Search the Community

Showing results for tags 'patcher'.

-

Hey Folks, Managed to pick up a Cobra Class 29-18 for just $920 today. Pretty excited, I've been looking for a Singer 29k for months and just had to snatch this up. Anyway, I know there are folks on here that swear by their patchers and I'm looking for you folks to drop some of that knowledge. I have a Cobra Class 4, so this will not be pushed very far. Likely just wallets and boots/shoe repair. I'll likely have to file down the teeth since these impressions are SHARP, but aside from that.. I currently don't have thin enough thread for this machine (#69-#138) but I did thread it up with 207 and it faired pretty well considering it's outside the suggested limit. I'll be picking up some thread tomorrow, what would you folks recommend? As far as patchers go, should the bobbin thread be smaller than the top? #138 top and #92 bobbin?

-

I thought I would use this machine a lot more than I do. I just don't, so I'm selling it. Asking $2,500.00 Located in Santa Fe, NM. Buyer would either arrange pick up or pay for shipping. Phone is 505-501-1251. Anne.

-

Finally finished up this Caiman/oil tan roll top backpack. Original pattern called for hand stitching the entire thing. No thanks. Stitched entirely on my 29-18 patcher.

-

I just picked up an IMMACULATE Singer 29k-71 and the feed foot won't pull the work through. If I pull it, it goes to the appropriate length and stops, but there is no power going to make the foot pull the work through. Any help is appreciated. 20240414_152612_1.mp4

- 6 replies

-

- singer 29k71

- patcher

-

(and 1 more)

Tagged with:

-

Howdy all, I’m new to leatherwork and very new to sewing machines. I recently bought a cobra/singer patcher clone from Amazon (INTBUYING Industrial Leather... https://www.amazon.com/dp/B08HRLS3B7?ref=ppx_pop_mob_ap_share ) I got the thing all dialed in last week and sewed a belt with it. Seemed to work well and everything but when I got to the end it kept breaking thread. Thought maybe I over-tightened the top tension so I loosened it but it still keeps breaking. Now it seems that it’s missing the bobbin thread altogether. However when I don’t have material on the machine and I have the cover open I can watch the shuttle catch the thread but as soon as I slap some leather down it won’t. Can’t think of why it won’t work for the life of me and I can’t find any answers anywhere. Any help greatly appreciated, thanks in advance. Chase

-

Found this for an incredible CAD$800, came with 4 spare shuttles. Seems to be in good condition, looking forward to playing around with it. The only thing I see that is missing is one of the little thumb tabs to rotate the foot. Maintenance-wise, I think it just needs a good oiling. Shoepatcher, any hot tips?

-

Hello, I'm based in the UK and I have been looking for an industrial patcher: global 9929, Pfaff 8346, techsew 2900L, Claes 8346, type of machine. I don't need a motor as the electrics are different. I would need freight over to the UK, so it would need to be well packed It does not need to be new, I'm fine with a used as long as in working condition and no issues. Maybe there are other members from the UK on this forum and have some insight of where I could possibly find one. Thank you.

- 2 replies

-

- for sale sewing machine

- looking to purchase

-

(and 1 more)

Tagged with:

-

I knew I’d do something with these scraps someday. Pushing 40 years later, but I kept my promise. Scrap purse. No plan or reason.

-

-

-

I just got this, it’s missing the leaf spring/foot tension bar, I put a little hmm screw from a 31-30 in the stitch adjuster thing. it was cycling until I opened the bottom and the gear fell out and the small notch piece. I also took out the bobbin/shuttle, now it stops like it’s hitting, I don’t know what’s stuck. hopefully it will work, I’m sure I’ll need that spring to see though , anyone have one, or some tips ?

-

Just some pics of my process. A lot to explain, but hopefully someone interested in learning something new can take something from them.

- 2 replies

-

- exotics

- snapping turtle

-

(and 3 more)

Tagged with:

-

I recently picked up a Chandler c-2971 Patcher that's missing the bottom bobbin. Having a hard time finding parts for this machine, could really use some help.

- 1 reply

-

- sewing machine

- chandler c2971

-

(and 1 more)

Tagged with:

-

Looking for some help please. I have bought an old Singer 29K171 and is busy taking it apart and cleaning it. Replacing parts and bringing it back to life. But I have hit a snag. How do I remove the pin which holds the shuttle driving cam gear. All parts of the machine is badly funked up. Wd40 has helped and all other pins slipped out. But this one is stuck and I am not sure if it is meant to release to one side only.

-

I regrettably popped out the entire bobbin ensemble. I put it back in as best as I could remember it and was able to sew away for a while. Now, the upper thread keeps getting caught in and under the bobbin. I must have put the three bobbin parts back in incorrectly. Everything else is unchanged and looks okay. What is the name for the piece I am holding in the picture? The one I wish I never took out of the machine.. Can you tell me the correct orientation of this piece, and thus the bobbin basket, while the needle is at its highest position? The needle reaches its highest position on my machine when the handcrank is at exactly 12:00. Where should the crescent on the piece in the picture be at this point? If you could provide a photograph, that would be extremely helpful!

-

I find it amazing how things come in waves. I am still getting my 45k in order when an opportunity to buy a 29K58 showed up at what I thought was an irresistible price. So here it is. It runs very smoothly and came with a stack of leather point needles.

-

Hello I'm looking for a Supplier of needles for use in a Claes 30 Long Arm Patcher. Needle system: 88DU x 1 need them in just about all sizes but the smaller sizes are the ones I use the most of. Silverd

-

For various complicated reasons we are ceasing to do boot work and so we will be selling our Singer 29K60 machine. This is a long arm treadle model with the "splittable" arm ( there are similar machine out there with a one-piece arm which are virtually impossible to service). It has been drilled to accept a motor at some stage but we have used it as a treadle machine for the last 12 years or so. We are open to reasonable offers or would swap for a Singer 46K49 / Allbrook & Hashfield / Techsew 402 or similar. Posting here before posting anywhere else. This is a very nice, working machine. The table hardware is included but will need a new top making as it is for a short arm machine. By all means contact us for further information.

-

I noticed that the patcher sewing machines got a special movement of the needle bar compared to most other sewing machines. This is a video of the Chinese patcher sewing in some transparent fabric. Make note of the screw that fasten the needle in top of the picture: https://youtu.be/LOliY3NHg_A The needle height is controlled by a cam in the flywheel of the machine, and the hook position is controlled by another cam in the flywheel. The needle penetrates the fabric and goes to minimum height and a bit up again to form the loop of the upper thread for the hook to catch. Then the needle is hold down at same position a long time, while the hook moves forward and pulls down the thread. Then after this hook movement have finished the needle is lifted up. For normal sewing machines, the needle position is controlled by an eccentric on the main shaft and a connecting rod to the needle bar. Then the needle eye is lifted through the fabric and further up, while the hook pulls down the upper thread. This way causes a peak in thread tension near the hook, because the friction on the needle thread is high when the needle eye passes the fabric. This video explains this problem from 0:50 to 2:20 in the video: https://youtu.be/80WASgbKIX4 It is not only the Chinese Patcher, that moves the needle this way. The Singer 29, Adler 30-1 and some older sewing machines like the Singer 28 got a similar movement of the needle. I am sure, that in this way it is easier for the hook to pull down the thread, because the friction to the thread in the grove of the needle is limited. And therefore I guess that it may be possible to sew with smaller needles than normal with these patchers. Goto 10:50 in this video to see a similar movement for a Singer 29-4: https://youtu.be/aQLre-l5RkU Perhaps more leather sewing machines are made with this special needle bar movement, but I have not noticed that. Have you? I guess that you got some other disadvantages with this kind of cam controlled needle movement, and therefore most other machines are not made this way. I think one problem can be vibration at higher sewing speeds.

-

Listing for a 96 year old retired leatherworker and saddlemaker in Northern California. The ferdco has a ton of accessories I’ve included one page of the original invoice. The sewing machines are low hour and well maintained as for prices let me know about prices I don’t want my friend to get ripped off or taken advantage of, or maybe his prices are too high, any advice is appreciated. I'm sure any of these machines would come with any of their accessories like rivets, thread, needles, and anything else he has for them, He's been selling everything in his shop. Pics https://imgur.com/gallery/ZIZqXOz Ferdco $3500 Adler $2500 Stimpson riveter $850

-

Hi, I am new to the forum and have been reading around. Lots of great info here! I have recently inherited a Singer Patcher 29k71 that used to belong to my grand father who used to be a cobbler. He had lots of those, unfortunately, he ended up selling most of the old machines but fortunate for me, this one survived and was passed down to me. I was able to get it completely restored and repaired but i still cant get it to sew properly. I know the problem but i dont know how i can fix it. Problem is that it is timed properly but it constantly gets jammed because the thread ends up under the shuttle carrier. as such, i ordered a replacement shuttle carrier (not an original part) and installed it but i still have the same problem. I was able to get it to sew a few times but it ends up jamming in the end. What i noticed is that the bearing between the shuttle carrier and the driving pinion seems to stick up a little too much. As such the shuttle carrier is too high? Other thing i was thinking is that the hole on the shuttle carrier where you put the set screw is too low and when fastened on the driving pinion and there is too much play. Or the driving pinion is worn down and there is too much play. Either way, before i buy anything else, i could really use some help. Thanks! Andre

-

I' considering the purchaseof a claes or singer 29k type Patcher to help me sew handbags. Have a singer 201k M2 and a techsew 5100 already. One place I read suggested that Patchers can't or don't sew straight very well and leave presser foot marks. Can anyone comment re this? Don

-

Wanted to buy: Adler 30-5 or 30-7 long arm patching machine.....with or without treadle stand. Doesn't have to be pretty, but does need to function correctly. Thanks

-

A well tuned and maintained inexpensive Chinese patcher is my best friend. I own and use an Adler 67gk373, a Tippmann Boss, the chinese patcher from Bantam Saddle and Tack, a Stewart awl, and Mckay jerk needles as well as two-needle saddle stitch stuff. I recently found that I can use universal home machine needles as well as 15x2s. You dont have to use hard to find needles. No experimenting required. Last job was done with 69 poly and schmetz 110/18 needles puchased at walmart. Also DP 5s and PFX134LR.

-

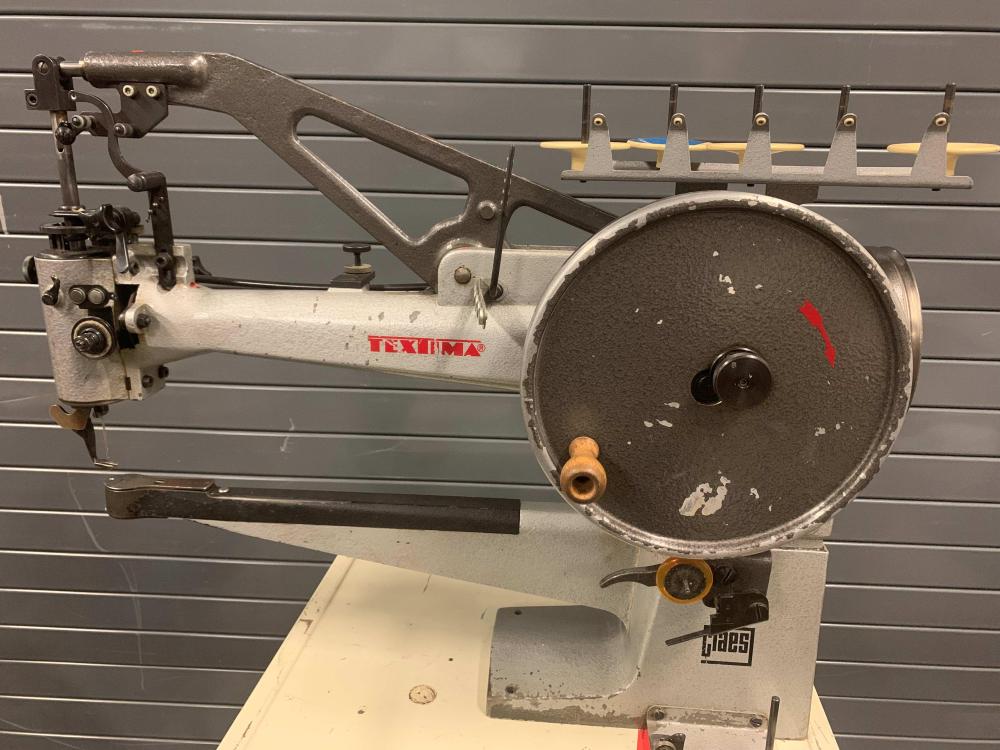

I closed up my orthotic business this year. One of my favorite and most reliable machines is for sale. It is an Adler 30-7. Please contact me if you have any questions. I feel the price is a great deal when I have checked others that are for sale. Just want to get out what I bought it for. My email is Mibracedude@gmail.com Price is $1,500.00

(Medium).thumb.jpg.eb1ed16ceb26bf69eda8f13291010240.jpg)

(Medium).thumb.jpg.ad5a6057db1354c2c2343af81e59c974.jpg)

(Medium).thumb.jpg.ea3e9d9b88b018ea30cfa59de492e436.jpg)

(Medium).thumb.jpg.a9dfc7ea201ef7b1f4e0b10c4b4d0246.jpg)