All Activity

- Past hour

-

I agree veesee, it does look better but I have to be honest and say that with more practice, you can get better. There are gaps or voids between the layers in some places. I am not sure what is creating this. It could be the type of glue that you are using, not using enough glue or not applying enough pressure after gluing... I'm just not sure. It could be the leather itself. I have had crumbly leather that looked like that. You are at least half-way there. Glad to see your effort. It's definitely an improvement. What type of glue are you using?

-

Leatherman sheath

rktaylor replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well done. Randy -

I use poundo board or scrap leather.

- Today

-

Hand-cast solid Brass Buckles from a small foundry

Dwight replied to Origibelts's topic in Suppliers

Just a curious question . . . if someone was to send you a "pattern" . . . made of plastic . . . cut out on a computer based machine . . . of an exact personal buckle . . . would you be up to making that buckle? I'm thinking of the American Western buckle type . . . May God bless, Dwight -

Well, KGG pointed out that your needle is in backwards. It's a wonder it stitched at all! You're definitely inside the 5 yard line but those last couple yards can be a grind. Spin the needle around and see how it goes. It's got to help. And It seems that the needle isn't well centered in the hole, so you'll want to address that at some point.

-

I've been ordering belts from amazon. Here is an example: https://www.amazon.com/uxcell-Classic-Wrapped-Outside-Circumference/dp/B0DR767RWV You can also get them in white: https://www.amazon.com/dp/B0BK1FQHRR Other options include adding a wooden block between the table and the motor (a spacer) so you can use the longer belt. This may require longer bolts though. Or 3D printing a larger machine pulley, which has the added benefit of slowing it down and increasing torque. Lots of folks have swapped clutch motors to servo motors. Any particular questions you have about the swap?

-

How are you and the machine doing? You mentioned a tension issue. Once you start holding the top thread when you start a seam, if there are still loops on the bottom then you need to add more top tension. I should have mentioned that before.

-

Repair of leather edge on Louis Vuitton bag

PrePro replied to Mulesaw's topic in Satchels, Luggage and Briefcases

I'm about to attempt the same thing - may I ask, what thread did you use and do you recall the brand/color of pigskin? I was going to try kangaroo for strength and try to get the color to match but best to go with the original. thanks for posting! -

It seems to me that the internet is full of "experts" on nearly every subject these days. JM2C, Jim

-

The sept/Oct issue of the learher crafter's journal had this neat little sheath by Gabor Pinter. I thought I'd have a go at it.

- Yesterday

-

Does anyone know what this black material is, and where to buy it? I'm making a couple dozen briefcase inserts, and I need some kind of backing for stitching pockets. The ones the customer has today have a black backing shown here, that feels like it has an almost plastic feel to it. This is the sample they gave me, and I'm supposed to make something similar. I've tried bookbinder board but it needs another backer behind the backer - like leather scrap. So that's extra cost to glue a strip of leather to the book board, and extra work. It's also not ideal in case someone drops a drink on it. Thanks!

-

- what is it

- backing

-

(and 1 more)

Tagged with:

-

Hi everyone. I'm new to the landis 3. Just got one last week. I'm trying to stitch some harness traces that are about 5/8" thick. I want to move the presser foot up in height a bit. Does anyone here know how to do that? I have a manual and it makes no sense to me. I've gone over it so many time now my brain hurts. I simply can see anywhere on here for adjustment. Thanks for any help on this. Brian Merrick

-

Interesting. I thought dog fanciers are a friendlier bunch. Perhaps it’s a sign of the times.

-

-

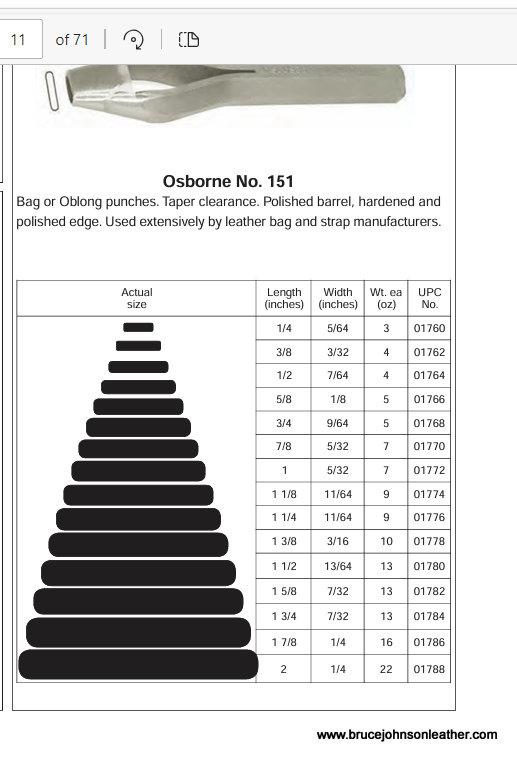

There was discussion recently which included talk about large oval punches for holsters I can't remember where it was or by whom, but if I find it I'll post a link edit; check this thread out

-

I moved your post to leather sewing machines

-

I moved your post to leather sewing machines

-

I know nothing about horse related items other then to say the workmanship is very nicely done. I see the same type of "cranky" comments about prong collars for dogs. kgg

-

I usually make bridles with a simple cavesson noseband - a continuous strap of leather and the buckle off center under the chin. This bridle has a Swedish or crank style noseband that evokes strong opinions. The crank is two-piece construction with a padded strap that can generate some leverage when tightening the noseband. Proponents say that the crank style provides flexibility and even pressure under the jaw. Critics note that the crank lends itself to overtightening, causing discomfort. The name "crank" is a rather unfortunate choice. I posted the bridle on social media and sure enough some of the comments were "cranky." Maybe there's no such thing as bad publicity? I enjoyed making this noseband but the construction takes considerably longer than a simple cavesson. At least I have the ability if someone asks for one.

-

Very little MDF contains formaldehyde noawadays. Exterior grade MDF has less than 1% and unless its been sitting for over a decade, the remaining 3 grades should be formaldehyde free. Dont know if what he got was neoprene or rubber, but the gym matting @dikman mentioned leads me to my suggestion of conveyor belting, or skirting rubber Its a bit on the pricier side but its usually a natural gum rubber and extremely durable, and dulls abpot the same as the delrin/poly cutting boards.

-

Belt extension, tooled English bridle

BlackDragon replied to DoubleKCustomLeathercraft's topic in Show Off!!

Yes AND you can cuss out your leather all day long without repercussions.- 12 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Belt extension, tooled English bridle

chuck123wapati replied to DoubleKCustomLeathercraft's topic in Show Off!!

I've lengthened plain belts with this method, but not belts with names centered in the back. Won't this throw that off a bit, or does it matter? You did a great job of itt!!- 12 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Belt extension, tooled English bridle

jrdunn replied to DoubleKCustomLeathercraft's topic in Show Off!!

People are WAY harder to deal with than leather! JM2C, Jim- 12 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Looking to further tighten up details on leather holsters I build. I'm getting by currently with a round punch and a slightly too narrow oblong punch but would like to do this in one or two hammer blows. I normally build holsters matched with either a 1/4" or 5 1/16" belt. Could someone direct me to a good quality punch that will make the slots the size I need in one pass? I've looked at Osborns but haven't been able to determine the width of the slot they cut. I expect to pay a premium price so long as the punch is great quality. Thanks.

-

Belt extension, tooled English bridle

PastorBob replied to DoubleKCustomLeathercraft's topic in Show Off!!

Agreed. I normally have them bring an old one to my shop or have them send pics of the belt with the tape measure on it. This would be good for modifying existing belts though. So far, I have only modified them to make it shorter, not longer. This would be a way to do it.- 12 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)