Search the Community

Showing results for tags 'help'.

-

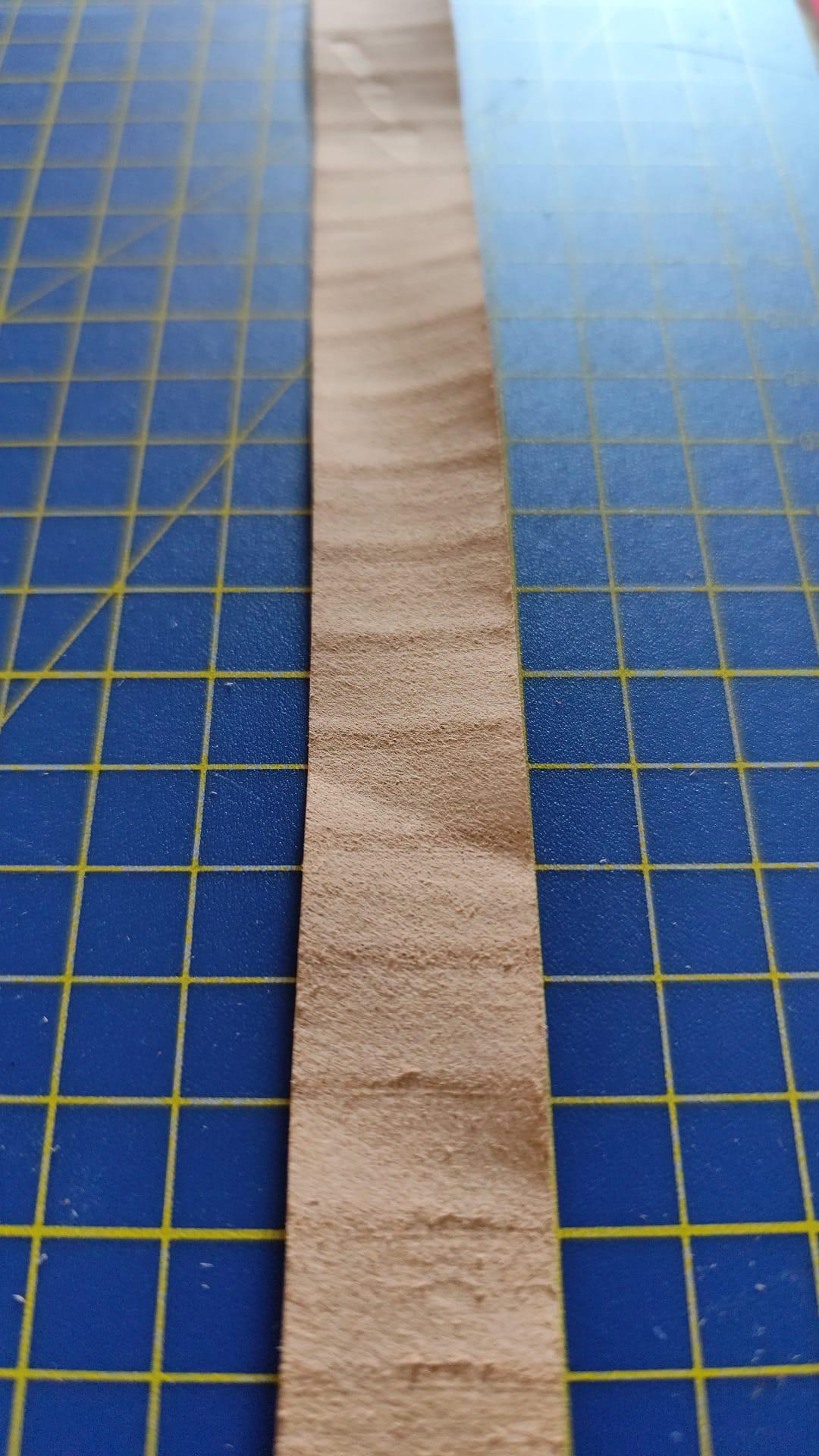

Hello everyone, I recently bought my first skiving machine, it's a used machine, a Sagitta SC75A (for which I'm also looking for the manual) I'm new to skiving so I'm asking you if you've encountered problems like mine and could you explain to me how I can solve them? The big problem is that it flakes unevenly with a wavy pattern, not smooth as it should be. Thank you Ps, I'm attaching a photo to help you understand the problem. It's a 2cm wide and very long strip of leather, stripped from 1mm to 0.5mm.

-

Ciao a tutti, ho acquistato da poco una scarnitrice usata (Sagitta sc75A). Ho notato subito che la campana della lama vibra molto, tanto da compromettere l'affilatura. Ho contattato quindi il mio meccanico di fiducia e pensando di risolvere ho fatto cambiare tutti i cuscinetti, purtroppo non ho risolto e rimane una leggerissima vibrazione. Il rumore è sparito, i vecchi cuscinetti erano rovinati ma purtroppo non ho risolto completamente. Cosa mi sfugge? O cosa sto sbagliando? C'è una vite sotto la macchina che può aiutarmi a eliminare questa vibrazione? O cosa dovrei controllare? Qualsiasi consiglio sarebbe utile. Sto anche cercando il PDF del manuale d'uso di questa macchina. Grazie per aver letto questo e grazie se risponderai. PS la macchina è stata pulita da tutto lo sporco, ingrassata e oliata correttamente, ho fatto qualche prova senza la lama ma la vibrazione rimane

- 1 reply

-

- skiving machine

- problems

-

(and 1 more)

Tagged with:

-

fur sewing machine Fur sewing machine information.

Sammetje999 posted a topic in Leather Sewing Machines

Dear leatherworkers, Some machines are just ment for a select group of people because it's not something you use every single day unless it's your job But that doesn't mean there has to be a shortage of information about it. I will tell my experience with a fur sewing machine so that I may help others. About a month ago I bought a Allbrook & Hashfield fur sewing machine. They told me it was serviced but it didn't want to sew properly. So I started searching and searching but I couldn't find a lot of information. Not even proper manuals. I found lots of videos of people using it but non of them where useful for me to tune and service my machine. After a lot of research and looking at my machine I didn't want to wait any longer. I was going to service it myself and either ruin it or fix it. First of all my machine uses Schmetz 459R needles. Also called EB X 1567. I found that the looper arm was to high and not in the correct placement with the needle. So I loosened the needle bar and took it a bit backwards. I also loosened the looper arm and put it a bit forward. Now it was in the perfect location, just before the eye of the needle when it came back (just like on a sewing machine with shutter hook). So now the height of the looper arm. I inspected the machine and saw 2 bolts. I loosened them and now I could move the looper arm up and down. I carefully put it about half a millimetre about the needle plate and tightened the bolts. Now I was ready to try to sew again. And low and behold. It worked! I would like for everyone to out down information they have about the fur sewing machines. Doesn't matter if the models or brands are different. Maybe someone will find it useful. I will put some pictures from my machine to show what I loosened and tightened. Hopefully someone will find it useful. Kind regards, Sam T.- 16 replies

-

- fur sewing

- help

-

(and 3 more)

Tagged with:

-

Hello all! I haven't really posted on here before, been more of a lurker haha. Recently, while I was at work, a man came around selling some tools and leather that he had extra. I'm fairly new to leather working (about 7 months), but I have heard tell that some tools are better quality than others in the long run. I have been anticipating a chance to get some better tools so when he pulled out some punches that are branded "AS BRAND" and an "Al Stohlman" belt punch, I quickly offered to buy them as I recognized the name. In heinsight, I should have inspected them a bit closer. A couple of the punches are damaged (See pics). I can't find any information on them online and was hoping someone could fill me and let me know if they can be fixed and/or if it would be worth while. I'm kind of leaning on; I should have looked closer and passed on them but hoping I can still get use out of them. The fact that they are already damaged and I can't find any information on them does not give high hopes for the others. Any information is greatly appreciated. Thank you (:

-

Hi all i need some help using a usmc splitter model A . I watched a video and found the manual but still cant get the leather to feed properly. It either goes above or under the blade. Hopefully someone knows something about thos machine i would like to bring it back to life.i am feeding veg tan 9 to 10 ounce. IMG_20250103_185121.heic

-

Hi all, My dad was a leathersmith for 40+ years and amassed a small factory's worth of machinery, tools, materials, etc. I grew up helping him in his shop and gained an appreciation for the craft. His specialty began with shoe/saddle repair and ended with belts. At his peak he was selling to LL Bean and several other notable places. Sadly, he passed away last year after a long battle with cancer and I inherited his remaining leather business with no documentation. I have taken a different route in life and am now looking for guidance for how to best approach sorting through things and liquidating. I thankfully don't have any timelines or deadlines to deal with but it would be great to be finished in about 1-2 years. I'd like to approach selling items with respect for what he collected and to find the balance between treating items fairly as inheritance (which will be split with family) while also being generous. Unfortunately, the leather business is intermingled with a wide variety of other items he collected/hoarded, making cataloging the entirety of the items essentially impossible. I do have knowledge of what many of the items are (except some of the hand tools) but next to no knowledge (without research) for what items are actually worth. Links for pictures are at the bottom for a rough idea. Where possible, I'd like to avoid the scenario of selling items to the parties informing me of the value. It's not that I don't trust people, but overall I don't think that approach is necessarily wise for anyone to take (plus I don't want to feel dumb). All that being said, my general thoughts on how to approach this task is to start with machinery and then separate remaining tools/materials once more room is available to organize. I figure the machinery takes up the most space and is probably the most straightforward to sell. I probably need to start a spreadsheet with major items/model numbers/etc. I would be able to compensate someone knowledgeable (with cash and/or items) for assistance in this overwhelming journey I've found myself on (I'm located in western NC, USA). Does starting with the machinery sounds like the best course of action? I might make a single post with just machinery with model numbers/etc for help identifying items/pricing. Any advice or guidance is sincerely appreciated! Pictures: Machinery: https://drive.google.com/drive/folders/1cAMMJHLHLwIatfd6NWshuhtOKhmNizzW?usp=sharing Tools/materials: https://drive.google.com/drive/folders/1G9RfW8Y20XO3B92jhouMHvOa1S9L-yaG?usp=sharing

-

I am trying to make a keychain with an old silver half dollar on it I'm not to keen on brazing a post or threads on the back as it would deeply wound me to deface a beautiful piece of history. So I had the thought to make a simple key chain that's all one piece and folded over with a cutout for the coin my only issue is how to properly mount it. So in summation I would have a keychain that is bigger than the coin with one of the two layers of leather cutout to fit the coin into. Thanks for any help and advice. ~Josh

-

(Link to video of bag im planning to make) https://www.youtube.com/watch?v=jH09RV1JqgY&t=657s ( Hi. I have been planning to make this bag for my wife this Christmas, however it is the largest project I have made up to date to this hobby and would like some insight on recommendations for how and where to add stiffener and lining to this bag. Im planning to use a 2.5-3oz chrome tan, peltex 71f stabilizer, and pig suede for lining However, I am not sure as of yet what specific areas to add the stiffener (if I should just cover the whole bag with it, the whole leather cutout panels, etc.) and the same with the stiffener I would love to have some insight from some people more experienced, and attached some screenshots of the template below for more context. Template pictures:

-

Hello, i recently bought a Singer 18-2 machine, and i need to change the two screws on the wheel bar (i'll post a picture of which ones). I bought the screws used for the seiko tf series, however they're too big. I found a parts list for the singer 18-2, but it doesn't mention the size of the screws or anything that can help me to track it down.

- 5 replies

-

- replacement

- parts

-

(and 3 more)

Tagged with:

-

I just bought this Singer 111w113 machine from a guy in Ohio who said his son used it for years making Corvette covers. It was serviced within the last few years and apparently runs great. Well when loading it into my truck, the guy dropped it and it hit the ground hard. He assured me it was fine, but when I got home I discovered the extent of the damage. The flywheel had broken from how it landed during the fall. I've seen replacement flywheels online, but the problem I discovered was that I couldn't adjust the stitch count, and it seemed to be stuck in its highest setting. Upon further inspection, it looks like the shaft the flywheel sits on has bent and also the threaded part has cracked. I can't figure out what this piece is called, or how to find it. I've checked some online retailers and even PDFs of original instruction manuals, but I can't find how to get a replacement for this piece. I hope someone is able to identify what I cannot. Thanks in advance!

-

Cobra class 26 thread tension knobs/adjustments

DieselTech posted a topic in Leather Sewing Machines

Guys & gals I finally got my cobra class 26 up & running. I have a question regarding the thread tension knobs. I watched Al Bane thread tension adjustment video & I can't tell in the video which knob he is adjusting. There is 3 knobs. I think he adjusted the big black knob in the center. My top thread is looping on the bottom, telling me to tighten my top tension. Can somebody tell me which knob to adjust 1st? Also the silver knob is completely loose. What does it control. Is that some type of fine thread tension adjustment? Should the silver knob have some tension on the spring that is behind it? Thanks any & all help will be greatly appreciated. -

Hello. I’m almost finished with a project. I tooled, painted it and then applied Tandy Hi-Lite Briar brown. I realized it didn’t fill in enough shaded areas. I want to paint over the hi-lite now. I haven’t done this before. Can I paint right over it? Do I need to sand it first? Will it wipe off overtime? it’s going on a firefighter shield so it maybe be exposed to heat and water. thanks in advance.

-

I’ve been a long-time stalker and now a first-time poster and have to say I am very grateful to be able to read other posts I was able to figure out ways to get out of a jam whenever I was stump working on a leather project(s) thank you So now I am looking for someone local here in the Summit City that can help me appraise some the extra leather tools that I have doubles of even some triplicates. And possibly show me what to keep, I'm trying to downsize everything I have not only because space is limited but also because my disability is starting to affect me more often so if you are local please let me know, thanks Thank You for your time And God Bless

-

Came across this old sewing machine, the owner wants $150 but I have no idea what model it is or if its suitable for leather. Any ideas?

-

Help, Singer 12w10 and 16-137 for chrome tanned?

Francesco posted a topic in Leather Sewing Machines

Couldnt find any information online regarding this two machines, can they sew 4 - 5 oz chrome tanned, crazy horse? whats the maximum needle / thread size I can use with them? The owner wants $130 for the 12w10 and $220 for the 16-137 They are also ofering me this one for $220 they only know its a singer, but not the model, any help identifying it? Which one is the best option, or none, of the three? Any guidance and help will be greatly appreciated. -

Hi, everyone! I’m looking to make a corset that someone would like in white. What are the most effective and efficient methods to getting the leather even? Is there a way to dye the leather? I had someone recommend diluting paint, like Angelus, spraying the leather first, then painting over it to get an even surface. I also heard that spray painting the leather can get a nice even coat without the streaks of a brush. Thoughts? Thank you!

- 8 replies

-

- painting on leather

- help

- (and 9 more)

-

Guys & gals I recently recieved a new cobra class 4. I would like to install the #25 needle plate & feed dog. What adjustments need to be made? Is there a actual # for the feed dog height above the needle plate? Videos I watched said a papers thickness above the needle plate is the proper feed dog height. Can somebody give me some pointers to make sure everything is ok & I'm not going to break something. Thanks.

-

Guys & gals I'm assembling my cobra class 4. Where does this screw in thread guide go? It was in with a bag of parts. I cant seem to find anything about it. Now lmao I havent looked in the manual yet for it. I found 1 spot on top of the sewing machine it threads into, I just dont know if that is where it goes. The other thing is, if it is used what's it used for? & how is thread routed thru it? Thanks.

-

I thought i had it under control, but I am in desperate need of help. Its a cardholder. I dyed it black (sprite-based dye, 3 coats), let it dry over night, buff it, applied satin sheen (two coats) and buffed it (no dye is coming of). But, when I buff it with a wet cloth, the dye comes off. I cant have the dye coming off, it will ruing the clothes. What I am doing wrong? What I am to do? How can I seal this? I have leather grease, satin sheen and Resolene at my disposal. (I try to avoid resolene due to the shine it gives) This is my first real commission and I really want it to be perfect, and I am suppose to ship it out tomorrow! Any help is deeply appreciated! /Nicklas

-

Need Problem Solving - Bending Decorative layer on Quiver

DavidK posted a topic in How Do I Do That?

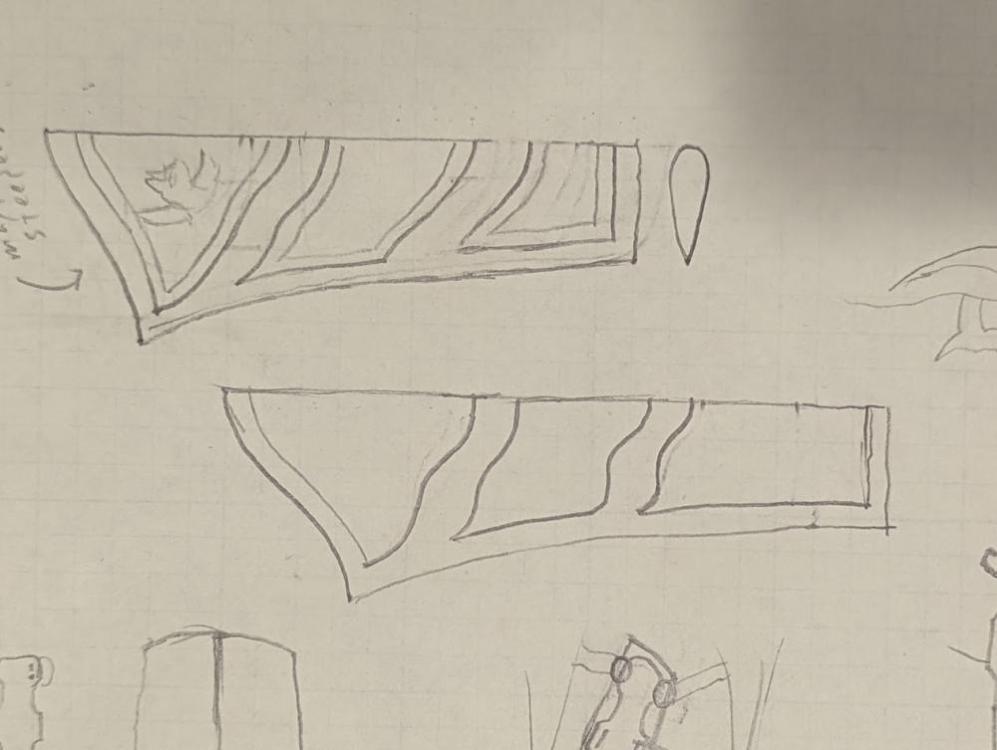

Hello, As an experiment im making an archery back quiver, and anticipating a problem. The pictures hopefully will make it more clear. I plan to attach these 3 5oz decorative panels to this 8oz quiver, the quiver will then fold in half and be stitched on the long side into a quiver shape. The anticipated problem will be that after stitching the panels on while the quiver is flat, the panels wont allow the quiver to then fold into the taco and stitch into final shape. Any suggestions here on how best to attach the panels, or if a product like shoe stretch leather could help (after attaching, maybe leaving a section unstitched to stick a dauber into the back of the panels and work it into the flesh side? Any suggestions appreciated, big, small, or project breaking Thanks! David -

Hello good people! I'm kinda new to this and was looking for helpful information which led me to this page, so I'm hoping someone with more experience here can help me! I made a few smaller projects up until now but wanted to try and make something bigger this time: the bag in the pictures. Sadly I'm not quite sure what type and thickness of leather to use for this project? I read that cowhide / calfskin is mostly used in making bags, would that be a good option here? Since in my mind the bag needs to have some kind of stability to it and from my experience cowhide seems to be kinda soft? Also which thickness can you recommend for a project like this? Since again in my mind it needs to have a firmer body to stay in shape and not get distorted while wearing it. I hope somebody here can help me and I'm thanking everybody who answers in advance!

-

I have the chance to buy an Adler 269, efka motor with automatic options for a really good price, the only problem is that the efka comes with a 3 phase socket. My question: will there be any difficulties converting the motor for home use, since theres electronic functions involved. Thanks alot for your help or suggestions

-

Guys & gals I'm wanting to try & line a wallet with sheepskin or goatskin. This stuff is soo thin, I'm curious what I need for glue. I surely cant use contact cement on this type stuff can I? If somebody wants to give me some tips i would sure appreciate your input & knowledge. Also what is the best way to finish the edges on a lined wallet? Thanks.

-

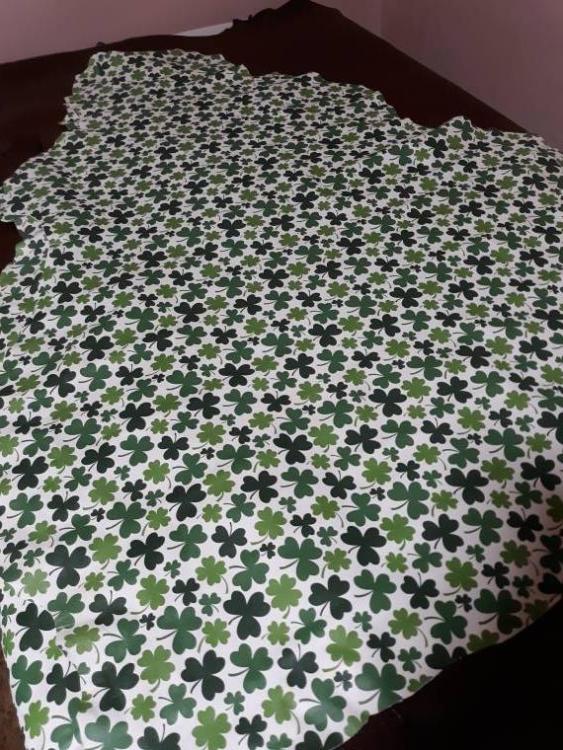

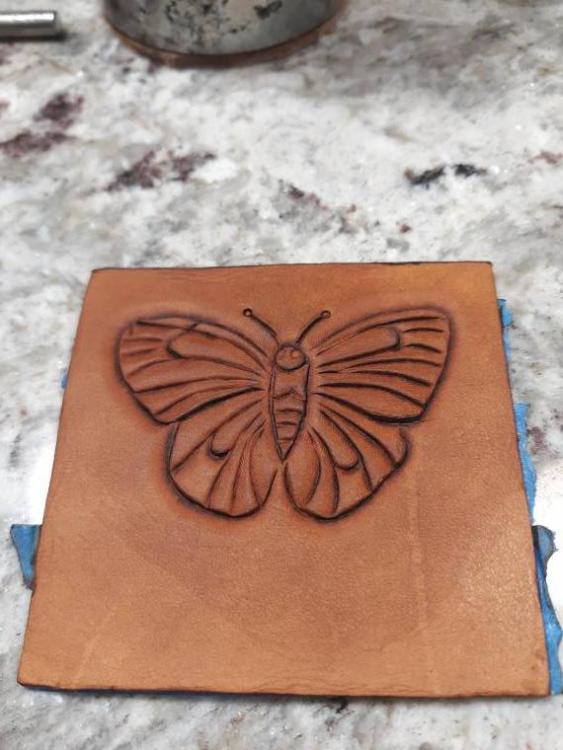

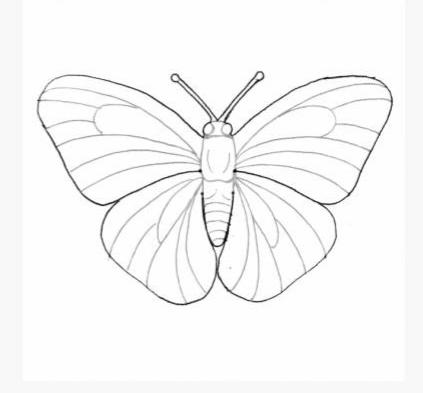

Guys & gals dont laugh to bad, but I'm trying to learn & teach myself figure/floral carving thru reading & videos. Can any of you professionals give me a couple pointers on carving a butterfly? I'm trying to do a coin purse for Christmas & would like to carve a butterfly on the back of it. Thanks any & all help/pointers will be greatly appreciated.

-

Guys & gals I'm curious as what I can use for wallet linings, clutch wallet & purse linings & projects of such? A lot of guys recommend veg tan kangaroo or goat skin. Well kangaroo is a bit out of my price range at this point. I was thinking about veg-tan calfskin for my linings of projects, or even sheepskin. Can some of you professionals give me some advice/direction to go. I mainly only use veg-tan leathers at this point for my projects. I was thinking veg-tan calfskin would be tight grained & also would dye well. Thanks any & all help would be greatly appreciated.

.thumb.jpeg.45ec98686445b6dc11866fc224ce19e0.jpeg)

.thumb.jpeg.7eced81d18e2613c4d45aa75ff4ca603.jpeg)