All Activity

- Past hour

-

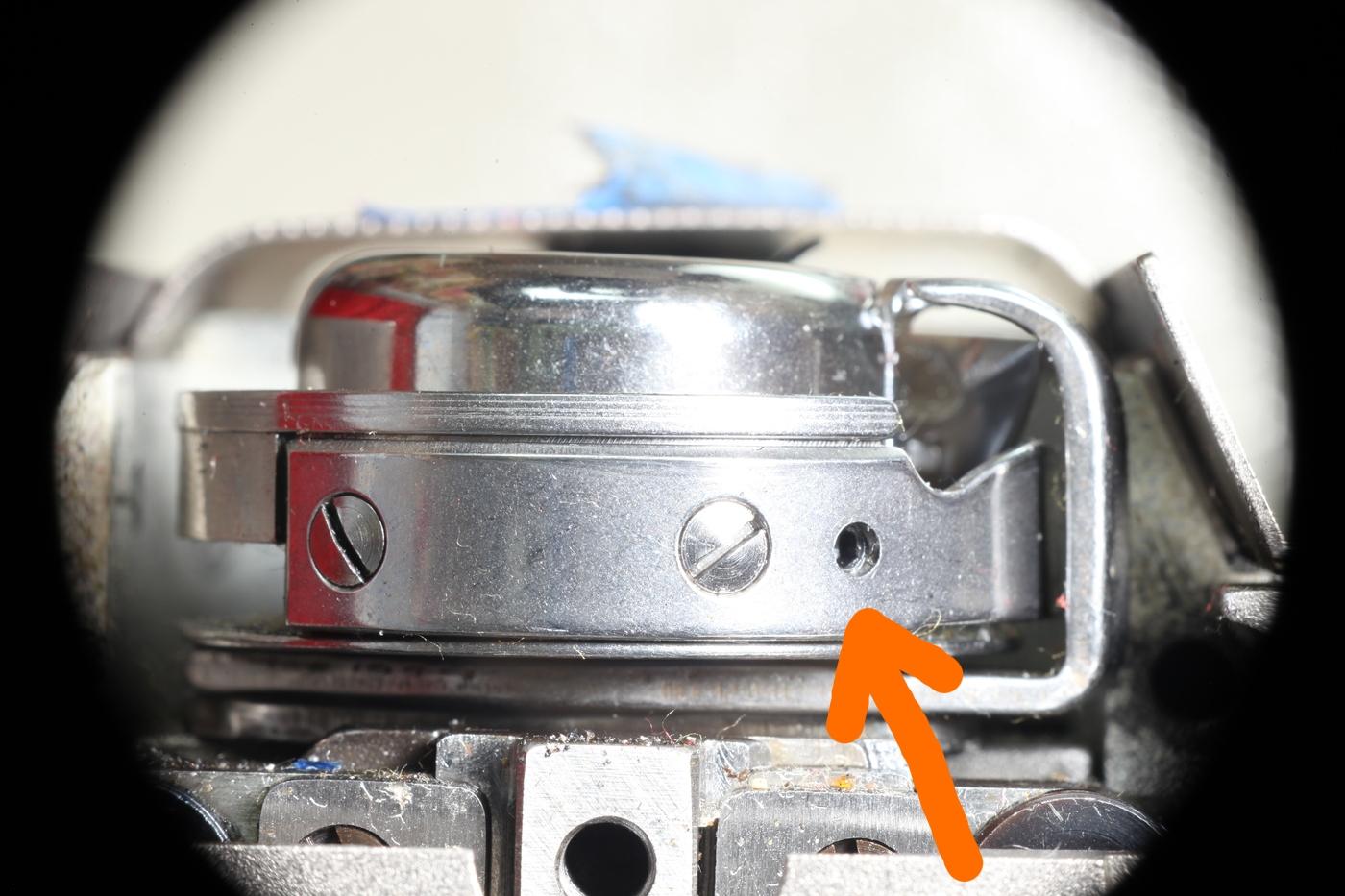

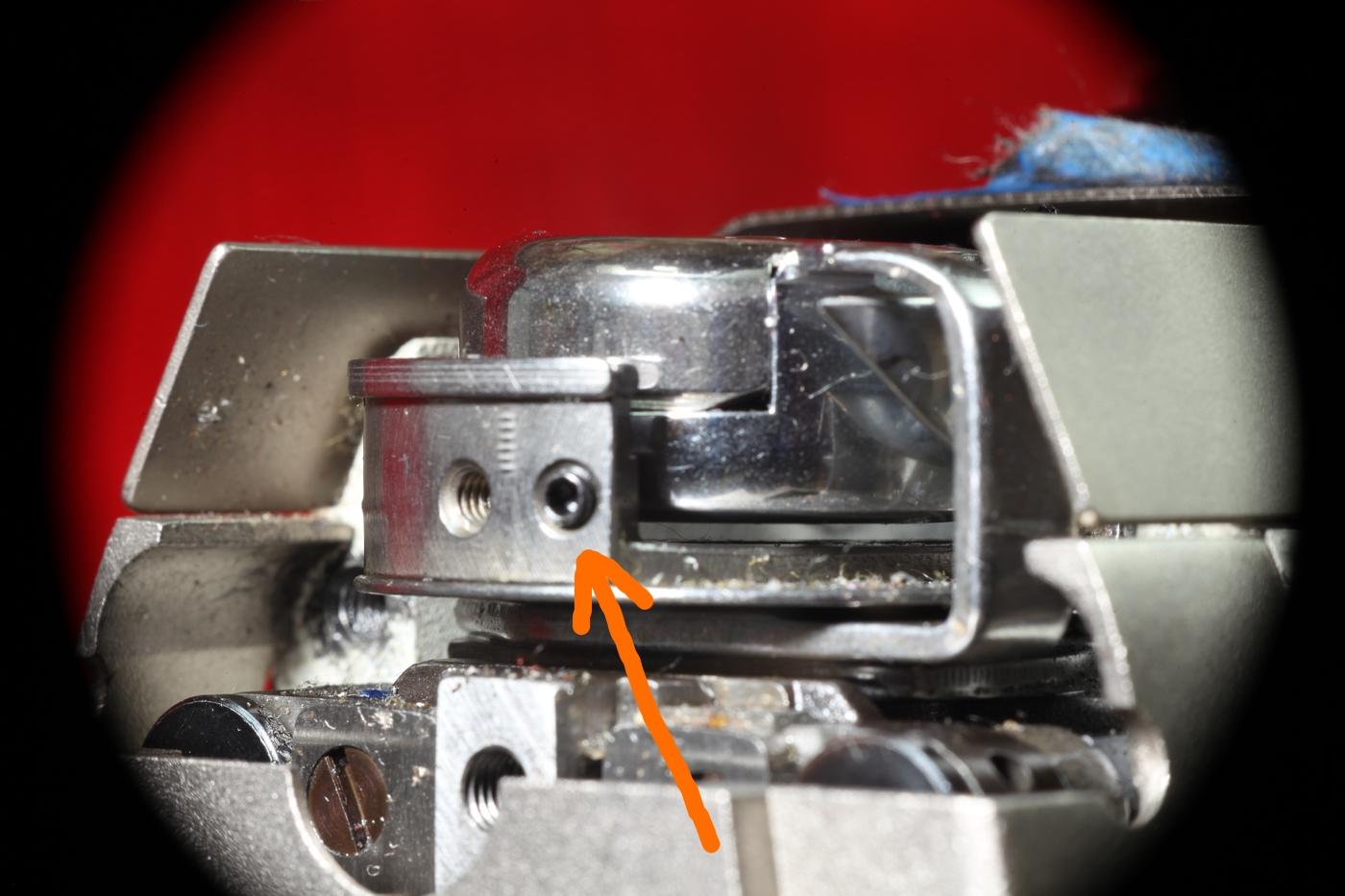

I hadn't noticed this before, but I think it's an adjustment screw for the needle guard. (Jianglong 341) Looking closely, I could see a hexagonal shape behind the round hole. 1/16" (1.7mm) hex wrench seems to fit. Or from a different angle: Here I removed the needle guard and you can see the set screw that sits behind it: I've been wanting the needle guard to be stiffer anyway. (What good is a needle guard that just gets out of the way when the needle comes by?) Using this adjustment screw will mean there is a support closer to the bulge in the needle guard, so I expect it to flex less when the needle presses against it.

- Today

-

That looks really nice. I like harness leather bridles. Randy

-

Thanks for the compliments. The young man can play, so I hope the strap can keep up. He's getting really popular thanks to TikTok. I don't understand, but I guess I'm too old. I think the font appearance is an optical illusion since the strap is curved over a post. The letter height is within 1/16" but the width may vary. If they are tapered, it certainly wasn't intended. Randy

-

I just answered your email and came here to see this. I can expand a bit on what I didn't cover in my reply there. Straight edgers - generally flat bottom and cut a flat profile. I mostly sell them to makers of English horse tack. Round edgers - several styles that cut a rounded profile, concave bottom surface, some have a convex shape to the top edge and some are flat on top. usually a longer life with they are a blade style edger and easiest to maintain. My favorites. Cowboy edgers? - may be referring to Western edgers aka bent-toe edger - fairly easy to maintain, curved profile from the side. As they sharpen back the cutting edge goes back further and further around that corner and the angle you hold them at lowers. Bisonette edgers - hole in a flat blade and can theoretically cut on a push or pull stroke. How often do most people need to pull? Pretty rare. Harder to maintain and sharpen without widening the cutting edge. My wife likes them a lot. I sort of do but never saw any huge advantage. Finest edger, fine edger, Gomph Common edger - these have a V shaped fork in the tip. rounded profile, fairly easy to maintain, can trim linings close to a stitch line, sharp tips and are sometimes called "finger stabber edgers". Common edgers - lots of versions and several edgers get lumped as common edgers. Some of the vintage unmarked ones from Osborne were referred to as common edgers. rounded profile, easy to maintain, easy to widen out sharpening unless you are careful. Gomph called their "fine edgers" as "common edgers". French edgers - flat profile, can be used for edging, skiving edges, and if they have the right profile will gouge channels too. You asked in your email about tight inside curves - the turnback edgers will do that - short lifespan and tricky to sharpen. A round edger with short toes and narrow sides will do inside curves too.

-

Just seen this on YouTube.

-

@Curious Observer If making bags will be your specialty, start making plans to obtain the industrial sewing machines that are best suited to that work. Number one would be a cylinder arm walking foot machine. It should have at least 10.5 inches clearance to the right of the needle. With this type of machine you can sew completely around a bag from the outside. This is great for installing zippers as a last step. You can even use it to hem pants! Number two might be a post bed machine with a roller foot. If the post is tall enough, you can use it to sew along the bottom of a bag. This machine is also great for assembling hats, or sewing patches onto hats. Number three could be what we call a "patcher," which is a cylinder arm machine with a foot that rotates in 360 degrees that pulls the work in any direction. While the bobbins are small compared to standard industrial sewing machines, their narrow noses can sew deep into areas that other machines can't access. You're already working on getting a flat bed walking foot machine. It will handle sewing seams that lie flat.

-

That's a beauty! What caught my eye immediately is the way the vine is woven around the flowers to create a criss-cross appearance, and how you decreased the size of the letters to complement the shape of the point. Lots of neat details. Thanks for sharing.

-

Excellent work! I hope their guitar playing keeps up with it

-

I agree with Tom, first thing is to get your knife razor sharp! Then adjust the feed wheel and presser foot to suite.

-

This is a clone that is the predominant skiver available today. The Chinese pump them outta a factory or two. Mine is a Chinese clone branded "Techsew". They may all need more, less or nothing to get up and running.

-

I finished the side pull last night. I ended up using Herman Oak harness leather and hand stitched it with Maine thread. It was a little more involved project than I thought it would be, could be because it was the first time I’ve made something like this. The nose band took a couple of tries to got right. In the end I think it turned out pretty good. Let me know what you guys think about it. Thanks.

-

Hi to everyone. I'm a noobie to this forum and a beginner leather worker. In the past, I fabricated some axe and hatchet masks as well as some knife sheaths. For the sewing"holes' I first stamped some holes with a 4 mm Craftool then drilled these out with a 5/64 bit in a drill press. I saddle stitched the pieces together with Tandy Harness Needles size 000 and some thick waxed thread of a size I no longer know. I would now like to fabricate some belts for friends and family. I've spent hours researching needle size and pricking irons and am now more confused than ever. Some (much?) of this confusion is due to the limited number of suppliers up here in western Canada. Can someone steer me in the right direction and provide me the correct needle size and 'hole maker' I need to sew with .8 mm Ritza thread. If you can recommend a source here in Canada that would be a bonus. Bobby B

-

Can any one explain the different types of edgers? I have seen the following straight edgers round edgers cowboy edgers bisonet edgers common edgers French edgers I need an edger that will work with 7/8 and 6/7 that will cut tight curves and make my edges round. any advice ?

-

TS custom leather joined the community

-

Heck yeah, nice work!!!!

-

Let's see the blade and how you hold the tool. Why do you put it in the fridge? It will stay too wet All you have to do is mist your work, then put some plastic wrap over it and seal it up. You don't have to rewet it to the point of soaking it, nor keep it that wet when not working. The idea is that you get it moist and keep it moist enough to work when you want to work it, not supposed to be a process of overwatering then waiting hours for it to dry every time you want to work. PS, it takes years to learn to tool well. youre doing fine. Merry Christmas!!!

-

A local industrial sewing machine guy is a valuable asset. The 280-L appears to be one of the many machines like the 111W series and it should have reverse. Most of us equip a machine like that with a servo motor and a speed reducer. But that's a rabbit hole you can burrow into if you decide to pursue it.

-

Inadequate knife sharpness, or too much moisture. Ugly "drag line"

AlZilla replied to LakeOtter's topic in How Do I Do That?

It's a good question and I'll be interested in what the mad geniuses here have to say. Does it happen before or after you refrigerate it? Or does it matter? -

1925 Harley JD Seat Restoration

Mulesaw replied to Irishleather's topic in Motorcycles and Biker Gear

@Irishleather It looks really good! A seat is a difficult project due to all the curves and swooping shapes, so I think he did ha great job. I think the colour is spot on. It will be a joy to ride once the entire motorcycle is completed. Brgds and merry Christmas Jonas -

Domestic sewing machines

Curious Observer replied to Curious Observer's topic in Leather Sewing Machines

HaHa, did you see that? Like I said, we both limped after it was all done. Many adventures on that first attempt at a bag, or pretty much anything for that matter. That little project pushed both the machine and I beyond our capabilities but we survived! I'm just shameless enough to show it on this forum. -

After reading that, I must admit that my hands have toughened up over the years, pulling on thread isn't so difficult , but these days it's arthritis, carvers cramp, and my left hand seizes up holding a stamping tool,can be painful at times. I like dikmans idea though. HS

-

Price drop; £650