's a good idea. I have been meaning to buy an arbor press. Harbor Freight has a 1 ton press for $64 and I think that would serve all of my purposes.

-

I thought about that but, and this may sound weird, they just look TOO good. That would certainly eliminate my problem though. I have used the precut pocket shapes from SLC and love them and will continue to use them for bifold and minimalist wallets just because they are clicked out so perfectly and consistently. I wish they made roper wallet precut t-pockets too.

-

From everything I just read about it, i don't see any reason why it couldn't be used to line a gun case. Sounds like it it breathable and soft so it won't damage the finish. https://www.thescotlandkiltcompany.co.uk/blogs/news/what-is-polyviscose-fabric

-

Thank you to all three of you! Very good info. @GrampaJoel @mike02130 @Danne , thank you for the visuals! You're option 3 is what I had pictured in my head. The leather I have for my pockets is a 2/3oz. veg tanned. I have a set of French edgers so skiving down the edges should be a pretty decent option. I'm not super skilled with them yet but I am getting better. Making belt keepers has helped me with my skiving skills. Would it be recommended to skive down the edges of my wallet back as well? I am using a piece of 2/4oz. Hermann Oak veg tanned for the back. I had someone order a roper wallet last night so this will be a good "trial by fire".

-

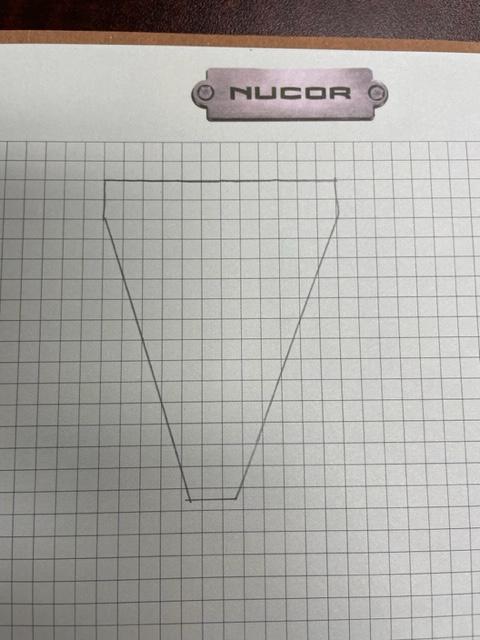

I just made my first roper wallet. It has 6 pockets down each side. The problem is that I have a big bulge in the middle where the majority of the pockets overlap. What did I do wrong? I have a potential solution of making "t pockets". I think if I make the pockets like the drawing below and then drop the next pocket down to where the first pocket angles in that should fix my problem. Am I overcomplicating this?

-

Waterfowl tote

ArkieNewbie replied to Gezzer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Next time Canada Geese are around you should try tackling one. It's kind of like a dog finally catching a car, you'll regret it real quick -

Waterfowl tote

ArkieNewbie replied to Gezzer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

100% agree with you! I also like that you made yours to hold 6 ducks. Almost all of the ones you see online hold 12 ducks. In Arkansas that's a good way to catch the AGFC's attention, something which I never want to do.