All Activity

- Past hour

-

I would get a wire brush and scrap all round the unit particularly around the feed eccentric seam and then add a few drops of good old fashion diesel around the feed eccentric seam. Wait about 24 hours to let it soak in, a few light tabs with a hammer and without any needle or bobbin run it at different speeds for a few minutes. If it hasn't freed up start over with a few more drops of diesel. Once freed oil the heck out of it with some synthetic transmission oil. If you can't get it freed like @CowboyBob has suggest replace the unit. kgg

-

Frozen Stitch Length on Singer 144W103

CowboyBob replied to friquant's topic in Leather Sewing Machines

There's 2 ways to fix it,replace it OR try sewing & using it w/o locking it up should make the part rock in the grooves to get it to free up,you need to tighten the smaller screw since that is what connects the stitch cam to the shaft. - Today

-

Great work! I love those closures on the tracker sheath.

-

Looking good. You are right. Hard to hide any nicks, fingernail marks for sure.

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

@chuck123wapati you've convinced me, i'll give the ol bunky bbq a rebuild . Our spam comes in a nicely formed lump out of a tin and can be sliced, just like corned beef in a tin , full of fat and God knows what else, a vegos worst nightmare, that and black pudding, ha! But they taste great 👍 HS -

Machinerist7 joined the community

-

What’s the maximum thickness the Singer 29K71 can handle

JRodriguez replied to JRodriguez's topic in Leather Sewing Machines

Thanks everyone for your input. That is definitely very helpful. cheers, José -

-

Funny, but gosh, that looks OLD! Is it from an old movie?

-

You need to quote part of the post, or tag the user so he gets a notification. @szeregowy You have some one interested in your machine. To tag a user, type the @ symbol followed by the username, then pick it from the popup box.

-

12 year old post, but @BearManappears to check in still. Maybe tagging him will draw his attention.

-

Best source for clicker dies?

wizard of tragacanth replied to wizard of tragacanth's topic in Leather Tools

Hey Cumberland, Thanks for the recommendation, and the heads-up. Yeah, I figured that Weaver had a premium price on their champagne product but I'm on a beer budget! Nick -

Best source for clicker dies?

wizard of tragacanth replied to wizard of tragacanth's topic in Leather Tools

Hey Bruce, I'm so glad that you mentioned Texas Custom Dies. I bought a bag punch from them maybe 15 years ago, give or take but I couldn't remember their name. I was (am) very happy with their product and service. I will likely go with them this time... no reason not to. Nick - Yesterday

-

So was I right?

-

Jjp joined the community

-

Can you make another?

-

Frozen Stitch Length on Singer 144W103

friquant replied to friquant's topic in Leather Sewing Machines

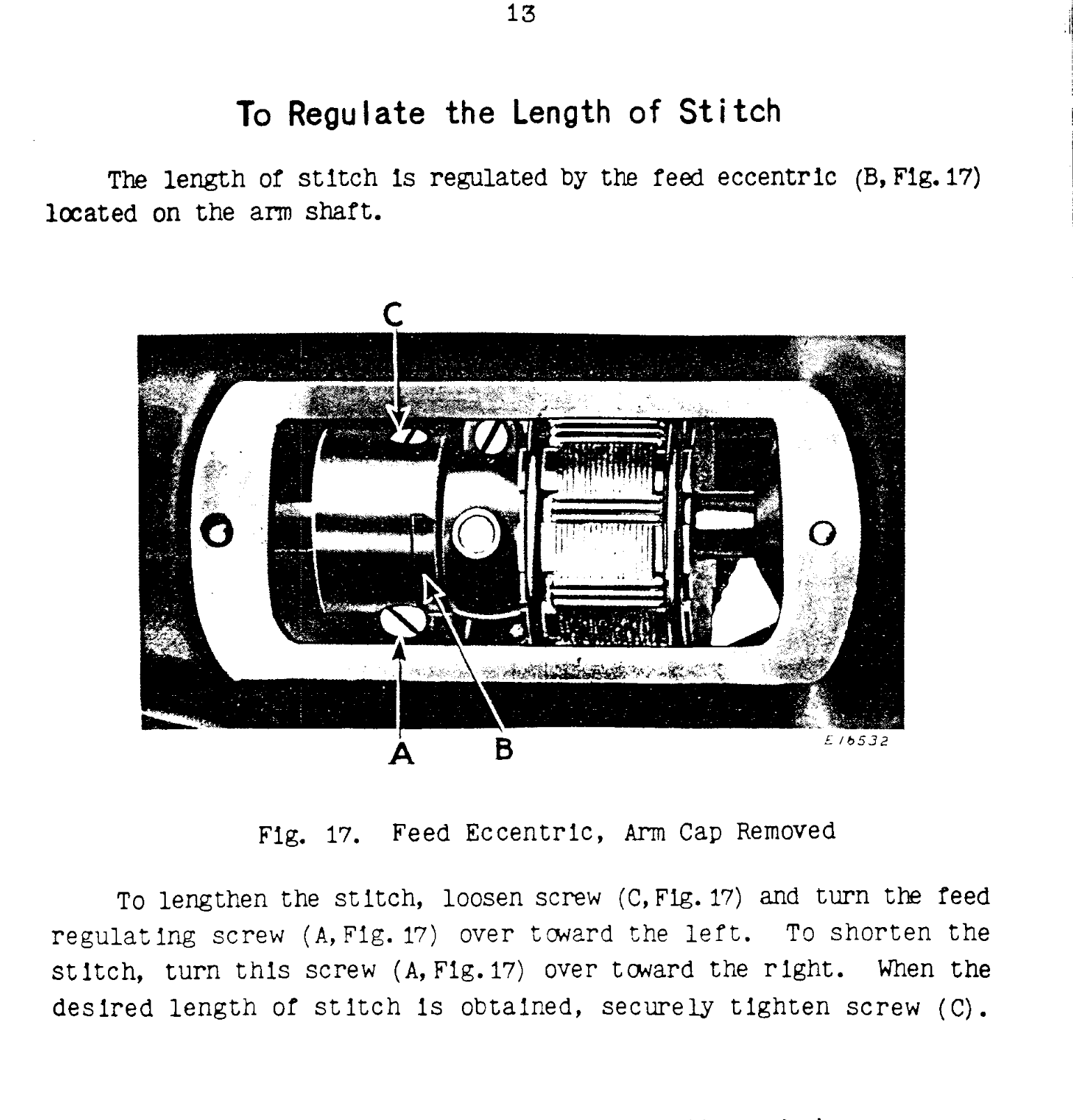

Here is the relevant section of the manual. I assume that turning the adjustment screw clockwise is meant to bring the ex-center closer to the center of the shaft. -

The bobbin case isn't fitted properly, that tab sticking out is supposed to fit in a notch under the needle plate to stop the case from turning.

-

Did the problem start straight after you damaged the cable? It's a bit of a coincidence if that's not the cause. IF that's the cause then the chances of getting a warranty claim is unlikely. As far as the manufacturers are concerned these things come under the category of "disposable/non-repairable", I've never heard of anyone carrying spare circuit boards for them. Much like the speed control boards in mini lathes, mine died pretty early and the Chinese company offered me a partial refund as they didn't carry spares. I eventually sourced a speed controller on ebay and adapted it BUT I doubt you could do that with a servo. I agree with kgg, if the board is damaged then the simplest/cheapest option is to buy a generic servo off ebay unless the dealer is willing to help out. As Al said no-one appears to have bothered doing any work on these (probably because there's zero information available about them!).

-

I assume you removed the hook. When you drop the hook back in, make sure it also drops into the hole of that little piece that moves the bobbin latch opener. If you miss that part, the hook (and bobbin) will be about 1/8" too high, and the screw won't tighten reliably because the hook isn't down where it's supposed to be. It's important not to run under power till you get this sorted. A check for this would be to turn the machine over (gently) by hand and see if the latch opener moves. If the latch opener does not move, then the hook probably isn't down inside that piece. I don't remember exactly what mine looked like that had this problem. This machine Uwe demonstrates on looks more or less foolproof, but I've had a different machine that was quite fiddly to get all the pieces to align so the hook would drop in all the way: https://www.youtube.com/watch?v=CfkGrz3OugA&t=277

-

Have you tried unpluging the servo motor cord from the wall outlet. Some electronic items even through you have the power switch in the "OFF" position they are still drawing power and are basically in a "Sleep Mode". I would unplug and wait a few minutes just to make sure it has fully powered down and cleared it's memory. On my LS-341 clone which has a brushless servo motor and electronic control when I throw the power switch to the "OFF" position the electronic display stays light for about a minute before going blank. So there is a power draw. I would contact both the store and Artisan to clarify your warranty. Having a damaged cable could have or is causing a short which in turn could have caused an error or worst case fried the controller. If you damaged the wiring chances are you are going to be on the hook for a new cable and possibly a controller. If it does turn out to be the controller unit it maybe cheaper just to replace the complete motor setup for about $150 to $200 for 6 coil motor or $300 for a 12 coil motor or a brushed servo motor for about $175. The trouble you are having tracing the source of the problem highlights the difference between a brushed servo motor with no fancy electronics and a brushless servo motor with a electronic controller box. As you can tell I am not a fan of the brushless servo motors. I like my machines to be as simple as possible. Sewing machine, speed reducer (on some), servo motor, drive belt(s) and a go pedal. The two machines with brushless servo motors have the needle positioning disconnected. kgg

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)