All Activity

- Past hour

-

Railed sig 1911 bbq rig

Stetson912 replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Haha, thanks. I personally like no accessories. Maybe a red dot or something would be ok. - Today

-

Stunning work! Your meticulous care to detail is awe inspiring!

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

I like it!! The expanded metal may be a trifle newer than medieval lol. heck yeah clean it up and season with oil. -

Singer 29k58 needle timing issue - I think.

Constabulary replied to LNB's topic in Leather Sewing Machines

I meant the shuttle driving lever 😉 but I guess you know what I mean. -

Just my two cents, but here's how I see it. I've shot a lot of bp and been around bp folks. They are particular about their sport, they do it for a reason. You say this fellow is a collector and real bp buff. Well then i would scratch a big no about fixing this with plastic of any kind. I can tell you now he probably wouldnt like it. His double barrel is probably worth about 3 grand or so and he hunts and uses it specifically because it is a reminder of the past, he can buy cheap crap on the net, but he chooses not to for a reason. My advice is still thicker veg tan around the nozzle. I think it will actually be easier than plastic in the long run and will retain its shape if you seal it well. Taking the easy way out may shoot you in the foot on this one. Collectors are picky folk. Bp folk and their accouterments are in an era that didn't include plastic lol. Either way small shot and black powder will build up between the funnel and the leather if you don't glue it or get a really good tight fit and good luck on your project!!!

-

Railed sig 1911 bbq rig

akguy59 replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is beautiful! Tell him that he needs to pimp his Sig a bit, because that holster makes it look too plain. -

Singer 29k58 needle timing issue - I think.

Constabulary replied to LNB's topic in Leather Sewing Machines

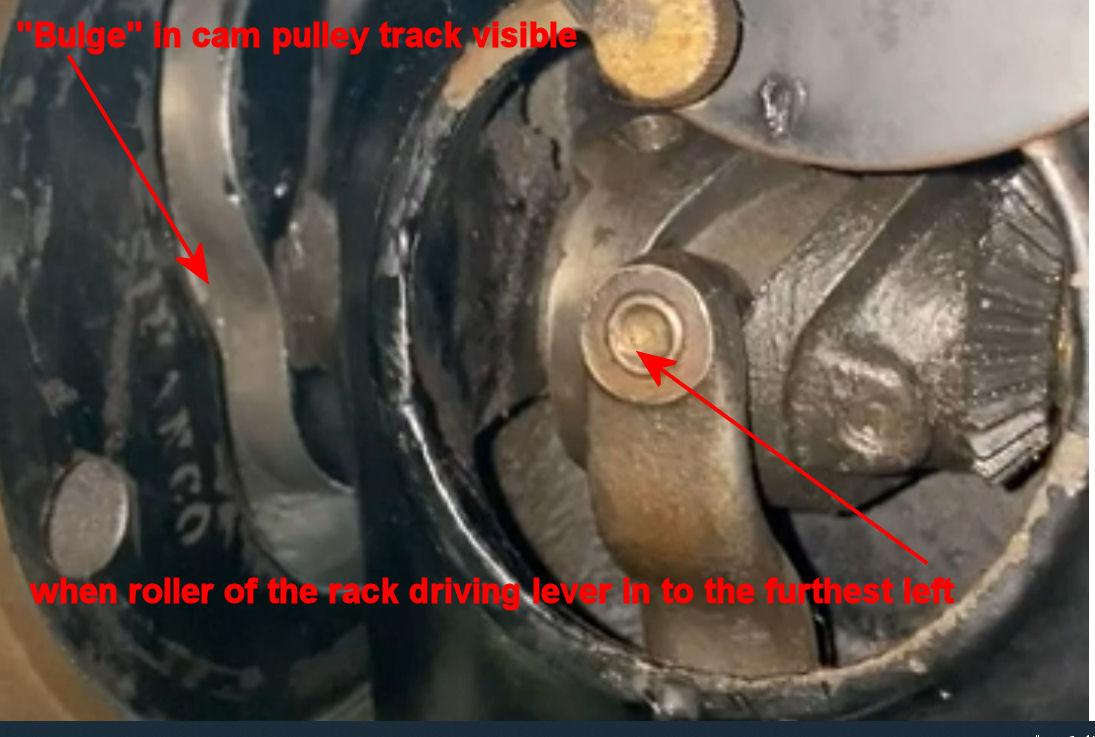

quoting my self 😉 When I look at the 1st video I notice that when the roller of the rack driving lever and the inner cam track are to the furthest left you can see the "bulge" of the cam track of the cam pulley - know what I mean? in contrast to that - when I look at my 29K71 cams (almost the same as yours) it seems to me that your cam pulley has been installed incorrectly - rotated by 180° as it seems. When I can see the bulge in the pulley cam my roller is furthest to the right. This is when the roller is furthest to the left: Do you see what I mean? -

Singer 29k58 needle timing issue - I think.

Constabulary replied to LNB's topic in Leather Sewing Machines

Have you read the manual? There is an eccentric for adjusting the needle hook timing. Just checking - have you taken off the pulley cam on the right end of the machine that governs the up and down movement of the arm lever which is attached to the needle bar? -

Ufrein joined the community

-

BTW - what I figured today is that the A51 ex factory is a "button covering machine". Not sure what you want to do with it but the Co. still exist and maybe worth checking with them: https://www.astor-berning.de/fashion/fashion-maschinen/187/a-51-knopf-ueberziehmaschine

-

Pictures of my lever press - its fairly a beast compared with "plain spindle presses". I needed an M10 (male) x 1/4 (female) adapter to make it work. Meanwhile I figured this must have been the manufacturer of my press but back then no data were available. https://www.loxx-produkte.de/live/Historie-Unternehmensgeschichte/historie.aspx But I doubt any spare parts are available anymore. Anyway I´have what I need and this thingy will last for ever. I have never seen a 2nd press like this either.

-

Hello By way of introduction, I am very new to leatherworking, and to using and maintaining bootpatchers. I have cleaned up a couple of SInger 201s and use a Featherweight 222 as my every day sewing machine. So I guess I am accustomed to Singers a little. Very aware I am a debutant in this realm. I have been cleaning up an Singer 29k58 over the last few months. I have stripped it as far as I could, cleaned it, replaced parts as needed and reassembled it. I was not able to take out all of the moving mechanisms - so the shaft, shuttle driving and needle bar cams. I cleaned them as best I could from the access I could get. Having reassembled it, I have two problems that I think are related. The bobbin timing is not right to loop the needle thread as it seems that the needle rises a little soon, and there is a pronounced clicking sound as the machine is worked. This should be apparent in the videos. I have checked and rechecked the racks and pinions in the rack box and adjusted the shuttle carrier as advised using the eccentric stud. I am wondering if the shuttle driving cam and the needle cam are not aligned appropriately, which is causing the sound and the needle to raise a little ahead of the shuttle carrier. Does anyone know if there is an appropriate way to align them and, if so, could they share that with me? Or am I way off in my theorising? I greatly appreciate the advice and wisdom I've been able to access from this community, which has got me this far. Hoping someone can see something I am not. Many thanks, Lisa Singer29k58 cam movements 4.mov Singer 29k58 shuttle carrier and needle 4.mov

-

Good morning! I thank you for your words!

-

It works with a simple mechanism. Elegance is sometimes found in simple.

-

Thanks for sharing those projects. I'm amazed and inspired.

-

Okay, that last bit I don't believe! He'd have to be a very mean cop to give the pilot a ticket for an emergency landing!

-

I do not know ASTOR but usually the threading for the upper die is either 1/4" (UNC) or M6, at least on the presses I worked with. I once restored two very vintage unknown brand presses with odd threading for a friend and on both I was able to replace the inner part that holds the upper die with a plain round m6 long nut (Gewindemuffe or Verbindungsmutter as it is called in Germany). So he can use standard M6 dies. https://www.ebay.de/itm/165996998186? The outer diameter was the exact same as on the die holder it required tinkering but both presses worked w/o problems. For my own press (I´ll post pictures later) I also needed an adapter but he company I bought from (IIRC it called IX-Trade or so) no longer exists (a way different press anyway) as it seems but there are some CO's . in Germany that sell different adapters, not sure if there is one that suits your needs: https://www.jstrading.de/de/pressen-oesen-zubehoer/Zubehoer/ or this one, they even mention ASTOR: https://www.getmore-shop.com/epages/61848837.mobile/de_DE/;ClassicView=1?ObjectPath=/Shops/61848837/Categories/Presswerkzeuge

-

How to add needle positioner on adler 669

HarrySingh replied to HarrySingh's topic in Leather Sewing Machines

@shoepatcher @kgg Do i needle to drill hole and thread with tap for screw to hold it or just it has tight fit , please advise.... -

How to assemble 96k sewing machine thumb screw

depodarcom replied to depodarcom's topic in Leather Sewing Machines

I bought this machine 2 weeks ago. I havent used before. Stitch lenght dialer was stuck at first. I remove it and all the story started. 😢 I have lots of reserse mechanism machine but none of them resembles this.(Brother Ls2b837-DA669-Singer 196k5).Even the most similar one is 196K5 but when I press reserse in 196K5 it bounce but this has nothing. Also by turning the stitch disc, reverse lever should go up or down but this is motionless. Since its weight, I dont want to move the service May be I should try to change assembling order of parts. -

Hi! I recent got a Astor hand press, the A51, classic grey etc etc And know I want to stock my arsenal with tools and attachments for this fantastic machines. So I bought what I thought was a genuine Astor tool-adapter-thing that I needed for a lot of my old attachments. ***All of this text end my questions is about the upper threads on the machine*** And the tool didn't really fit, you know it that way when the threads are not 100% in the feel when you screw it in the first time. Back and forth for a couple of days, with the official Astor seller in Sweden, and we couldnt figure out what was wrong. So I took the situation in my own hands and started to dig! After a couple of years with working on sewing machines from all over the world and my true passion motorcycles, Harleys, Euros, Japanese doesn't matter, I have had my struggles with bolts and threads before. I have more tools, screws and bolts than the average middle age man, but I don't have everything... apparently... I can't figure out the true size of the "thread system", if you like. And I didn't have any right bolts that fitted exactly correct so I couldn't use the classic thread gauge tool. Searching the internet didn't really got my any answers that pleased me. Even emailing the company to get hints of; this is a secret...hmmmm!? They didn't want to answer any of my questions haha, I couldnt believe it! Is this true?! Is this an international secret to know what thread sizes Astor uses on their machines?! Will I get "taken out" if I continue? Jokes aside, someone? Please help! It's the Classic grey A51 button press, and a vintage model 5 press (in excellent condition I might say) that I want help to figure out the threads on. I can't seem to solve it by my self, so it's time to ask for help I am losing my mind.... where is my mind... Attaching pics on my two beauties

-

Aaron! Sorry for replaying this late! But yes I found everything I was looking for, thanks man!

- Yesterday

-

If you're only going to be sewing things occasionally then hand stitching might be the way to go but if you definitely want a machine then don't mess around and look for a walking foot, DO NOT buy a domestic machine and expect it to sew leather (regardless if someone says it's a "heavy duty/semi-industrial" machine). The deciding factor is the total thickness you want to sew.

-

Black powder double shot snake need help

dikman replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

As they say, the customer is always right. I guess he knows what he's doing, regardless you did an excellent job on the snake.