All Activity

- Past hour

-

Far too nice for groceries m'thinks, By far too nice

- Today

-

Depending on the style of edger; rub a lot of compound an a length of string. Tie one end of the string to something, hold t'other end and pull it tight. Rub the blade up & down the length of string

-

Can you post a link to the 30mm pulley you bought? I ordered one but it arrived today and it's narrower than I expected. Only a 7mm gap for the belt, and my belts are 6.5mm wide on the inside edge, 9.5mm on the outside edge. Once you get it set up I'm curious to hear how it is to move the handwheel manually. I've been wondering what is the optimal motor size and gear reduction that gives plenty of torque but is still easy enough to manipulate at the handwheel. I've got a 1-hp 3-phase gearmotor (4.5:1 gear reduction) on the way, it will be my first VFD setup and my first system that is geared down more than just putting a small motor pulley on it.

-

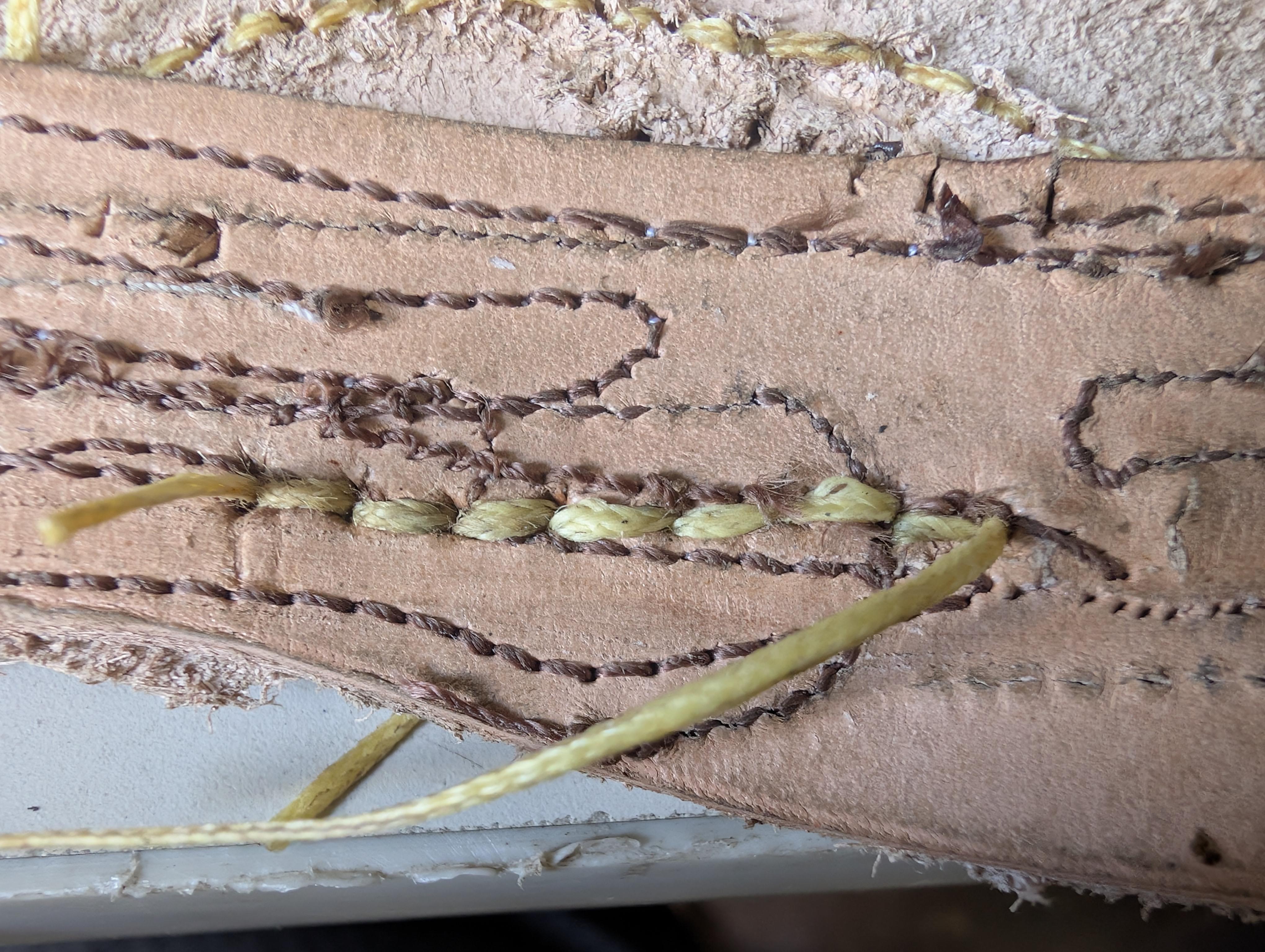

Lacing or Thonging a Mitered Box Corner

DoogMeister replied to MikeF's topic in Leatherwork Conversation

very nice work! -

I've wondered how much torque increase we get from speed reducers. Is it inverse to the speed reduction? Turns out it is. If your speed reducer provides 1:3 speed reduction, you're getting a 3:1 torque increase. (The following assumes a start up speed of 100 rpm at the motor) But, even though you can put a 30MM (basically 1.18 inch) pulley on your motor against a 3" hand wheel and end up with a final decrease of 1:2.5 (39 rpm) and corresponding torque increase, you're still better off throwing a 1:3 speed reducer in the middle. Adding the typical 2"/6" speed reducer to the above gives you a speed reduction and torque increase factor of a whopping 7.58. Most of what I've read indicates that servos want to run at or above 300 rpm for cooling. The setup imagined above with the speed reducer would be around 40 stitches per minute at a 300 rpm motor speed. (it's not only imagined, it's bolted onto my 111W153, patiently awaiting the 30MM pulley) duck.ai provided confirmation about the torque increase. Now properly credited, here's what it had to say: Understanding Torque and Speed in Pulley Systems Torque and Speed Relationship In a pulley reduction system, torque and speed have an inverse relationship. When the speed of the driven pulley decreases, the torque increases. This is due to the mechanical advantage provided by the pulley system. How It Works Larger Driven Pulley: If the driven pulley is larger than the driver pulley, it will turn more slowly. This results in increased torque at the output. Smaller Driven Pulley: Conversely, if the driven pulley is smaller, it will turn faster but produce less torque. Calculation of Torque The torque available at the driven pulley can be calculated using the following principles: Torque Multiplication: The torque at the driven pulley is multiplied by the ratio of the diameters of the pulleys. For example, if the driven pulley is twice the diameter of the driver pulley, the torque is effectively doubled, while the speed is halved. Practical Implications This principle is commonly used in various applications, such as: Automobiles: In low gear, the engine speed is high, but the wheels turn slowly, providing more torque for acceleration. Conveyor Systems: Slower speeds can help manage heavy loads without slipping. In summary, in a pulley reduction system, as speed decreases, torque increases, allowing for greater force to be applied at lower speeds. Sciencing aimsindustrial.com.au So, until someone comes up with a servo offering 7X more torque than current offerings and running at a minimum 50 to 100 rpm, torque increasing speed reducers are king.

-

Edge beveling 101

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

I have started taking my edger to my buffing wheel, which did have an immediate (positive) effect, but as I can only get the back/bottom side, how do I sharpen the cutting blade itself? -

Edge beveling 101

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

Thank you, it’s been puzzling me. I also noticed about the flesh being a little easier to work, so I guess I’m on track, but thank you for clarifying. AZR ps Your Stan Lee is amazing! -

Landis No. 16 Installing The Head Of Machine

Cumberland Highpower replied to BattleAx's topic in Show Off!!

Sometimes I wonder things like that. Sometimes thoughts like that are a bit off though. We always think in terms of ourselves, family run shops, etc. Truth is allot of these machines went into big production shops/factories. Nobody wants to dream of their personal machine being one of 20+ operated by punch clock, floor workers for 60+ years and then sold off at an auction in 1990..... My 16 has a brass tag on it that a factory installed on it generations ago. (not the factory tag) probably an inventory/property number. Of course nowadays that those machines are essentially "out to pasture" in small shops/hobby shops that would fit pretty well. -

Need to sew patches . . . help!!

chuck123wapati replied to Dwight's topic in Leather Sewing Machines

If you didn't think of this already. Call him and buy his machines if you can. -

I would suggest a long arm in a used machine Singer 29k-72 or 73 the only difference being the end of the cylinder bed are slightly different. As for new there are to many clones available so just go with who gives the best price and after support. You might also want to contact the person who just up and quit and see what equipment they have that maybe for sale. @Wizcrafts should be able to provide good sound guidance. kgg

-

Moved your post to leather sewing machines. You are looking for a patcher. @Wizcrafts has lots of experience with sewing patches and can tell you about it (and of course, lots about sewing machines).

-

I am looking to get into the patch business as the last one in this area just up and quit. I need suggestions for a patch machine . . . and a quick couple of paragraphs on how they work. Thanks, may God bless, Dwight

-

You can use other needles systems but you have to adjust the needle bar height. I´d be glad if I could find a 97 on my side of the pond. 😁

-

https://www.ebay.com/itm/157174686380 Not mine (obviously) but could be interesting for some folks in the US. Ex factory it is a straight stitch and cam controlled 3-step 8mm wide ZZ machine (subclass 135). It shares presser feet, feed dogs, needle plates and probably some other parts with its "older sisters" like 107w, 143w and the like. Found it as I´m about repairing one and looked for information cause I have one here that needs a new cam. 🤥

-

How to search for single word with three characters

friquant replied to friquant's topic in Feedback and Suggestions

The google search works 👍 -

How to search for single word with three characters

Johanna replied to friquant's topic in Feedback and Suggestions

It's like the old time infomercials in the middle of the night. "But wait! We can sell you a new magic database tool for a gazillion dollars, that may or may not work any better than what you've got! Call Ronco now and save 15%!" Follow Tom's advice to search the site by Google. -

I always get that same feeling around old tools. It makes me feel privileged, that today, many of us are able to do something for a hobby, that was once the bread and butter for a family. Genuine wear adds a certain beauty to many things. Brgds Jonas

-

Nicely done. I like the steel toed sandles too!! Love my Landis Nr.1. God bless.

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

How to search for single word with three characters

Northmount replied to friquant's topic in Feedback and Suggestions

Some databases don't index 3 or fewer letters words. Easy way to not index "the" and many other articles reducing the amount of space or keys required by non-essential words. Some DBs allow you to specify what gets dropped and what to keep. -

Removing molding marks?

larry1096 replied to larry1096's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I think very detailed boning is partly aesthetics, partly to enhance retention. I continue to work toward the level Mr. Ingles demonstrates, though I've a long way to go. Larry -

How to search for single word with three characters

Johanna replied to friquant's topic in Feedback and Suggestions

I just searched "awl" and got nothing. I wonder if there is a setting somewhere for the online search function? Friquant has me off to the races again. Thanks for the heads up. - Yesterday

-

Lacing or Thonging a Mitered Box Corner

Chipster99 replied to MikeF's topic in Leatherwork Conversation

That’s some pretty spiffy tooling work right there…very nice job!