All Activity

- Past hour

-

Lots of great pointers in here already. I'd add that Weaver Leather Supply has a line of YouTube videos by Chuck Dorsett explaining how to do various individual skills and walking you through various projects. Those are immensely helpful. Armitage Leather's videos on saddle stitching are the best I've seen. And, if you have a Tandy nearby, taking in-person classes is a great way to get hands-on guidance with a skill—you can only get so far trying to teach yourself.

-

Marvelous work! I see why you now feel you should have just bought him one, lol.

-

Is there a sewing machine for me?

friquant replied to D.jsherwood's topic in Leather Sewing Machines

Pfaff 545 is a flatbed with triple feed (aka walking foot) that I see come up on marketplace for $600 - $800. That's what I bought as my first machine. It's biggest fault for me was the stitch length only went up to 4mm. -

thanks for the reply. the 246 I recently used was a -7 model and brand spanking new. I will check with foresewing. these two are at advanced sewing in pittsburg. I use heavier fabrics, ultra 400tx, all weights of cordura, 16 oz ballistics, ultra 800tx as well as light dyneema, so have different machines for different weight fabrics. whatever cylinder arm I end up with won't be a full time binder nor used on the lighter fabrics.

-

https://tandyleather.com/blogs/leathercraft-library/1917-saddle-bag-pattern-pack?_pos=1&_psq=1917&_ss=e&_v=1.0

-

Around the disc? Meaning more than what is shown in the photo? (The photo looks correct to me)

-

My son just started in construction and asked for a tool belt. I should have just bought him one. It was a fun project and like most things for me, I immediately wanted to build another to fix my mistakes. Critiques are welcome. Randy

- Yesterday

-

Hi John, I also make backpacks and use a 246. To start, for perspective, I paid ~$2500 for my machine with table, servo w/ needle positioner, and a couple other items towards the beginning of 2025. This was with a local guy. These are not too common, Unft. I did not pay for shipping but the fella who found the machine for me in PA did replace a few parts including the hook with Genuine Juki parts. This was a newer style 246, not the older style as is the one you are currently looking at. I can confirm it can easily handle 14 needle and v46 thread. With the fabric you tend to use, you will have no problems even with just two layers but IMO two layers of ~150-210d is about the min I think it could easily handle unless you spend the BIG BUCKS for the extra small needle hole JUKI feed dogs. The 246, when not setup as synchronized binder, uses an elliptical style feed dog (NOT just back and forth) but more an oval shape. As synchronized binder it is simple back and forth motion of the feed dog. I believe the 1341 has the advantage of using a "four-motion" rectangular feed dog for slightly better control of bottom fabric though the needle cycle. On the 246, if you wanted to switch between regular sewing and synchronized binder, it is only a matter of 10min to swap all parts. If you use non-genuine juki parts, the swap is very much a reasonable cost. The pictured 246-6 is missing an item or two at first glance and top cover of cylinder arm appears misaligned or bent upwards compared to the throat plate. Both parts are easily replaced. As mentioned, the pfaff 335 is similar but both the pfaff and the juki have many different sub classes of those 335/244/245/246 models. Last year, Gary at Forsewing had a number of used 245/246's. Nothing listed on his site right now but might be worth inquiring with him. LA based but it was only $300 for freight at the time of quote.

-

She looks quite annoyed about it, too... I'm enjoying these cards you're doing. Thanks for posting them.

-

Singer 133k17 threading and stitch length adjustment

pierre2171 replied to sandyt's topic in Leather Sewing Machines

Hello I own a 133k13 jumping foot. I dont know how to set up the bobin to sew. Any help or manual available thank you. Its to repair jute bags -

Thanks. I also love lever guns. When I was a kid and my dad took me down to get my first hunting rifle, I chose a Winchester Model 94. Used, of course, but a great rifle. As to your wrap, I figured something like that might be the case. A bit of up front work sure makes the difference.

-

That little black guide is called a check spring. It's a very important part of the thread path. The "snap' you mention is the sound of the thread snapping behind that teeny little tab, visible through the oval hole next to the screw. If it's not snapping in, try holding the thread that's above the check spring so that it doesn't pull from the spool. At that point in your threading process, you could drop the presser foot. That will clamp the tension discs down and should hold your thread. Based on the angle of the thread coming off the check spring, it looks like it's behind the tab. I think.

-

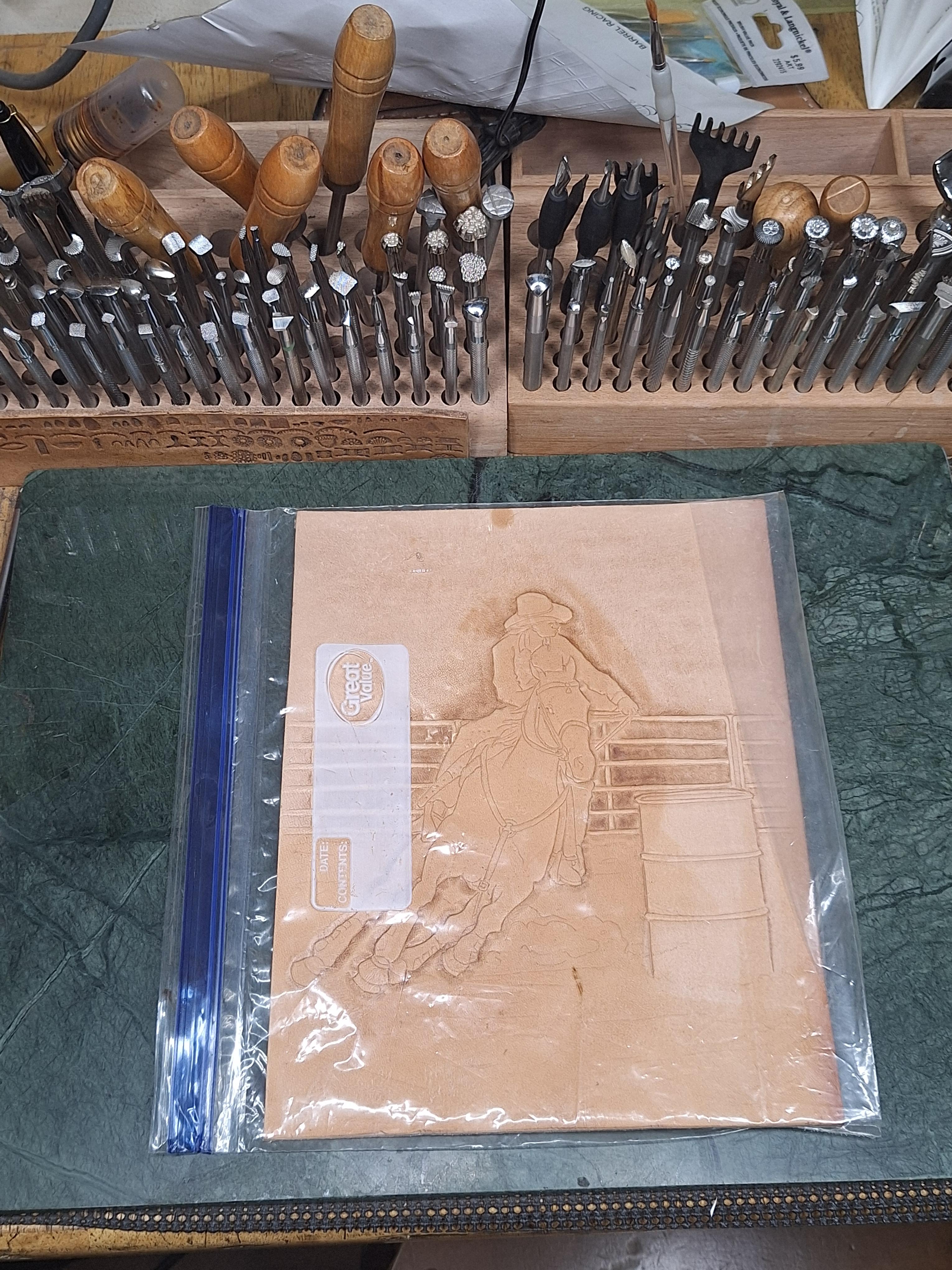

What's on the bench today? Barrel Racing, thought it would be fun to do a womans Western sport carving.

-

Is there a sewing machine for me?

Wizcrafts replied to D.jsherwood's topic in Leather Sewing Machines

You'll need a walking foot machine for this job. It could be a portable walking foot machine made by Sailrite. Or, it could be an industrial machine head mounted on a 20x48 inch table with a clutch or servo motor under the table. -

More experienced voices will no doubt chime in here but you should be able to get into a used machine with that budget. A tight budget, for sure and your may end up with a fixer upper, but doable. I'm thinking something in the range of a Consew 206RB-x (x being a number up to 5), or one of it's many equivalents. Start fishing what you find past the experts here and you'll probably get great advice. I'd only suggest holding out for something with reverse. You don't need it and not having it will save you money. But you'll experience a feeling of lack every time you use an older method to lock your stitches.

-

Hello all. I just joined here to ask you all gor advice on what machine to get. I dont have much, I really can only go up to about $650 on the machine itself, and I need it to redo a boat interior, so, vinyl. It seems as though each time I find one I think would work, I see one you all or folks elsewhere saying not to get it.

-

I was trying to figure out what might have caused the issue initially and it became clear very quickly when rethreading! So the little black guide photographed doesnt click as I am led to believe it should? So the thread gets wrapped around the disc after a couple of revolutions and the thread tension is far too high. Ive asked a lot from you already but do you have any further advice regarding this matter? Thank you all again, Merrick Sorry, photo attached here

-

first pancake holster

dikman replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice stitch lines! -

Awesome! 💃 Make sure the handwheel turns freely (easiest to check with motor drive belt disconnected), and that it forms stitches. If all checks out you can reconnect the drive belt and go back to stitching under power. The safety clutch may disengage again if too much load is placed on the hook driving shaft. Two things that will make it go much better for you: Start each seam with the take up lever at its highest position Hold the top thread for the first couple of stitches

-

what are you needing? glenn

-

I tie the knot between the layers then cut the threads as close to the knot as I can get with my utility knife. I don't use the knife to slice the thread in a cutting motion, but pull the thread against the thread so that they make the cutting motion. This helps avoid cutting the leather. If there is any little tag of thread still sticking out, just tuck it in, then hammer the seam.

-

Yeah, that's the vid I was thinking of. Or, just upsize the purse-size pattern to your liking.