Search the Community

Showing results for tags 'clutch'.

-

Does anyone have any suggestions for slowing down a Consew machine. I have reduced the size of the drive pulley as small as is possible. when sewing, the machine seems to lack torque to start, so you require lots of pedal, but then the piece takes off. Once you're sewing it is easy to throttle the machine back to a creep with delicate manipulation of the foot pedal. does anyone make a larger handwheel for these machines. I know sailrite makes one for their machine. It occurred to me to machine a 2 part pulley/disc/donutish sorta thing that could be bolted onto the existing handwheel, but I don't want to reinvent...the wheel!!!! Thanks, brent

- 2 replies

-

- clutch

- consew 206

-

(and 1 more)

Tagged with:

-

Started this project last year as my first Clutch for the shop I sell out of in Santa Barbara CA. During the C19 shut down I focused on completing a short run of 4 bags of which I've been able to salvage three. The 1mm Herman Oak outer as well as all intetnal pockets are lined with .5mm Italian Lamb skin in black or in one case red. The bag features a front zippered pocket, a magnetic flap fastened center pocket and a 3 credit card holder on the back inside wall. End gusets are nylon lined and feature eyelets or D rings to accept an optional wrist or shoulder strap. Selling starts at $175.00. I've produced 10 like these and the design continues to evolve through interviews with my Test Drive Staff who carry, use and report on what they find wrong or in rare instances what they find right! My instructor suggests I start with big and work small as this is more typically an easier strategy for successful beginning bag making. Now he tells me. I designed the 12 patterns by hand and not including thread combine 22 separate components that takes me about 24 hours each to assemble. Not a big money maker. Most of the stitching is done using #69 thread on a Juki 1541S or a Cowboy 335 but I also use a Techsew 5100 for sewing the center pocket into the gusset folds with 138.

-

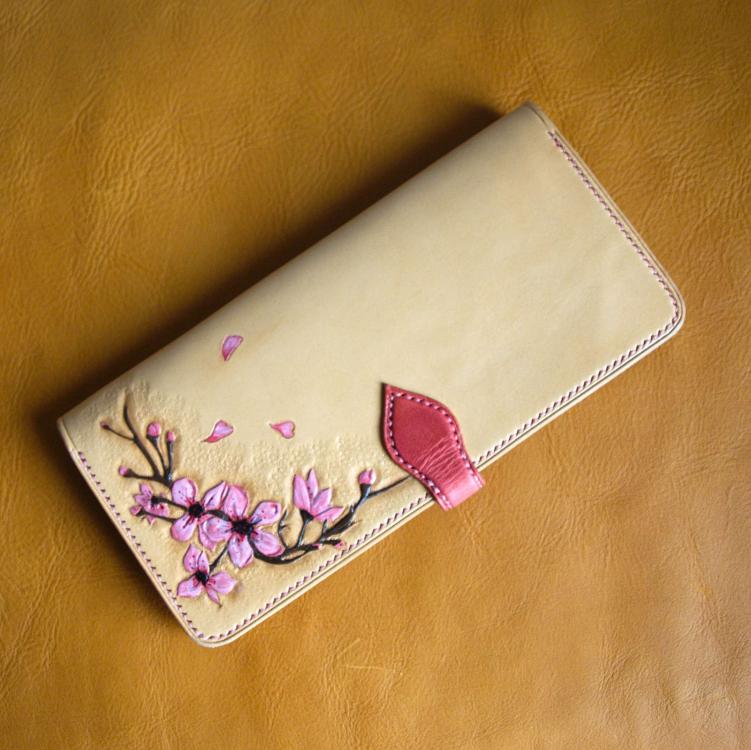

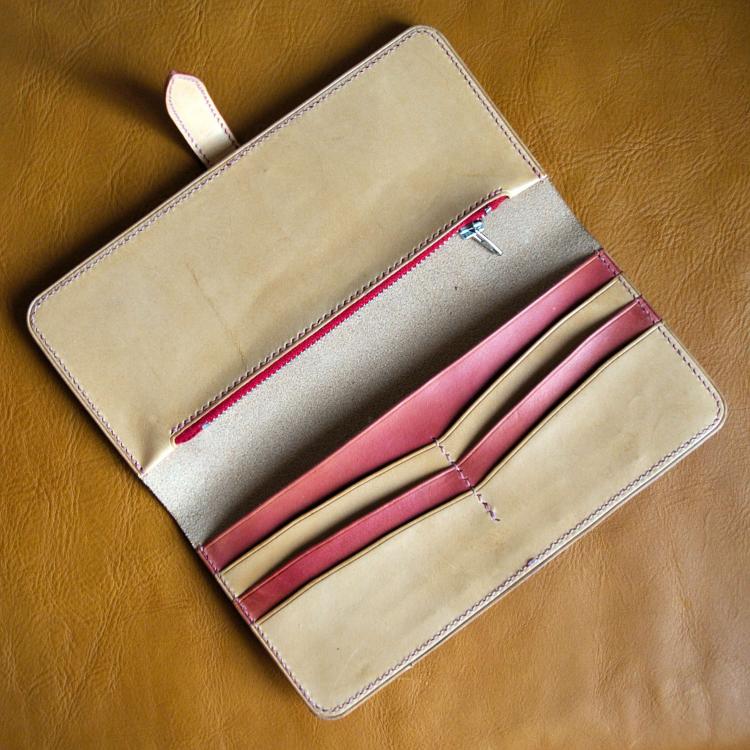

with a spring vibe. The size is 25x18x5 cm, one single compartment, snap closure. Materials used: -2 mm thick vegetable tanned leather -Angelus paints for the tooling -Pink Polyester thread

- 25 replies

-

- cherry blossom

- natural

-

(and 3 more)

Tagged with:

-

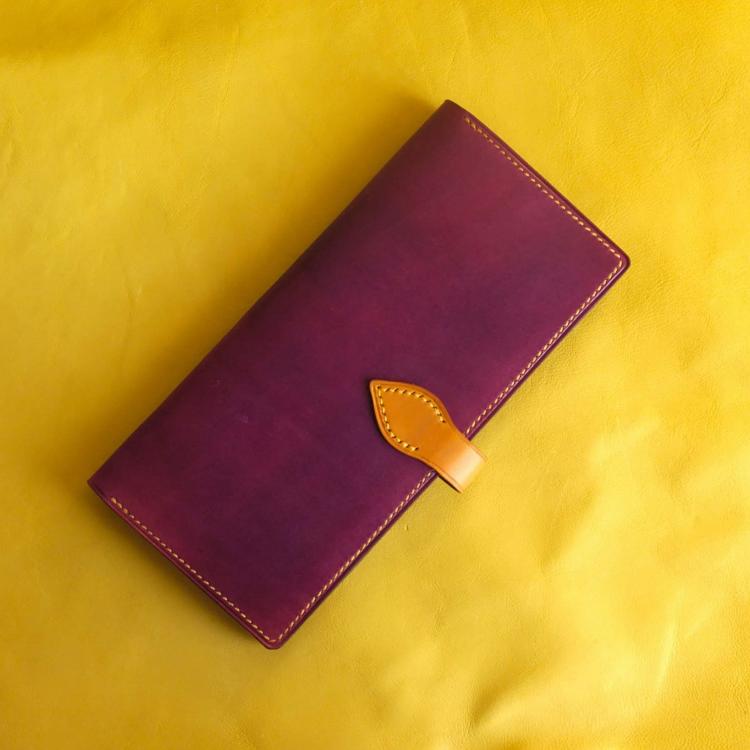

Pink Floyd themed wallet I made as a commission. The original drawing I found on google. Details: -2 mm veg tan for exterior, dyed with ROC leather dye, violet color -Angelus paints for the tooling -1 mm veg tan for interior -Yellow Wuta thread, 0.45 at 3 mm spacing

-

Hi. This is my first post so let me start with a brief bio. I'm 64 and plunging into a long time interest in upholstery work as a hobby. I started by buying a machine before I had learned enough to know exactly what I wanted as perhaps many do. That has led me to more googling and landing here. :-) I bought a Singer 211A157AA Needle Feed machine thinking it would perfect for my intentions. I have used it successfully making a piped cushion for a window seat and replacing the fabric on two Sling type lounge chairs. But I found the needle feed to be less than satisfactory when it comes to holding the material when feeding. I stumbled onto a Consew 226 that needed some TLC but I was able to get it relatively cheap at $200. After some cleaning, adjusting, and oiling I put it my power stand and it sews just great. With the Consew was included a very old looking stand with a motor and separate clutch. It actually works but I haven't given any attention to it yet. I would like to ask you guys if it has any value and is it worth the elbow grease? I can't find a single reference to this type of clutch for sewing. Any info would be appreciated. Regards, TerryF

-

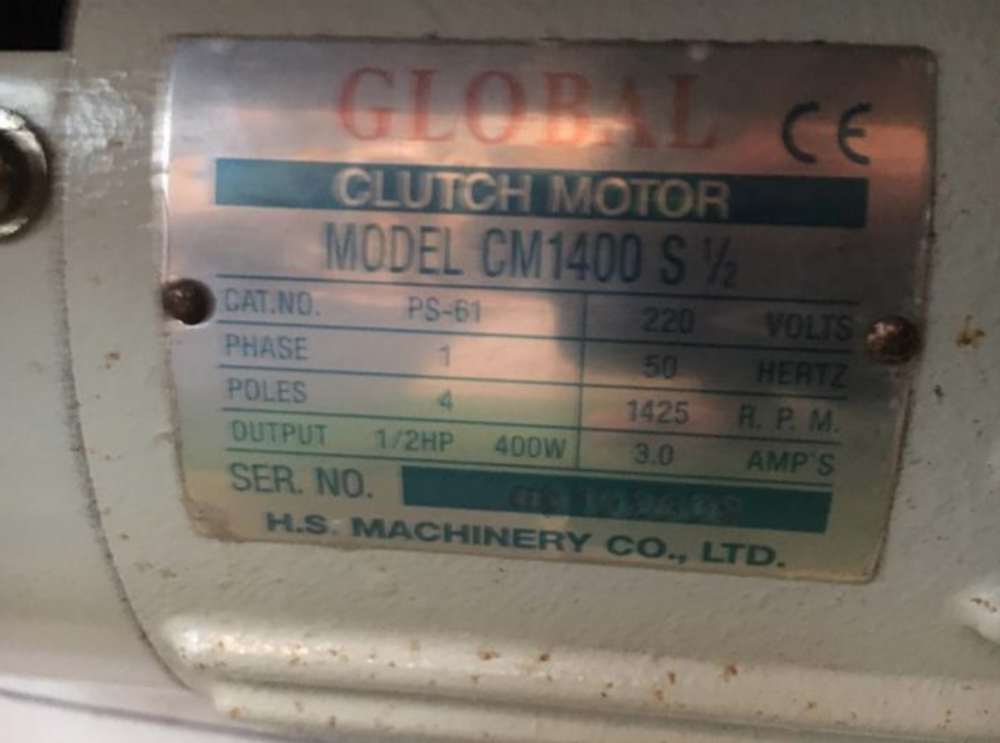

I'm in need of a 'slow' sewingmachine for precision and control stitching and found a good deal now. The advertiser send me this photo of the motor; it's a clutch motor, he called it a 'leather motor' since it goes at about 1425 r.p.m. I have no experience with motors/electronics and could use some advice regarding this offer, or deciding to upgrade to a servo. I made the agreement that I can either buy the machine without the motor (and order a servo elsewhere) or buy it with, but it will have an impact on my budget. Will this motor be slow enough for my needs? I would like it to go stitch by stitch at times, I'm not at all interested in 'fast' options. Also I prefer the machine to be quiet, which I know a clutch is not. What is the aprox. value of this clutch motor (without machine)? Thanks !

-

From the album: Dogwood Grove Goods

Tolled leather ladies clutch -

My second iteration for this bag, this time bought by somebody on etsy, the first was a gift for a friend. 2mm italian veg tan for body, 4 mm for strap. Turquoise dye from Fiebings for bodyand Angelus paints for the wave.

-

Made another variant for my cherry blossom wallet, this one is nicer I think. The stitching is at 3 mm spacing and the closure is a bit more delicate.

- 14 replies

-

Hi there I made a simple leather clutch. I used an Italian vegetable tanned leather and a small stud-closure for a metal part Thickness is 2.3t (6oz) Making film & pattern >>> https://youtu.be/UK2BXHcM5JM Many thanks!

- 7 replies

-

- clutch

- italian vegetable tanned leather

-

(and 1 more)

Tagged with:

-

I scored an old walking foot Singer 16-188 for next to nothing and it works fine, but I believe clutch needs some correcting. At first it would shake whole table every time you engaged and would not grab at first and then at full speed. It improved a LOT after I cleaned the clutch plate and pad and made sure they were actually parallel. I still think the pad may need to be replaced, though. But can't find the right size and thinking of just making one. So I have several questions: 1) The current pad is leather, but I see all the replacement ones are cork. Do I have to stick with leather? Is one better then the other? 2) The current pad is leather and is soaked with oil. Is that just accumulated over time from drips or is it actually supposed to be oiled? 3) To make my own is there any reason I can just use any think vegitan or oiled leather? (is one preferred to the other?) If I use cork, can I just use thin cork pad I buy at local hardware store? is it special?

-

Can you help with a problem I have with a Juki LU 563? The clutch does not re-engage the main shaft after resetting the clutch ( I cannot sew). I have tried pressing the right button while turning the belt drive wheel, in the opposite direction ( away from the sewer) according to the instruction manual. The wheel seems to be locked when pressing the button and does not correct the problem. In addition the the stitch length mechanism disengages the clutch each time I try to change the stitch length. Thank you in advance.

-

Sneaking in another project for myself before honoring my promise to hubby to make him another watch band for his Apple Watch (I think he’s getting a little spoiled, but it’s how I justify the leather stash ). This one will be the same design as the last clutch prototype, done this time in a mink-colored Nile croc. From memory, the croc hide was about 32cms wide, grade I/II, in a Millenium (matte) finish. Will be lining with some incredible olive HAAS calf (thanks @nstarleather!), with hardware from Ohio Bag Supply. Stitched in Lin Cable 532, with KS 3.00mm irons. First step was that terrifying moment where you have to make the first cut . Luckily all went well, and I managed to get all the pieces out and still have nearly the full tail left.

-

I did 3 things to slow ny old clutch motor 1. Installed a 1 1/2” pulley on motor 2. Lengthened the engagement bar by 12” 3. Made a New 6” Hand pulley for the machine from hard maple This increases the gear ratio and maximum speed is now 1/2 of what it was If you have a lathe this is very easy to do I’ve made several for friends and they all love em’

-

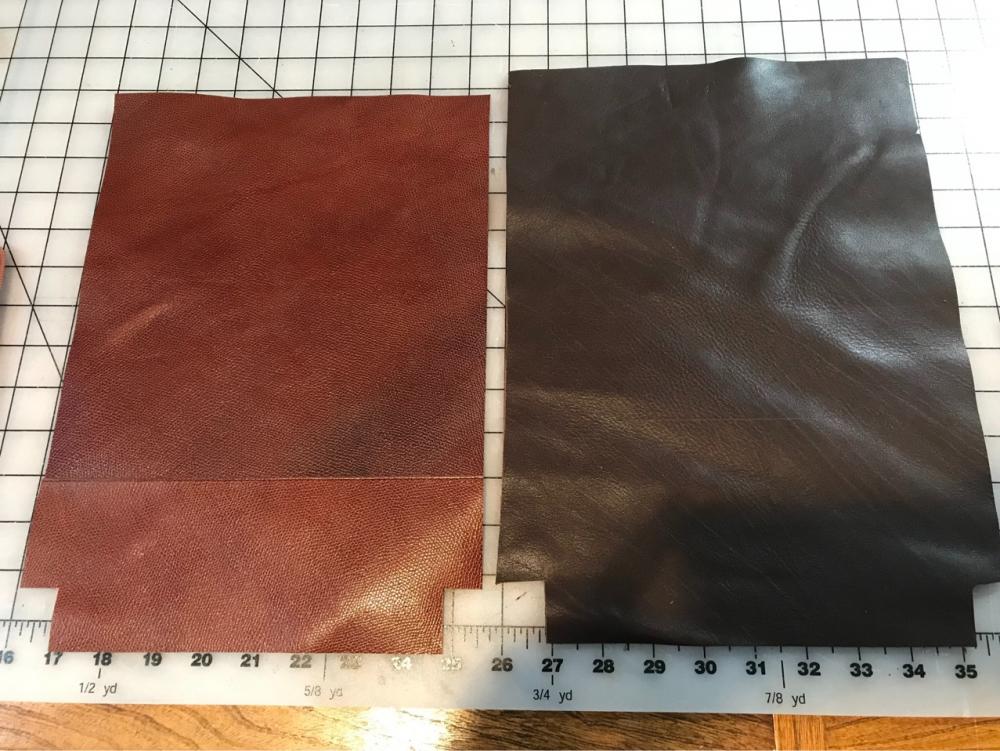

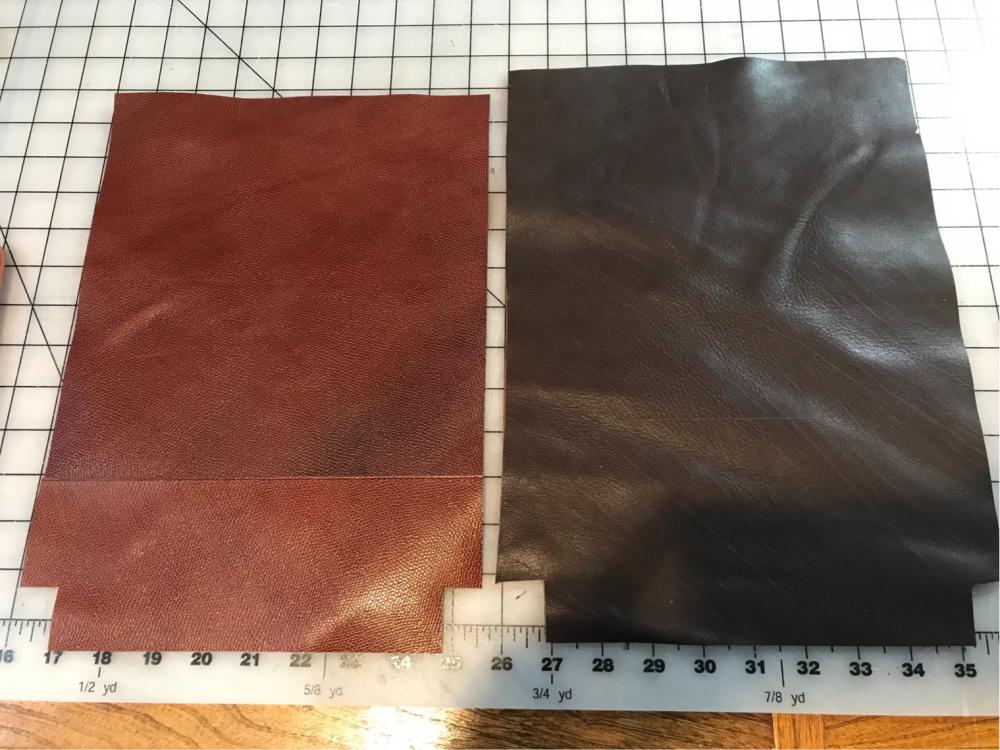

New project in the works. Have a croc skin I want to make into a purse, but figured the smart thing to do is to make a prototype first out of some rather less expensive pebbled calf, lined with dark chocolate HAAS calf leather (thanks @nstarleather!). I’m heavily inspired by an, ahem, certain luxury goods brand, with hardware from Ohio Bag Supply (through hardware elf). Stitching irons are KS 3.0mm, thread is 532 light brown Lin Cable, and trying out the Renia Aquilim glue for the first time. Bag width is approx. 24cm. Will post more photos as I progress.

-

Hi guys! My name is Kristi and I'm from Tundra Leather in Hamilton. Here's a link to our blog post on creating a simple and easy leather clutch purse. This is a beginner project and great for getting people interested in leatherwork. Work's well for a birthday party, or girl's night! Click Here for DIY Clutch Purse Instructions Feel free to send us a message or email (info@tundraleather.ca) us if you have any questions! Have a great day! Kristi

-

Hi guys! My name is Kristi and I'm from Tundra Leather in Hamilton. Here's a link to our blog post on creating a simple and easy leather clutch purse. This is a beginner project and great for getting people interested in leatherwork. Work's well for a birthday party, or girl's night! DIY Clutch Purse Instructions Click Here Feel free to send us a message or email (info@tundraleather.ca) us if you have any questions! Have a great day! Kristi

-

So, staring a prototype for a small clutch (eventually going to do in croc). Pic below shows outer and lining. I’ve glued the lining completely to the two side gussets, but I’m curious if the lining gets fully glued to the main body, or just close to the edges where it’ll be stitched? Also, how do you account for the turn when the main body is folded; do you simply make the lining shorter than the outer, if you’re not completely gluing the two together? Thanks!

-

I haven't made anything in a while and never real post much so here as a small leather clutch I made over the holidays. Still learning everyday and getting better at stitching going to be buying a industrial machine soon. I love the hand stitching for the strength and look but it's just so time consuming.

-

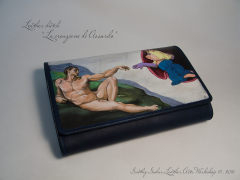

Leather clutch La creazione di Assurdo

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

Material: leather Size 8,3х5,1 inch Theme for the painting selected by the customer ... the concept has turned out so provocative that we just could not resist :))) "Stuffing" no surprises - there are three main sections; zipper pocket; 6 card socket under the cover and 4 small pocket on the front wall (inside). Closed with magnetic button. Do not hesitate to ask! If you want us to something like that, you can always contact us - Etsy