All Activity

- Today

-

@OscarRush Sewing those thicknesses of veg-tan leather are beyond the scope of upholstery class walking foot machines. You'll need to buy a machine that's built to sew holsters, saddles and horse harnesses. Most of these machines can sew at least a half inch of hard leather. Some, like the cb3500 and 4500 that AlZilla mentioned, can sew 7/8 inch of saddle skirting. I have the 4500 and a bunch of walking foot machines, so I know what I'm talking about. My walking foot machines can sew up to 3/8 inch of chap or garment leather, using #138 bonded thread. My Cowboy cb4500 can sew from just under 8 ounces, up to 52 ounces thickness with very heavy thread, like #441. I personally never go beyond #346, but I could if I needed to.

-

Take bobbin assembly out of 1341 cyclinder arm

TonyD1948 replied to TonyD1948's topic in Leather Sewing Machines

Thank you -

Thumbs-up, Chuck!

-

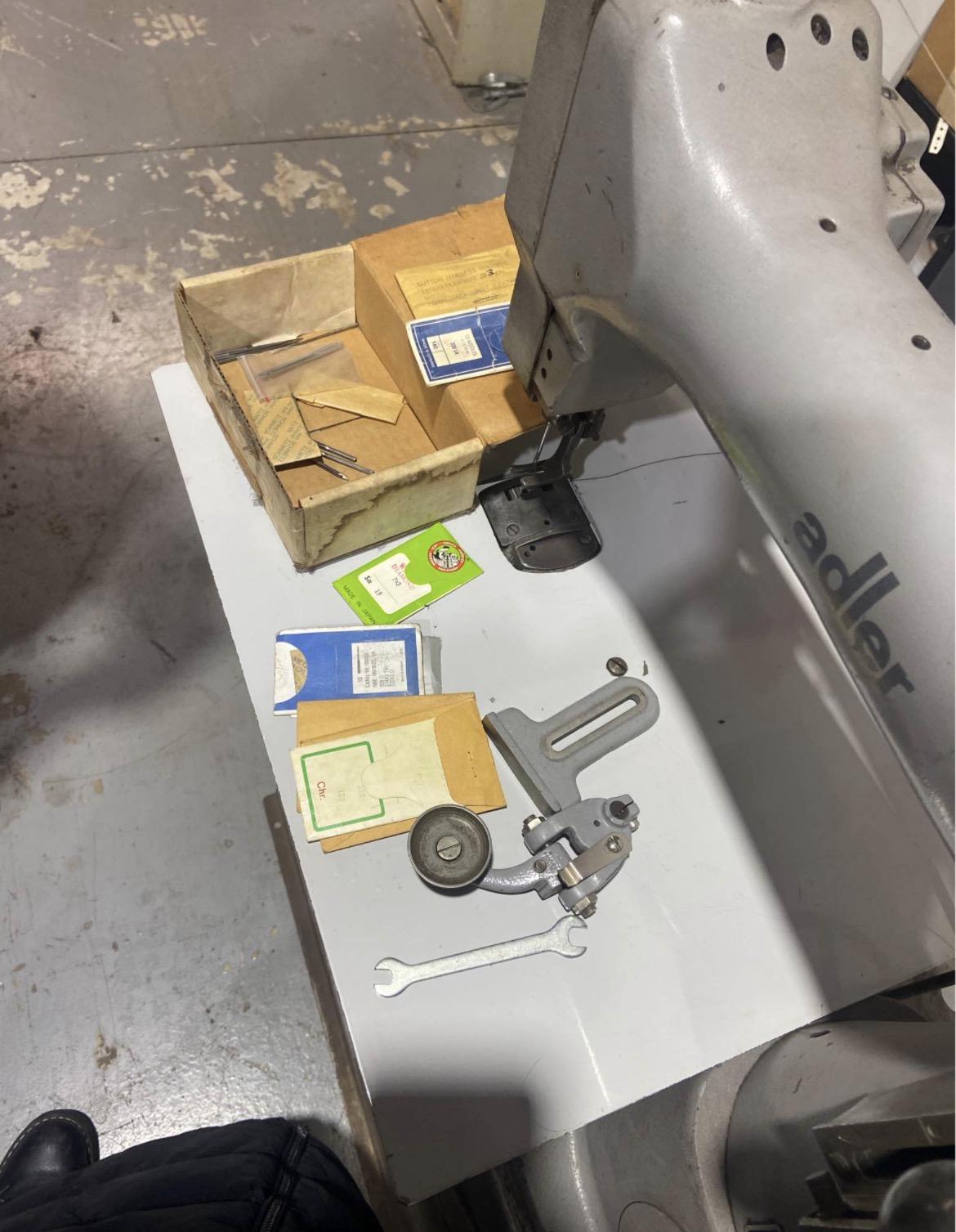

yes - Adler 105 - 64 subclass, needle feed machine with heavy roller foot!

-

I've also been getting into this weave pattern. I'm having trouble w/ free handing the pattern- esp the spacing to size up for larger weave sections (eg. for a bag panel). I've downloaded the various paper templates but looking for an acrylic one that I've seen w/ the Wuta wallet and others. Any luck by others finding a better template? Thanks much.

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Yup, they do that a lot here as the temps get into triple digits. I've watched a lot of his stuff over the years. Excellent instructor, even via you tube where you can't ask questions. -

-

I use single action airbrushes as I just couldn't get the hang of the double action airbrushes, like the Timbertech Airbrush Kit and the Paasche Airbrush that are siphon feed rather then gravity feed with the braided nylon hoses. I would push the pressure probably up to 40 - 45 lbs from my normal of 30lbs. You may have to: i) use a real compressor rather then an airbrush compressor just for the volume of air that maybe required. ii) detail spray gun like the Titan Tools Siphon Feed Detail Spray Gun if the consistency in doing the large pieces isn't what you need and to reduce the number of dye bottle changes. The airbrushes that I have can realistically hold about 20ml while the detail spray gun could probably hold close to 200ml. I have done 2' x 2' pieces of leather using my airbrushes with the airbrush compressor for both oiling (JOJOBA oil) and dying. I would definitely try the inexpensive Timbertech airbrush first, practice on a piece of cardboard of the same size first to get your spray and your rhyme right. This topic on my setup may help.

-

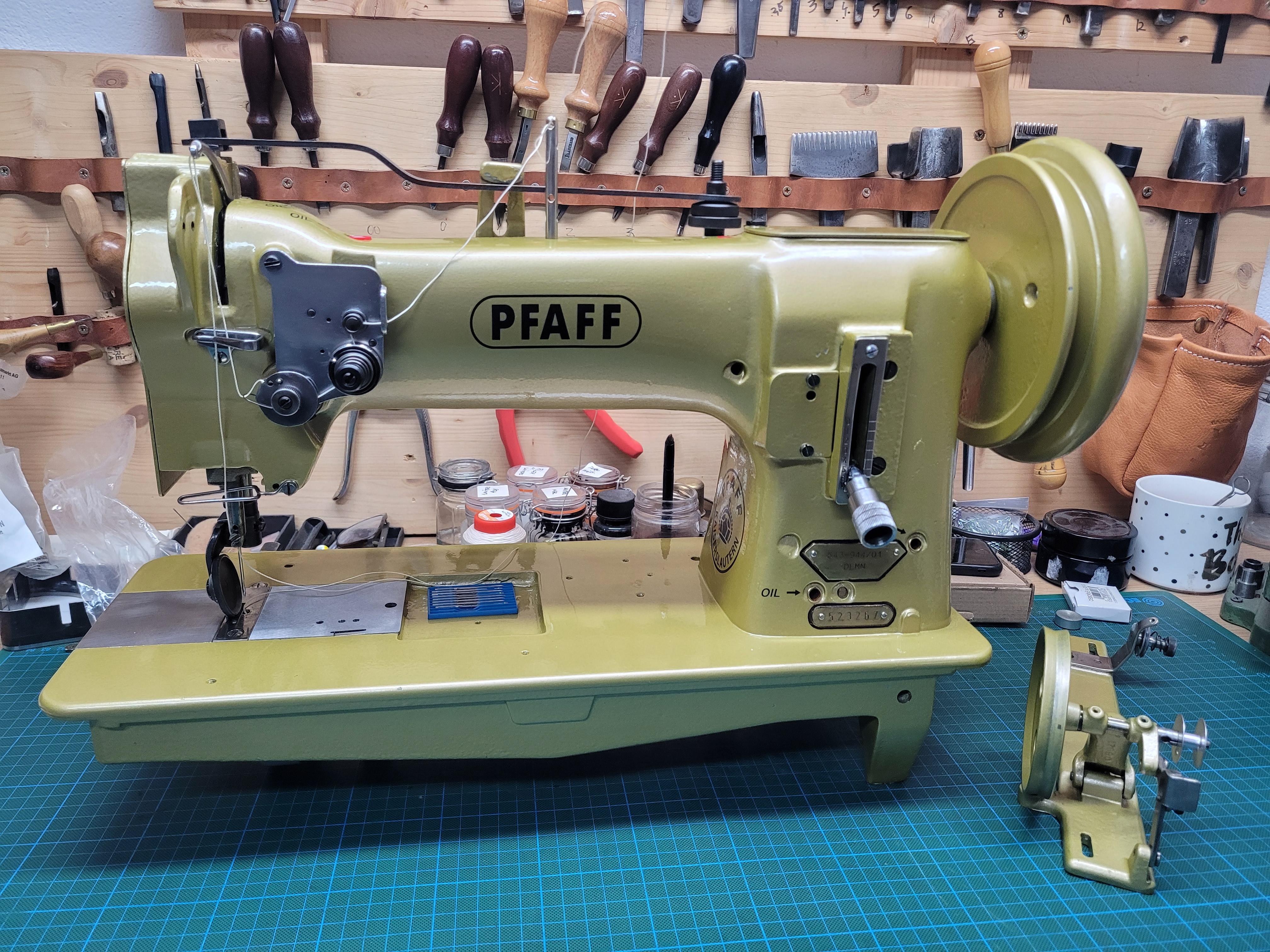

You've done a beautiful restoration on your machine! I have a gently used 545 that I think is a wonderful machine. I'm surprised that you found the parts for your modification, I rarely see anything for Pfaffs. Where did you find the decals?

-

I ve found it locally in Romania. At a mechanic

-

Take bobbin assembly out of 1341 cyclinder arm

kgg replied to TonyD1948's topic in Leather Sewing Machines

Before attempting to removing the bobbin assembly I would remove the bottom cover on the cylinder arm as you have a 50/50 chance that the tip of the needle fell down there. kgg -

Others will be along, but 12mm is pretty close to a half inch. I'd be looking at something like a Cowboy CB 4500. I'd think you're using pretty thick thread. I think the CB3500 is the same machine just with a shorter arm. Known genetically as a 441 clone, if that brand isn't available in the UK, something just like it is. Plenty of other capable machines but that's the one I'm most familiar with.

-

Have you looked at the PDF attached to the first post? That seems pretty generic to me. You just need the measurements of the rifle in question. Maybe I'm not understanding something.

-

This topic wouldn't really "close". That's mostly for the For Sale section. Maybe tell us where you found it to help out the next guy looking for one.

-

That’s a beautiful machine. I just got a cb341 and our machines are very similar. Congrats and have fun man!

-

Found it! How can I close the topic? Thanks

-

I checked out a couple of YouTube videos. seems its a little hammer-like deal that just puts down the impressions then uses regular acrylic paints to color the impressions so its not really anything like a tattoo at all. No ink under the skin. Kind of gimmicky if you ask me, BUT its a way to learn, use and gain some real artistic skills and would look better IMO than a cut and paste laser image no matter how well executed. Sorry folks, I'll take the human effort over machines any day. If money weren't an object i would probably try it out but it is so i might try to recreate the idea with homemade tools. LOl a thick pointed stylus and a mallet. LOL after I wrote this i searched YouTube again, there is a video on how to make one out of a 60 dollar tat gun. so if you have the urge to try and don't want to spend a lot of money.......

-

Hi guys, In case anybody needs this info. On my 543 DLMN, I ve added needle feed. I made sure the bushings are there, and then you only need the needle frame rocking shaft and its linkages to the forward movement shaft,parts from a 545 and to increase the slot in the needle plate. My issue was that with the rubber coated feed dog and presser, the machine couldn't feed oily leather. Now it works beautifully. https://youtube.com/shorts/rnloVTpOTMM?si=CJgy8PEpiT6QMeQO Probably same scenario can be applied to Pfaff 143. The machine was completely rebuilt by me at the beginning and it is stitching beautifully my belts and notebook covers. It can handle thick threads, upper and bobbin, compared to my 169 Adler. Pics are from the rebuild. The parts for the needle feed were added after everything was assembled. A bit of planning needed but it went ok! Cheers, M.

-

Fender repair...

chuck123wapati replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Don Gonzales has some videos on saddle work if you use you tube. -

Singer 211G156 vs Seiko STW-8B (Consew 226R) for heavier thread.

beefy replied to beefy's topic in Leather Sewing Machines

Ah, is that so. Thanks for letting me know. It makes me feel a lot better because I didn't know the K6 was not a unison feed. Put that together with no reverse and it looks a lot less attractive. So that "loss" turned out to be a blessing in disguise. -

Singer 211G156 vs Seiko STW-8B (Consew 226R) for heavier thread.

beefy replied to beefy's topic in Leather Sewing Machines

Cheers AIZilla, I do a little boat fishing and there's these things called sea anchors or drones. They are a conical tube, and I was wondering how the hell would I stitch one on a flat bed machine. The post bed machine seems like the perfect machine for that type of thing too. Also looks like it would be easy to add a platform around it if I needed a temporary flat bed machine. -

Singer 211G156 vs Seiko STW-8B (Consew 226R) for heavier thread.

beefy replied to beefy's topic in Leather Sewing Machines

Thanks Dikman, come to think of it I've never seen a used really heavy duty machine for sale, except through a dealer. -