All Activity

- Past hour

-

We got one at the Sheridan show last May. My wife has used it some. I played with it and thought it has some real possibilities.

- Today

-

The Tattool machine from Weaver Leather supply. Has anyone tried it? Opinions? Thoughts? There is always space for innovation, isn't it?

-

welcome back!!! That's nice work.

-

Not exactly creep but the ramp up speed is so slow it almost feels like it. The creep you mention is what I would call slip. With my motor and synchronizer, it's set up where I can get one stitch per tap on the treadle. I think buried down in the settings, I can adjust the speed as well. I don't want others to think I'm promoting one brand of motor, but if you search in my previous posts and then do a little research, you can find out more details from others to see the motor in action. After that, then you can make your own decision.

-

I have read on here that the brushed servos start from zero and have better low end torque. Verify this for yourself! I have a few brushless servos, one of which starts at 100 rpms. With a 45mm motor pulley, a 6"/2" speed reducer and the stock 3.5" machine pulley, I have a bottom end of 11 stitches per minute. You'd never really sew that low but it gives me a slow start with good control and torque. Still, the brushless motors increase in increments of 100 rpms, whereas the brushed versions apparently increase smoothly. When I need another servo motor, I think it'll be a brushed version.

-

Tomato-Ono joined the community

-

believe it or not - I run a JACK 563 servo (actually 2 of em) for many years and just recently I bought a fxcking cheap Chinese servo (for under 70€ few month ago incl shipping) and it behaves and performs way batter than the Jack - not kidding. It starts at 200 rpm and I can dial down to 100 but than it makes strange sounds. https://de.aliexpress.com/item/1005007257363563.html price on my side of the pond is 88.99€ now incl shipping (Warehouse in Germany). The Jack quality is better, thats for sure but this cheap sucker just performs better. I however have added a speed reducer too, better too slow than too fast and you still have enough end speed. But to each his own...

-

The main difference is a clutch motor is running at full rpm's (1450 or 1750) as soon as you turn the power on and like a manual transmission in a vehicle you ease the on clutch. The servo motors don't spin until you depress the "go" pedal. All servo motors have a "startup jump" with the brushless typically having a more noticeable "jump" then the brushed servo motors. You can reduce this somewhat by reducing the pulley on the servo motor, installing a speed reducer and buying a better quality servo motor. Typically the more internal coils the servo motor has the less "jump" experienced but check the startup rating of the servo motor a lot of the cheaper ones have a 500 rpm rating. kgg

-

Thanks for the info, does your new motor creep in like a clutch motor

-

1) change the motor pulley to the smallest you can find, usually 45mm 2) go with a larger pulley substituted for the handwheel 3) speed reducer 4) I tried 1 and 3 above, ended up getting a different servo motor that would start at 50 rpmand not 200 or 300, game changer -

-

Hi, I have a Brother LS-B837 industrial machine and added a sevo motor which is great apart from when starting to sew, the motor doesn't come in slow and smooth like the old clutch motor used to. When its running its slow enough but would like a smooth start instead of it jumping straight into the slowest speed which is quite slow. Does anyone know of a mod that will acheive a smooth slow start like a clutched motor does Thanks

-

Gram joined the community

-

What Age Is This Simco?

Gram replied to 1nicesimco's topic in Saddle Identification, Restoration & Repair

I have this saddle. It belonged to my aunt. She gave it to me when I got my pony in 1973. She got it for Christmas in 1955-57. -

I would reconsider by the time you change the clutch motor out for a servo barring anything else you are up to about $1100 for a machine that came to the market in 1976. If you need parts they are going to be either hard to fine or expensive. Since you mentioned the Consew 226 which came to the market around 1960 I would go more for a newer Consew 206RB-5 which has a larger bobbin and costs about $1800 new. kgg

- Yesterday

-

The tooling in itself has stiffened the leather by the compression from stamping. Alcohol will dry it out a bit adding to the stiffness, so will dying (it contains alcohol). Use NFO or mink oil to condition it before dying. It will loosen up a little on its own over time and with use. Don't overdo the oil. Any oil or conditioner will darken the leather a little bit. It looks darker right after application then lightens some. That's all in the nature of leather and you will learn to work with it.

-

Fender repair...

chuck123wapati replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Good luck man, you got this!! -

I have been making holsters, sheathes, pouches, belts, etc. My daughter came up for Christmas, and dropped a new project on my bench. One of her friends has an old saddle she loves, and her fenders are badly worn. "See if you can redo the fenders," my daughter said, "the attached stirrup leathers should be fine." The fenders were tooled in a basket weave pattern. "Nope, she'd actually rather lose the basket weave, it's been eating up her legs for years. A border would be okay." This will be a new experience. Break down the existing pieces, saving the parts that are still good, and the hardware. I ordered the saddle skirting weight from Makers, and the heavy rivets/burrs plus the setter I'd need. Looking forward to the challenge. The owner knows I've never done this work, but has seen my tooled belts and sheaths. I have my wife and daughter to advise me. Both have years of equine experience. Waiting on UPS. Wish me luck.

-

hello I have some undyed vegetable leather, got cut and tooled, to me feels stiffer now. my questiion is what can I use to soften before i dye? I read can use mix of rubbing alcohol with vaseline, mink oil or neatsfoot? what does everone use or find works best, for hoping not to darken leather.

-

roman_v61 joined the community

-

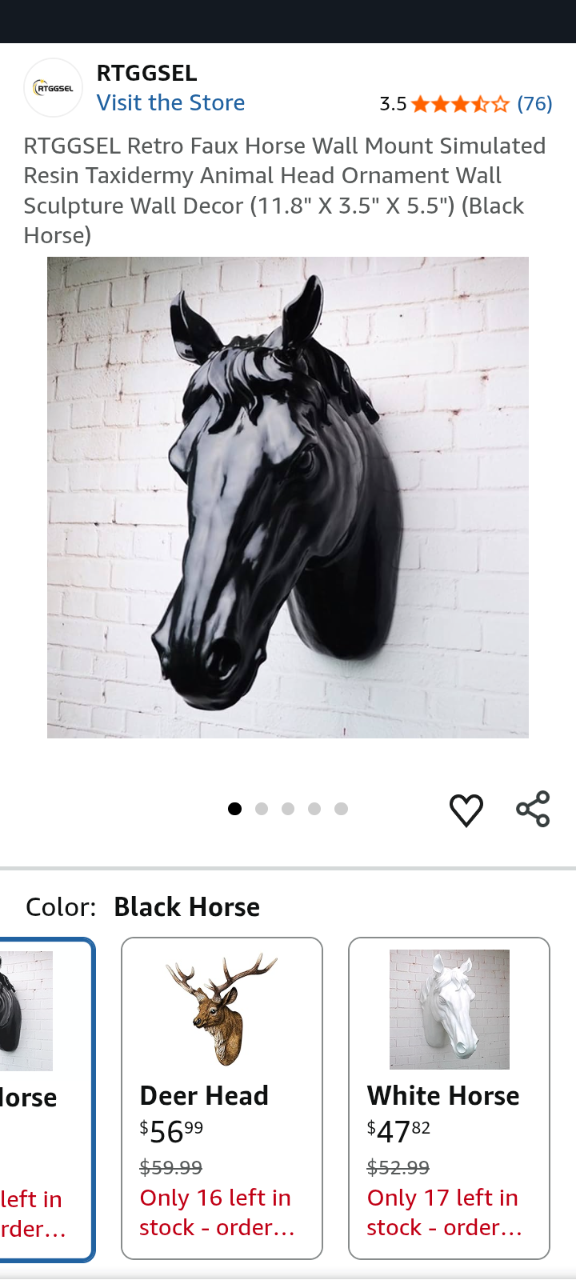

As the title says, I'm looking for a way to display several headstalls, halters, hackamores, etc. Ideally something that can hang on the wall or somehow arranged in front of a saddle stand display with a plackard nearby explaining the what and why. I've found several places that sell plastic or fiberglass busts of horses heads, but often at $300+ and that will add up quick doing multiples (anywhere from 5 to 20 depending on how far I go). I'm wondering if anyone else has done something similar? I would actually prefer less detail so it doesn't detract from the displayed item, similar to mannequins in a department store, but It still needs to be life-size and have some form of mouth, ears, jowls, and everything else that would play into a headstall properly fitting a horse. I'm looking at 3D printing them myself, but the size makes that a challenge. Also considering a very very simplified wooden frame or lamination that again has the important area's but lacking detail. Almost like the heads used on steer roping dummies that have horns, but are not a fully modeled cows head. The alternative of course is hanging them on a hook like you would in any tack-room, but being able to see how it fits and why pieces are where they are is the real intent. This is more for educational display than for storage.

-

I use Ballistol on my rifles and pistols, it's a great product, but I wouldn't use it directly on my holster. You may get some transfer from the weapon to the holster but I'm guessing it extremely minimal if you use it as intended. I use NFO on all my holsters and customer's holsters and never had an issue. Again you use it as intended and you shouldn't have a problem. I'm sad to say I did this to my first cowboy rig and I paid the price. I grit my teeth each time I look at my revolver.

-

freders0 joined the community

-

Looks great! I made two Kangaroo Hide Bullwhips and I really enjoyed the learning process that came along with it. I got a LOT of help from Bernie Wojcicki a few years before he passed. He was such a great guy. I never got good or efficient at it, but it was fun. Bernie's videos can still be found on Youtube I think under Bernie46......

-

Hi, I'm a long time lurker, but I don't remember introducing myself. About 6 years ago, my husband and I bought a boat cover canvas biz. With it, came a Singer 531B-8BL/Consew 206RB-2, a Adler GK373-67, industrial machines, and a patcher Adler-30/Singer 29K71 [or similar]. I was sadly mistaken that the elderly couple would help train me with the machines, and it didn't happen. I was lost until I found this site. The members helped me find manuals, etc. I was especially excited when I learned that my machines are built for leather. When we picked up the patcher, it was covered up in a dusty corner, and I was told that it didn't work. Thanks to the info I found here, I was able to clean it up, and get it going. I love that machine. I've repaired ball gloves, purses, and used it to sew patches onto the g-kids letter jackets. Last year, launched me into leatherworking. My firefighter g-son asked if WE could make a leather radio strap together. Well, that WE project ended up being totally me. It was an experience, that's for sure, but I loved it. So, my attention now, is leaning more towards leather work. After I posted a picture of the strap, a friend has asked if I would repair the rope/braid on her leather bag. I am thrilled that this website has been updated. I'll be looking for help with the bag project. Thank you, admins, for all of your work. I am so excited to be back!