All Activity

- Past hour

-

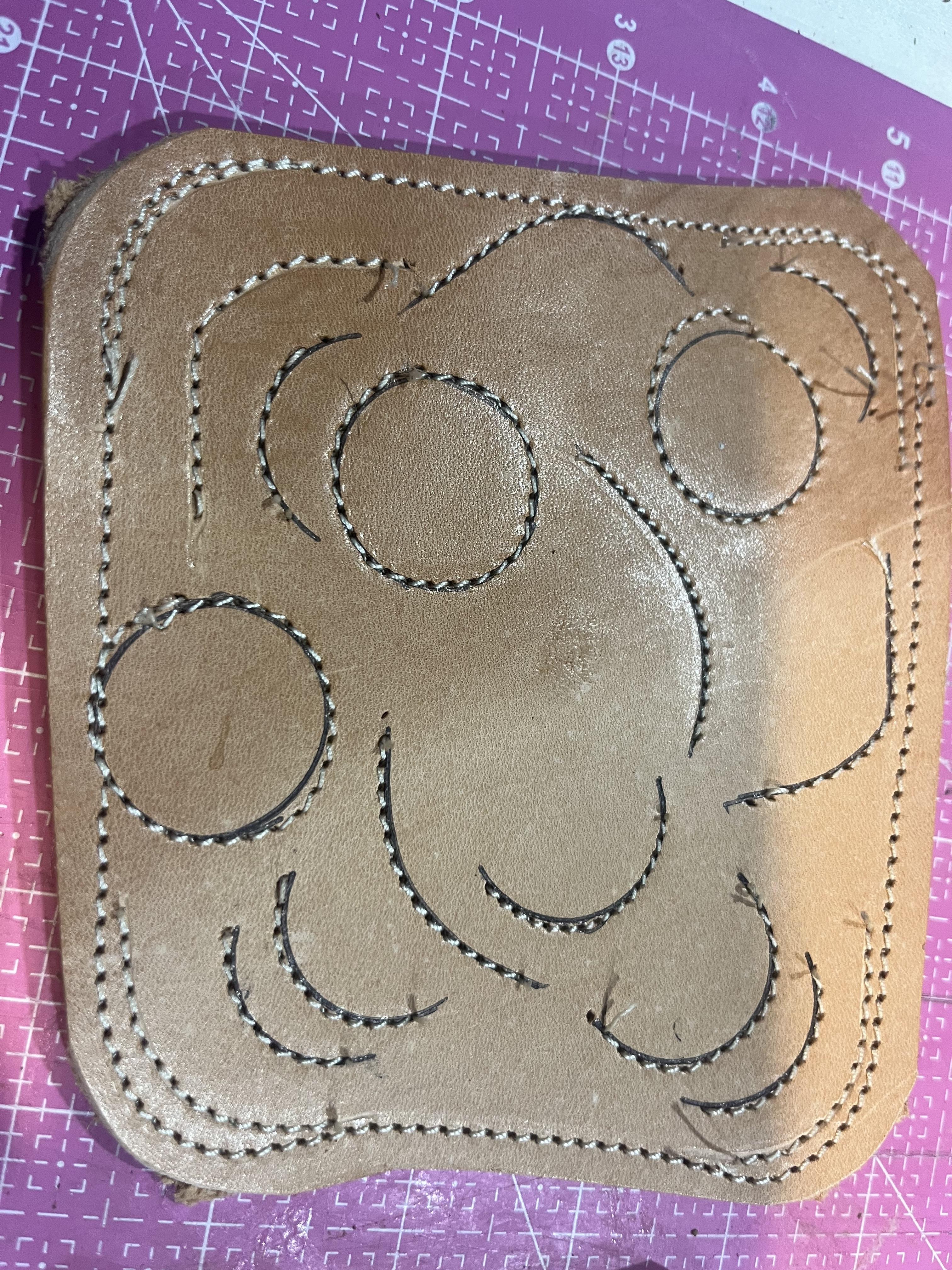

So I got a sewing machine a few weeks ago and have been messing around with just learning the basics of my machine and in that time, Ive realized that i suck a sewing around corners. So I’ve been coming up with practice exercises. Basically following the lines with my machine. I traced some quarters to practice circles. Obviously I’m terrible at sewing and have a ton of practice ahead of me but does anyone have any tricks or exercises that they use to practice sewing?

-

Thanks Chuck! These leather shows are a lot of work but a real blast. Aaron does the walk-around video tours at each trade show and he's done a real service to people that wonder what a trade show vender area is all about. That is just a portion of these shows, the classes are outstanding and top notch instructors. Socializing with other leather workers, meeting the superstars and worker bees, these people are my tribe.

- Today

-

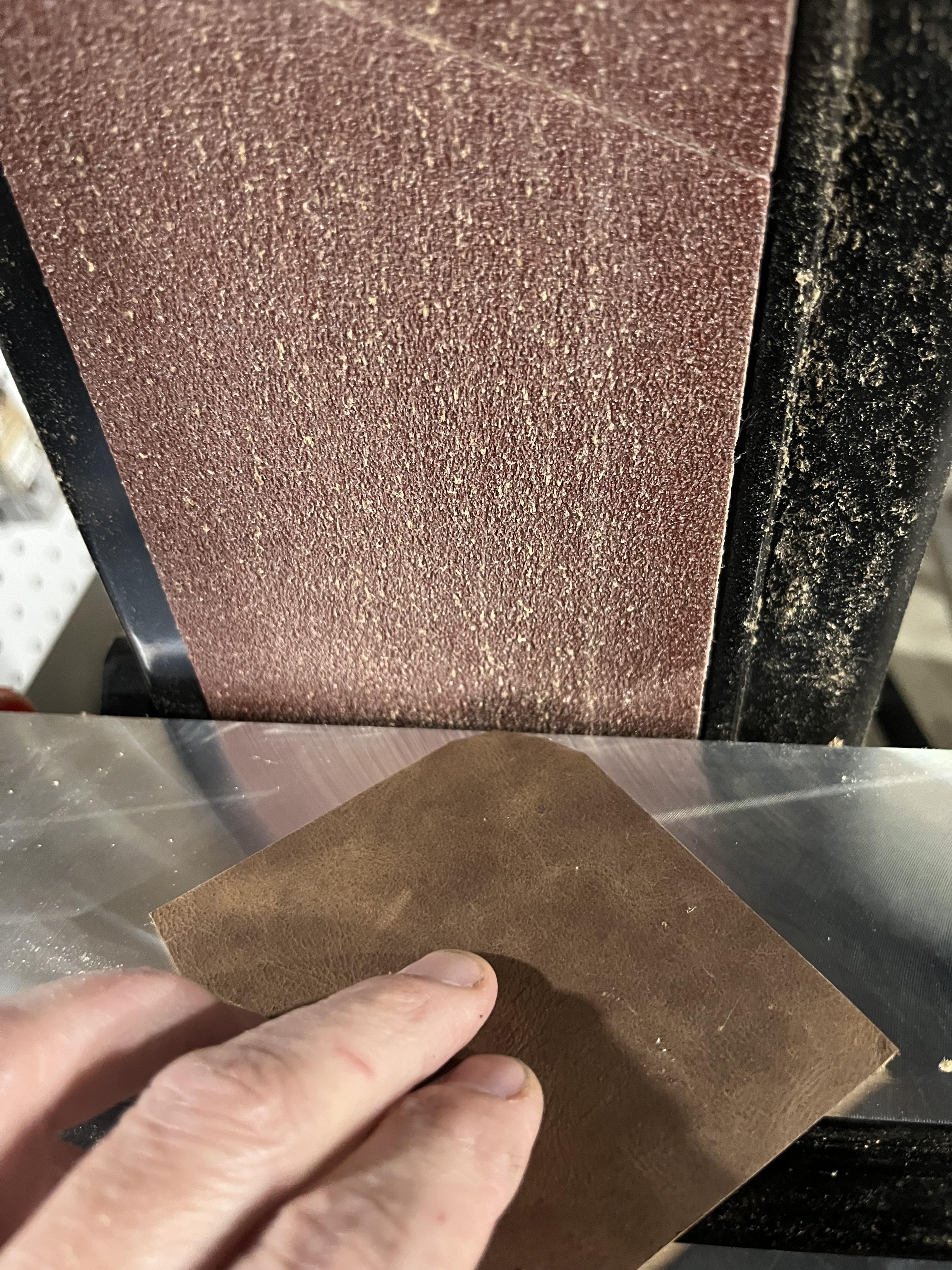

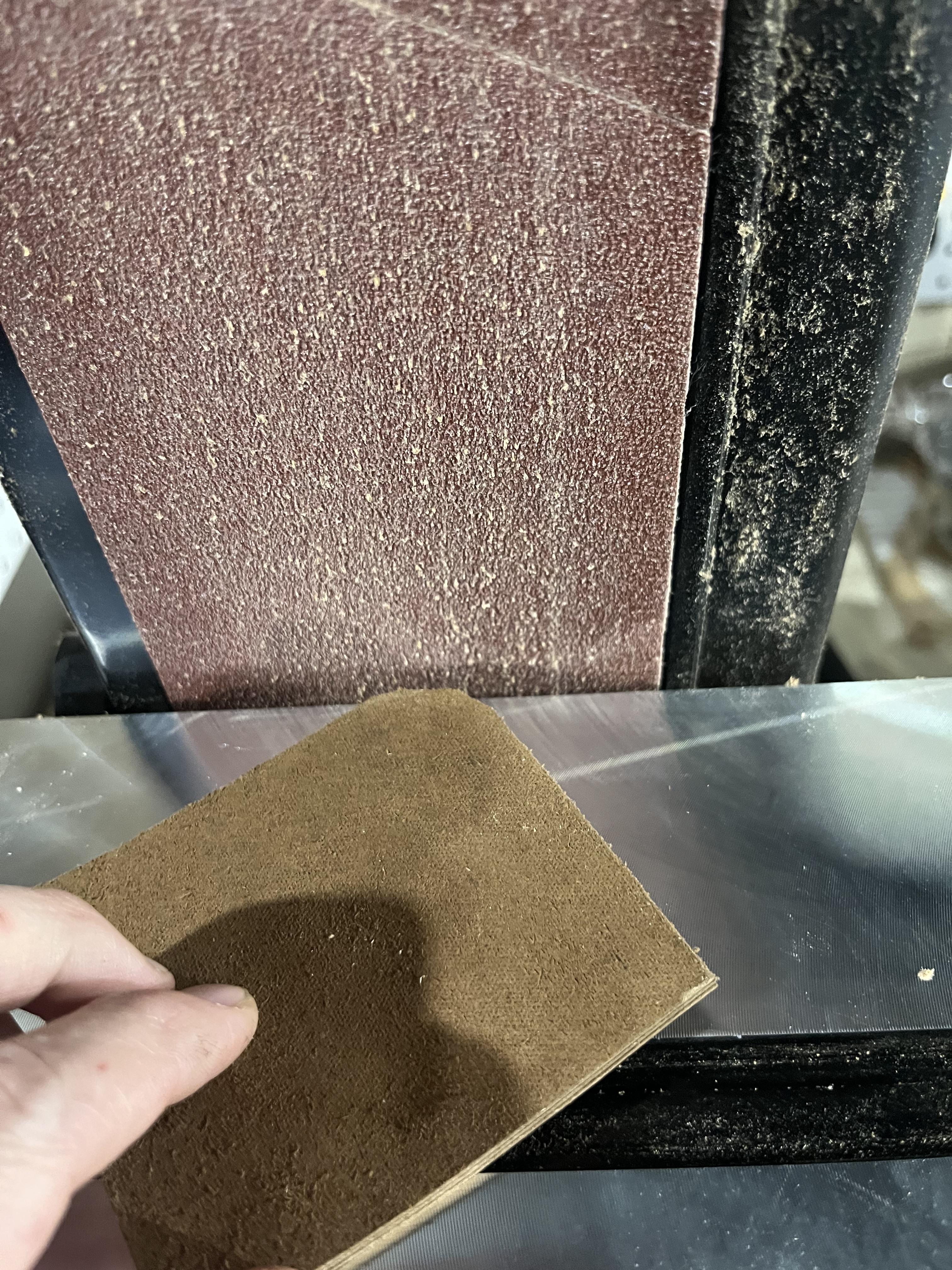

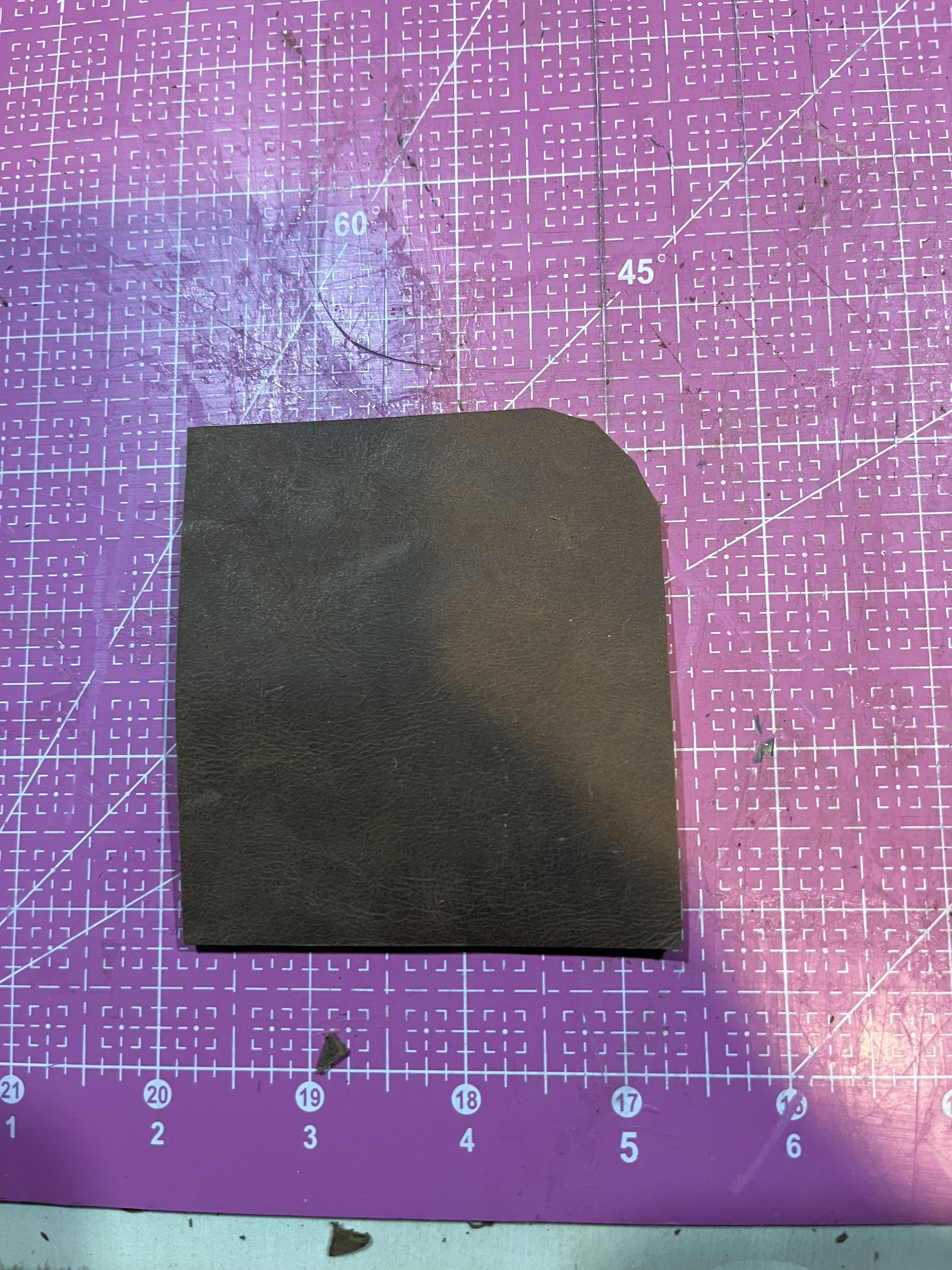

So this is what I was able to do with 60 grit belt. I sanded the top and flesh side slowly flat on the table. The I sanded the flesh side against the belt and finished up by sanding the edge. I’m gonna grab lower grit belts tomorrow.

- Yesterday

-

CLEAN !!!!!! What stamp is that if you don't mind me asking ?

-

what did you miss at the pendelton leather show video

rleather replied to chuck123wapati's topic in Leatherwork Conversation

Thanks for sharing Chuck! Good stuff! -

A finer grit and go slow, not too much pressure as it's easy to burn the leather. I think chrometan is going to be problematic as it's generally a softer leather. And yeah, it can make a lot of dust!

-

A friend of mine in the States needed an ammo pouch for his 16ga / 7x57 combination gun so I made one for him. I also bought a new stamp to try out.... Roger

-

I only sand to even up the edge, to take out bumps made by my bad cutting, or similar. I sand by hand. Depending on how bad the edge is I'll start with an 80 or 120 grit, working thru 240, 320, 400 to 600

-

I usually sand by hand unless it is a multi layer knife sheath, holster or scabbard. If the edge is pretty square I use 200 then 600, if it needs a little squaring then I start with 150, and that usually gets me a nice smooth slick edge. I use water and saddle soap for the slicking part. Todd

-

A lot of people sand edges like I would a table top, progressively finer down to pretty fine grit. I use my sander to roughly clean up edges with 80 to 120, depending on what's on the machine. Never hold it long enough to build heat. For the most part I'm evening up layers or cheating an edge to parallel with the stitching. I might hit an edge with 150 by hand before slicking it down. Bear in mind, I'm not interested in super slick, polished edges. But, yeah, that sander can do a lot of damage in a hurry.

-

I really admire those that hand sew and tool leather but for me I don't have the temperament or the artistic ability. So for me it is all mechanically aided, sewing machines, presses, skiver, embosser, 3D printer, etc. kgg

-

I do agree with @Dwight but the grit of the sand paper selected has a lot to do with the speed of the machine. Too course a grit say 60 at slow speeds will tear chunks out while too fine a grid at high speed will burn. I use 120 grit on my machine which is a modified variable speed bench mounted buffer with a 4 3/4" long X 3"diameter sanding disk at 3400 rpm. kgg

-

I haven’t seen a bag like that before. Very cool! Maybe Tandy’s mini saddle template could be incorporated? (I have no clue about the size of the finished product) — AZR

-

Springfield Leather Co has a free template for a mini-saddlebag-type purse. I’ve recently made a couple bags from the template, and personally, I think it’s a cool design. It is reminiscent of motorcycle saddlebags versus horseback, but check it out, maybe it’s up your alley… Hope there’s no copyright issues here, but it is free… — AZR MiniSaddleBag.pdf

-

BBC caught with its knickers down . . . .

Darren8306 replied to fredk's topic in All About Us and Off Topic

There can be no accountability. At least I am not forced to pay for their production of 'news content'. -

I took another approach to punching oblong holes in leather belts. I 3D printed two simple jigs, one for the belt buckle holes and one for the other end. kgg

-

Thank you Dwight. My belt is an 80 grit b/c that’s what it came with. I’m gonna do all your suggestions and we shall see.

-

You need to do 3 things: 1: get 120 or 150 grit sandpaper . . . and you may even want to to up to 180 or 200. It looks like you have 80 or 60 grit on there now . . . and it is way too coarse. You also might want to hook up a vacuum to the sander . . . I did with mine . . . it grabs the dust and makes a better experience. 2: move your machine so there is almost zero distance between the sandpaper and the shelf on which the leather will sit. Mine would not move so I made a topper for the table . . . out of 3/16 basswood plywood and contact cemented it to the table. I purposely changed the sanding belt . . . and then placed the plywood shelf up so it was just barely touching the sandpaper. When I started it up . . . it sanded the plywood slightly . . . but left a VERY THIN space between the shelf and the sandpaper . . . THAT is the desired effect. 3: make sure your table is exactly 90 degrees angled from the sandpaper. I sometimes have a problem with seeing my project . . . so I outline where I want the sanding to go with a black ball point pen . . . and I sand it until the ink line just disappears . . . works perfectly. The technique is to slide the project back and forth . . . barely touching for chrome tanned . . . you can apply a bit more pressure with veg tan . . . especially if it is layered thicker . . . like a knife sheath or holster. When you have your desired edge . . . comes the final tricky part you need to do. Turn your project over and VERY LIGHTLY touch the sandpaper. It will take off a little "edge" that the earlier sanding produced. Try it . . . you'll like it. May God bless, Dwight

-

Actually if you do it that way . . . it is about identical to the one Weaver Leather sells for some exorbitant fee . . . I don't want anything in my shop to be intentionally built or made by me that could be interpreted as patent stealing. That's why my design did not use the stiff wire pointer . . . theirs does . . . But going back to your clear plastic . . . do you actually have the plastic? And do you have the drawings? Reason I ask . . . I have a laser engraver that I've never used on plastic / plexiglass. AND . . . what little I have . . . it is really thin . . . wouldn't work for the thicker belts I make. I'd be interested in doing a "shared experience" project if you could supply the drawings and plastic. I'd put it on my machine and see how well . . . or even IF . . . it would work. We would both learn something from the process. So far . . . I've cut 3/16 basswood plywood very successfully . . . but that is about all I've cut. It engraves beautifully. May God bless, Dwight

-

I made a bigger jig like this years ago, out of thick plastruct plastic sheets, and used chicago screws as the pivot points. To make it a little more versatile, I sized the centering holes the same size as the other holes, and with a couple more screws that allowed me to add a third arm in the center which can be exchanged for different needs, exactly the same length as the ones at the edge. Need extra small belt holes? Make a center arm with small holes that fit that small punch. Need an oblong for the buckle tongue? Make a center arm, use that oblong to punch the plastic the right size and orientation and your oblong is centered and as straight as you were able to make get the plastic. You can also make a couple of holes in the edge arms and add a stiff wire pointer to set up hole spacing to help you move the jig the right distance for even holes. I took the idea so far as to put the design into cad software with a measurement scale on the arms to assist with spacing, and some accessories with the intent of having it laser cut in some nice clear plastic! Unfortunately, before the laser cut folks could get to my project, they went out of business. So, for now - my old jig still works even if it doesn't have all the niceties. - Bill

-

BBC caught with its knickers down . . . .

chuck123wapati replied to fredk's topic in All About Us and Off Topic

And if you think the BBC are the only ones doing this shit your dumb enough to believe them. -

Need more info, how was this jig made, I need a bit more depth Need more info, how was this jig made, I need a bit more depth

-

This is a question that needs addressing. I feel that many of the videos that are out there are misleading inasmuch as hard thick leather is used or the amount of work involved in burnishing is understated. I too have found that the initial sanding raises so much more fibres than expected and I realise that a lot more work is needed to be done and wished I'd left it alone in the first place.