Search the Community

Showing results for tags 'presser foot'.

-

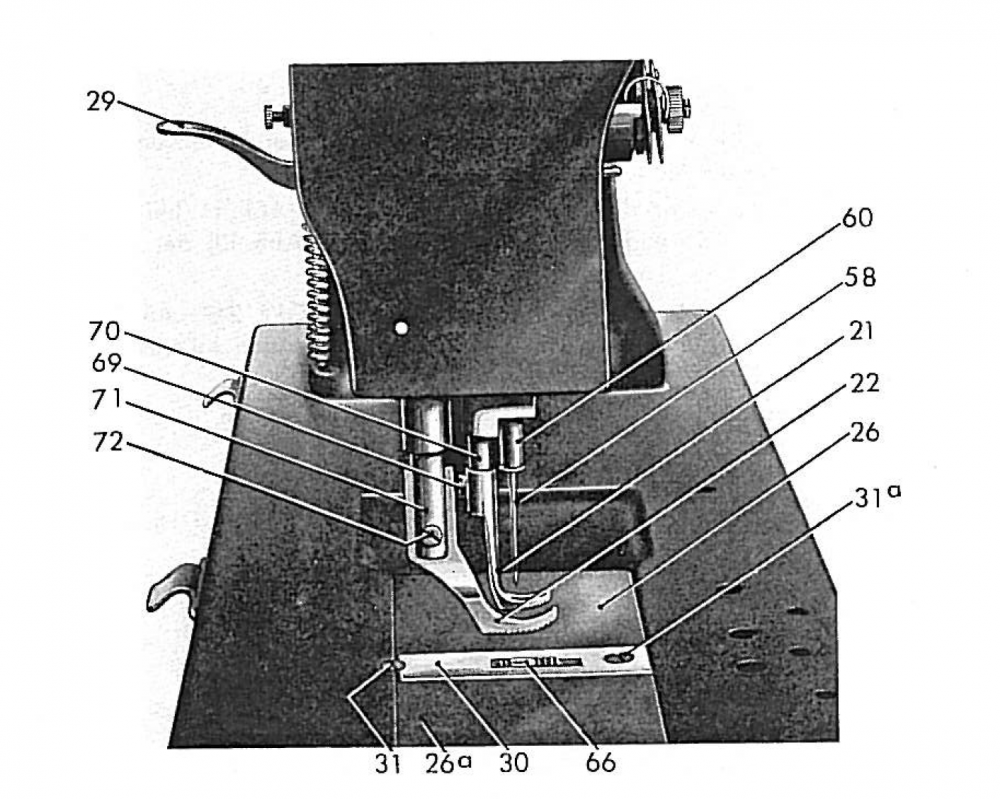

I’ve recently purchased a seiko sk8, basically a singer 132 k6. two questions.. I have a failed renovation project- a singer 45 -and I’ve found that the massive flywheel from that will fit the sk8. Is this a good modification- I’m hoping to use it for slow work and for thick shoe outsole stitching? Also on that note There’s only seems to be one presser foot type I can get.. a wide two-prong outer foot and narrow inner. I’m thinking for the outsole stitching I’ll need to grind off the right hand toe of the outer foot to get the needle close to the shoe edge.. so it will end up a one toe walker (or jumper).. Any thoughts on this? Image of the machine below part stripped for a spruce up, and the size of the 45k flywheel next to the original.. it’s a beefy change!

- 6 replies

-

- presser foot

- singer 132k6

-

(and 1 more)

Tagged with:

-

Oh my god! I have been around this machine for days, i must admit that i am kind of a newbie in this world, but i really needed and industrial machina that could sew leather to finish some college projects. So i bought this PFAFF machine from this guy where i often buy my leathers from and it came with a roller foot already attached and now i would really like to change it to a normal standard walking foot. And let me tell you... i even starting to feel like a clown because i have no idead on how to change, because it has this "spring" (i don't know the right word in english, sorry) that doesn't let me remove the last part of the foot. Please help me See the video for further detail: https://drive.google.com/file/d/1pjlj8 ... p=sharing I have already unscrewed all the screws that were to unscrew, pls help a guy out, kinda going into despair from my research i think i will have to change the whole presser foot bar and add one that can take standard foots no? anyone knows where i can buy presser foot bars online? i think what i have in my machine is something like this: https://drive.google.com/file/d/1__V6lFDxrVQfmniOAsoQUeRbek7avBdi/view?usp=sharing

-

At the attached picture, you see two presser feet for Singer vintage sewing machines with normal feed dogs. I made a modification to the right foot by cutting a notch into the foot. Have you previously noticed a similar presser foot? Do you anticipate problems by using such presser foot? I tried to sew tarpaulin near the limit for such a machine with a tex 135 thread. With the modified foot, I was able to reduce the thread tension to 61 % compared to the left foot in picture. Furthermore the required pressure on the pressure foot could be reduced to 52 %. In this way it became easier for the machine to handle the same job.

-

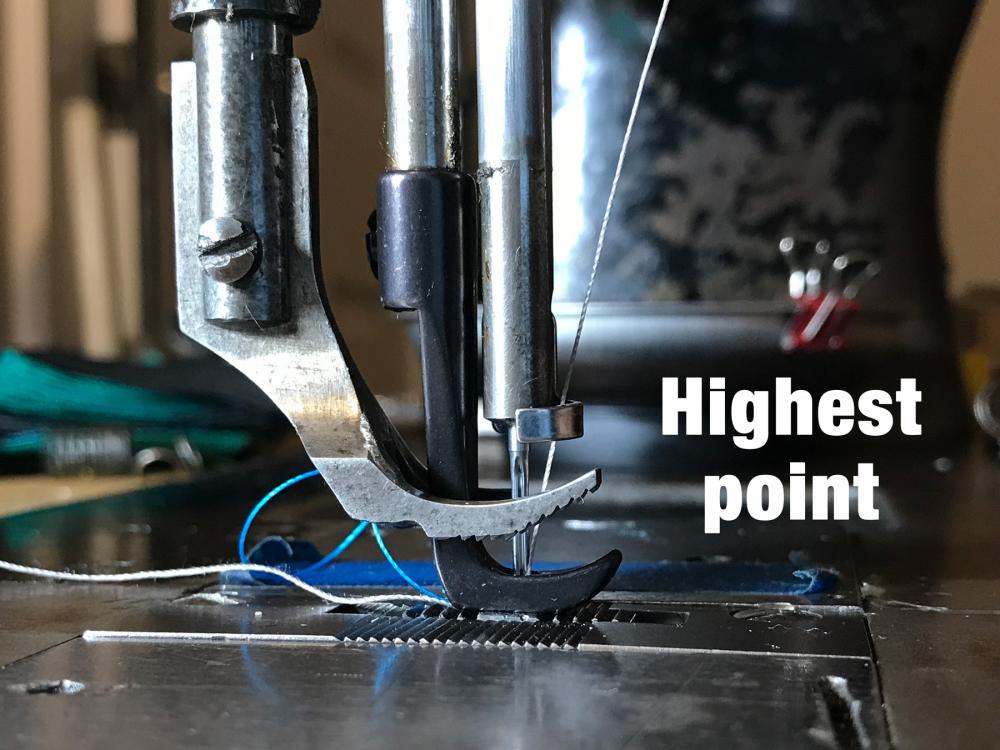

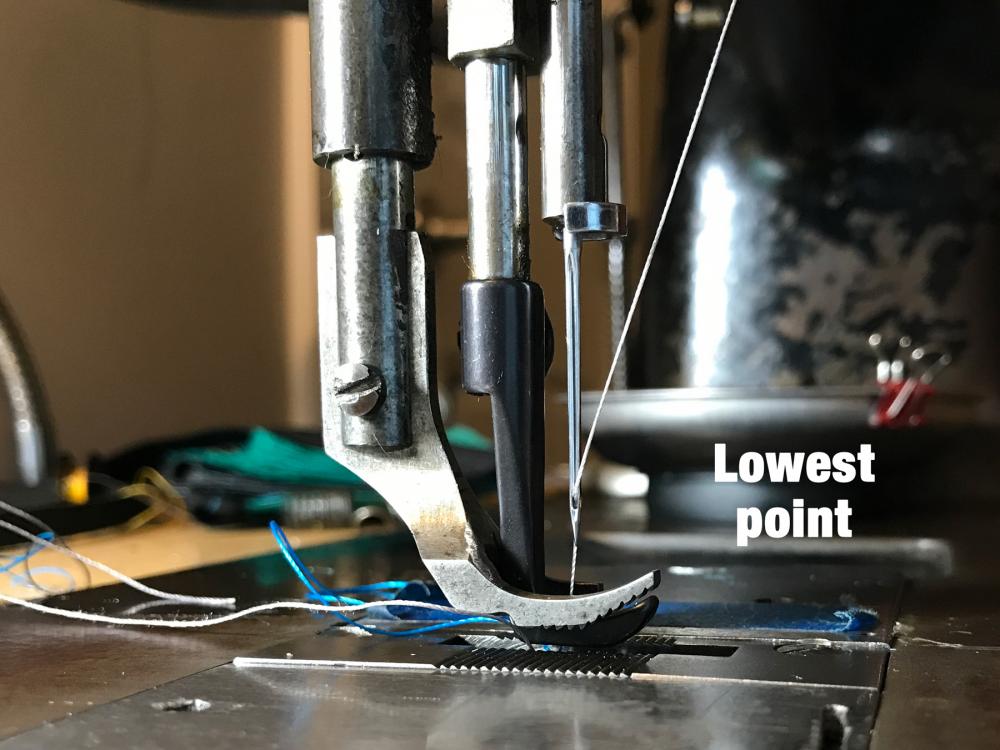

Hi all! I'm brand new to machine leather sewing so please excuse any stupid questions I bought a Seiko STW-8B - which I have since found out is often sold as a Consew 266R. It was sewing OK but had some issues with reverse stitch length which I think I solved by replacing an after market bolt which was fouling on the main shaft. I now have forward and reverse hitting the same holes - which took hours but was worth it I think. I have also fitted a servo motor as clutch control is apparently wAY beyond my skill level :D I still have a few issues which I would really appreciate some advice on. I'm going to list them all in one topic but happy to split if moderators prefer: Presser foot height and needle bar interference From watching @Uwe's brilliant video series I can see that it is possible to sew through 3 layers of 8/9oz veg tan - I would love to try this but I cannot get the presser foot adjusted high enough to even fit the material under. I have tried all the adjustments I could find on this site and elsewhere but it seems to be maxed out at around 9-10 mm on the knee lift even though the manual suggests it should be 0.5 inches - i.e around 13mm. Even when I do get 10mm of leather under the presser foot, when I try to cycle the needle, the needle bar fouls on the vibrating foot - I'm only using hand power to test this but it seems there would be interference and damage if I tried to run it under power. I have the standard 135/17 needle - do I need a longer needle and then adjust the needle bar higher and reset the timing? The vibrating presser foot seems to be off centre in relation to the needle. The needle sits dead centre in the feed dog hole but if I line the vibrating foot up straight in the middle of the lifting foot, then the needle is very, very close to the left edge of the vibrating presser foot hole. I can remedy this by rotating the vibrating foot slightly to one side so it does not run true from front to back - but surely that isn't correct? The timing seems to be correct (seems!!) but in reverse it is skipping stitches every time - and I'm pretty sure the top thread is just being missed by the hook. Is there anything obvious i could have messed up or do I just need to check the timing again? Thanks so much for your help - I only discovered this website a few days ago and I am hooked - so many helpful folk out there! Mb

- 17 replies

-

- presser foot

- reverse

-

(and 2 more)

Tagged with:

-

Hello all, I bought a singer 119-2 cylinder bed sewing machine and it is working fine after some tlc and a new servo motor. I would like to replace the walking feet with ones that would allow me to see the needle. The one i have now the needle goes through the front foot and makes it hard to see where im sewing especially around corners. Is there a replacement foot that will fit this machine? Having a hard time finding info on this. So far all i have seen is a foot that comes on the 78-3 but it has some teeth on the bottom and i was trying to stay away from that if i can since im sewing leather. Also i have my tension really high. I works fine but just seems really tight. I had to tighten it that much to get the seam right just doesn't seem right. Im using 138 size thread. Should i replace the tension assembly? Any info would help thank you.

- 7 replies

-

- sewing machine

- tension

-

(and 1 more)

Tagged with:

-

Hello all Does any one know where I can find a good zipper presser foot for a Durkopp 239? Seems hard to find for these old machines on the web. All the feet I find is for newer Durkopp/Adler machines. Are there any other durkopp numbers or brands (like Juki) fitting this machine? Thanks

- 2 replies

-

- presser foot

- zipper

-

(and 1 more)

Tagged with:

-

Hello everyone, I found this forum a while ago but this will be my first post. I only had my Cobra class 26 for about 2 weeks but I love how this machine functions, I'm learning every day more things about it. My problem (well other then learning how to stitch better with it) is that the presser foot marks the material, on chrome tan is not that noticeable but on some of the vegetable tan sometimes it marks it pretty bad, is there something I can do to not marker it that bad, or maybe a new foot I can buy for this purpose? Thanks everyone. P.S. I tried to search for this on the forum but I couldn't really find anything.

-

I have a Techsew 5100 se and I need to adjust the height of the presser foot but I have no clue on how to do this, watched the dvd read the manual and neither mention how this is done. Any help is appreciated. I'm trying to lower it all the way down.

- 9 replies

-

- techsew

- presser foot

-

(and 1 more)

Tagged with:

-

Hello, I am trying to max out the height of my presser foot while sewing multiple layers of leather on the Consew 206rb-5. I am wondering if it is safe to just follow the manual on that one under 'Adjusting the Lift of the Alternating Presser Feet' ? Will this mess with needle timing or anything? Any other tricks to max out the height? Thanks!

-

Hi! What kind of inner presser foot for a walking machine lets you sew very close to the edge? Do I have to make one from a regular foot attachment? Thanks!

-

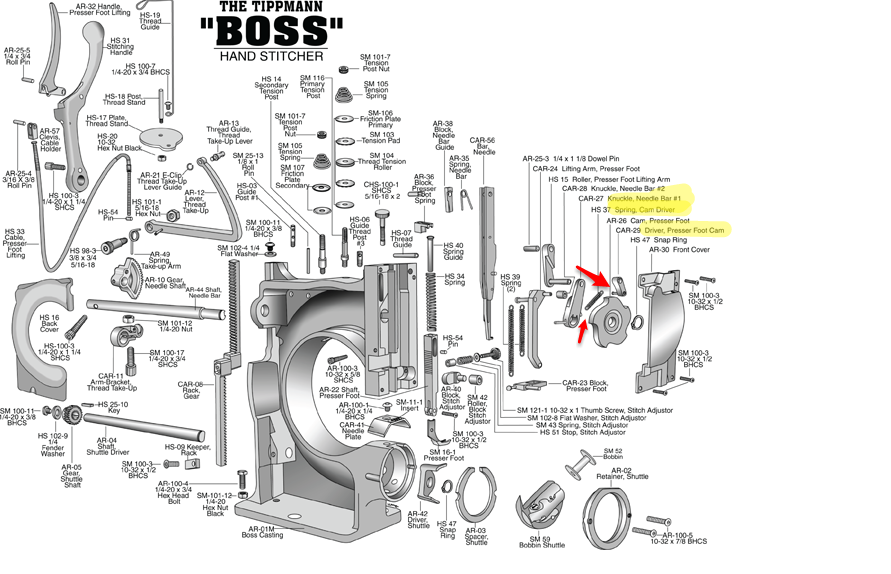

Hello, I just bought a used Boss and had to get a replacement cam driver spring. According to the exploding Boss diagram on Tippmann's site (tried to paste below) but is also here: http://tippmannindustrial.com/the-boss-parts-finder/ .One end of the spring attaches to a small pin on the presser hook cam driver and the other end to a small hook on the knuckle needle bar behind the cam. Tippmann says it can be attached without removing the cam itself, but I'm unclear how the spring gets attached to the small pin on the cam driver--it's got a slit going lengthwise down the pin and the spring has a loop on each end. Has anyone here ever had to re-attach the spring? Ack! Basically means my mechanical skills are rather bleh Lori

-

I'm relatively new to the world of sewing and I've begun to get my Singer 111W113 back in working order after having it in storage for the past two years. When I bought the machine back in 2014 everything was aligned and the outer presser foot operated properly. While putting everything back together I'm realizing that the outer foot has far too much clearance, especially when sewing a few layers of material. I'm currently working with a lot of Cordura and heavy canvas for making bags. 6+ layers of Cordura are thick enough to make contact with the outer foot and provide pressure. Less material just slides around freely. I've made attempts to adjust the height of this bar but it seems to be in it's lowest possible position. Is there more to adjusting the outer foot pressure / clearance than just the screw on the top rear of the machine? Thanks in advance!

-

Hello, I just purchased a new cobra 4 sewing machine and have been noticing that when sewing slowly the outer presser foot comes up in a very jumpy manner. Kind of like a stutter. It kind of concerns me that the rod holding the outer foot might be off in some way - and I don't want to continue any damage to this new machine if something isn't set right. Anyone have this issue with that outer presser foot when it is pulling up? Still does it even when I pulled the foot off. The rod is pushing up on the large tension spring on the inside of the case, so my thoughts are that this could just be some physics about the slow speed against a high pressure spring. Any thoughts? Just want to make sure either way before moving forward!

- 21 replies

-

- presser foot

- cobra

-

(and 1 more)

Tagged with:

-

I bought a Cobra 4 a couple of months ago. It's brand new and needed a little adjustment when it arrived to get going. Things were going great until three weeks ago. When I returned from a convention in Texas, problems ensued forcing me to hand stitch the projects I have waiting. I contacted Steve, but we don't have a resolution yet. Here are my issues I can use help with. Presser Foot: It is coming up as the needle is traveling upwards at the end of stitches. Needle: Bending on shuttle and breaking. I've had to force the needle up higher to see the end in the window. I've been using channel locks and a lot of elbow grease to get it done. This cannot be the best way but is necessary. Bobbin: I can pick up the bobbin thread with my needle when initially change out the bobbin, but after that, nothing. I find myself just poking a lot of holes in my leather rather than stitching. I'd be grateful for any assistance. I have projects customers are waiting on, but I'm having to hand stitch everything from chinks to holsters, saddle skirts and harness. Thanks, Philip Crabtree www.CrabtreeSaddleWorks.com

-

Left Toe Presser Foot for Cobra Class 3 or 4. I would like to trade for a right toe presser foot or sell. Brand new never used.

-

Hi all, Hope someone can help... I'm in the process of cleaning and refurbishing a Singer 211G156 and I can't get the presser foot to operate properly. As soon as I bring the lever near the top of its travel, it jams and I have to use a drift and tap it lightly from the top for the presser foot to drop back down. I have cleaned everything I can and oiled it thoroughly and it still jams. I even used a mechanic's stethoscope to listen at different moving points and the loudest noise comes from the top of the presser foot rod in its tube. Needle moves freely, no problem there. When I opened the front cover I noticed right away that someone had pried the legs of the presser bar position guide (a tuning fork looking thing). I should have taken a picture of the distorted guide. Once I figured out how to remove the position guide, I straightened it in my vise and filed off the damage the bending had done to the part. When I reinstalled the guide, it didn't make the movement any worse which tells me it wasn't the problem in the first place. One thing that still puzzles me though is whether it's a hard job to dismantle/remove the presser bar, that way I could lightly ream the tube and reassemble the unit. I'm sure THAT would solve the problem but I'm at a loss on how to dismantle it. Any help would be greatly appreciated. Thanks in advance. Skylark53

-

I have some Singer 45K parts for sale as I need some coins for other toys All parts are used but full functional. Can post more pictures if needed. I ship worldwide and I take Paypal. Worldwide shipping is $8 for registered Airmail for single items. I will combine shipping to safe some shipping costs. Discount on multiple items is possible. 1.) piping foot - you need the foot adapter if you want to use it. $25 2.), 3.), 4,), 5.) presser for walking foot type Singer 45K or Adler Class 4 +5 - each $25 Great for making your customs presser for special purposes or so.

- 28 replies

-

- bobbin winder

- spare parts

-

(and 1 more)

Tagged with:

-

Howdy, I'm wracking my brain trying to figure out why my Pfaff 335 is marking my leather, especially at the start of a stitch line where I backtack. I've attempted to lighten the pressure of the presser-feet by backing off the knurled nob at the top of the machine, to the point it is barely hanging on to the machine, but it doesn't seem to have much of an impact. The inner presser foot seems to be fine, but the out foot is an issue. I've even placed my finger under the presser foot (machine off and needle out of course) to see if I can feel any difference in the pressure bing applied... I'm not sure what it should feel like, but its heavy. Seems like the the top pressure is not being affected by loosening the knob on top. That said, I haven't a clue what I'm doing. I've included a few picture to show how loose the top knob is, the position of the presser feet (they seem a bit canted to the left) and the marks being left on the leather. BTW... I'm stitching 3-4oz harness leather from Wicket & Craig. Any ideas whats going on here?

- 21 replies

-

Sometimes when I'm sewing through several layers of waxed canvas, a few stitches in from the starting edge, the trailing work edge will hang up at the rear of the needle plate's nfeed dog slot. All forward movement of the material stops and stitches pile up. If I can get the material to move just a little bit more, the trailing edge gets past the rear of the slot and doesn't catch there any more. Is this caused by too much presser foot pressure? Picture attached.

- 6 replies

-

- waxed canvas

- presser foot

-

(and 3 more)

Tagged with:

-

I recently bought a Tippmann Boss with a boat load of accessories. It had a presser foot in it that I can't identify. Can anyone tell me what it is and how it is used?

- 4 replies

-

- boss

- presser foot

-

(and 1 more)

Tagged with:

-

I was wondering if you guys can advise me on how I can lighten the presser on the presser foot so it will not leave walking foot marks on the face of my leather. Thanks guys, Chris

-

I was wondering if you guys can advise me on how I can lighten the presser on the presser foot so it will not leave walking foot marks on the face of my leather. Thanks guys, Chris Sorry for the double post.

-

I have a Ferdco Pro 440, bought this about 8 years ago. Yes, this was before I learned more about leather sewing machines. One of my challenges is skipped stitches. I was reading another topic and saw that if you adjusted the needle penetration into the leather that helped. I will try that. My main irritation with this machine is the fact that even when I take as much pressure off the foot as possible the foot still leaves marks on the top of the leather. I'm wondering if the spring that pushes down on the presser foot is too strong or long. I, of course, don't have any repair manual and the people who sold these machines have gone out of business and are no help finding any kind of resource for adjustments. I'm hoping someone out there can help. Thanks a lot Pat

.thumb.jpg.a9c359ca6345fe7ca930db50ea8f861d.jpg)