All Activity

- Today

-

Those are nice. I may have to save up for those. I have an awl also but I'm really not big on round holes. I also have a stitching wheel that I got a while back. I need to get that out and practice with it also. Thanks for the response!

-

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

Glad to hear it! I'll pour one this afternoon, and toast your (and your daughters) success -

We'll call those "Hinges" most of the time. On the plus side, that style only comes in ones size that I'm aware of, so if you find some that is the right shape then they should fit. There are other shapes out there as many manufacturers came up with their own design, but that one is pretty common. Depending on who you get it from, some will come with the metal part that fits into the hole in the back of the head, and some they are sold separately. The metal part you have is one someone made, as the original is made from flat steel rolled into shape and Nickle plated.

-

AlZilla started following Western Apparel

-

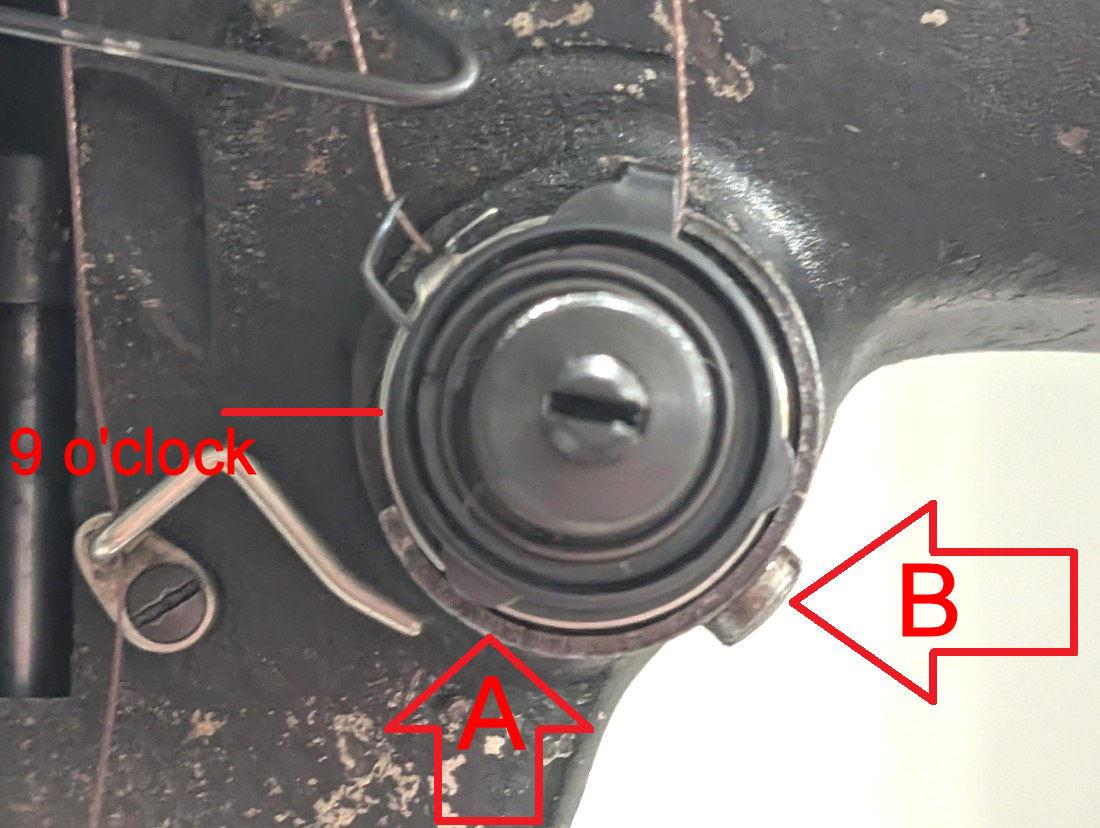

The check spring should rest in ~ the 9 o'clock position. There is a curved metal piece (A) underneath the tension unit that is secured by a screw (B). The end where the check spring rests on should be at approx 9 o'clock and the check spring needs a little pretension so when the thread lever goes down the spring goes back on the rest.

-

I use an overstitch wheel or these pricking irons to mark holes https://www.rmleathersupply.com/products/rocky-mountain-premium-pricking-irons. I make the holes with Osborne sewing awls of various sizes. A sharp awl works well for thick leather, irregular shapes, and sewing under fixed loops/keepers. The awls get smaller as they are repeatedly sharpened, so I can match a range of thread sizes.

-

Elrus4 joined the community

-

Yep, then the thread would be behind that finger pointing upwards at 11:00. When everything is working right, you'd pull the thread around the disk and them pull it up until it snaps behind the finger. Most threading videos for machines with an exposed tension unit will demonstrate it. On the other side, where the thread enters the tension unit, it ought to be straighter and more taut, but it may just be loosely strung around there in the pic. Making headway. EDIT: Right at about 2 minutes of this video, Randy Your Sewing Machine Man demonstrates it nicely:

-

Western Apparel joined the community

-

-

I can get you started. See that round spring pointing straight up on your tension unit? Right at the 12:00 position? It should probably be at about 10:00, straddling the thread. There's some other odd stuff there I won't comment on, but the check spring gets you started. Edit: I think I see a set screw on the side at 5:00. Should be that if you loosen it, you can rotate the check spring into position.

-

GoldenKnight started following BlackDragon

-

Interesting. I thought I installed it correctly but I'll be the first to admit that I don't know that much about these machines. When you have time let me know how it should be. Thank you.

-

I’m happy to report that the inventory has found a new owner and is in good hands. Thanks to all who had expressed interest! Cheers, Uwe

-

The black body Cowboy machines were a special custom color made for or by a Texas based dealer, who has been out of business for several years now.

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Screws ripped out of saddle tree

Northmount replied to Mendosa's topic in Saddle Identification, Restoration & Repair

There is a big difference in holding power when you compare screws run into end grain versus screws run across the grain. The screws that are run into end grain easily shear and pull out. Compare to chopping with the grain (splitting wood) versus chopping across the grain. Anyone that has chopped wood knows the difference. I've had screws in end grain pull right out where they didn't when screwed into cross grain. -

rktaylor started following Screws ripped out of saddle tree

-

Screws ripped out of saddle tree

rktaylor replied to Mendosa's topic in Saddle Identification, Restoration & Repair

At some point I'm going to start worrying about the bar. Once you drill and patch enough holes, there's not going to be much original wood. You could patch the holes with dowel as suggested, then drill new holes also as suggested. Pictures would help. Randy -

laleyendabizzness started following Cowboy CB4500 or Cobra Class 4?

-

Cowboy CB4500 or Cobra Class 4?

laleyendabizzness replied to AngryDick's topic in Leather Sewing Machines

Do you happen to, or anyone else, know if this same setup color and all is still an option? I've looked everywhere online and can't find it.. Blessings, JB -

Screws ripped out of saddle tree

Tastech replied to Mendosa's topic in Saddle Identification, Restoration & Repair

I would use a wooden dowel to repair the hole and then fix the screws into the same position. Select a dowel size .eg 1/4 " dowel . Drill out the existing hole with a 1/4' drill bit . Apply a high strength wood glue and knock in the dowels . When dry after 24 hours screw into original position . It's pretty much the same method a carpenter would use when replacing screws on the hinges to re-hang a loose door . The method seems to work well . - Yesterday

-

Quentin C joined the community

-

Screws ripped out of saddle tree

bruce johnson replied to Mendosa's topic in Saddle Identification, Restoration & Repair

Call your saddle maker and tell them what happened. My guess is that at a minimum you will be told to move the screws and not use the same holes. -

Screws ripped out of saddle tree

Hildebrand replied to Mendosa's topic in Saddle Identification, Restoration & Repair

I have never done any saddle work but could you countersink a tee nut from the other side and use a machine screw? Todd -

Mendosa joined the community

-

I have a bronc saddle that has ripped the screws out of tree from the riggin on the right side, as a quick patch on the road we cleaned the holes out, patched it with JB weld and sanded it back flat, this held for about 12 horses and now has ripped back out, does anyone know of a better method to fill holes in a tree?

-

Lol Ya, I have a couple belt blanks that I've been wanting to carve. I like the way stitching on edges of a belt look but, no way am I gonna hand stitch a belt. I would probably have to have 20' of thread laying all over to stitch it. Lol Thanks for your replies my friend! Bobby

-

When I was hand stitching I mostly stayed with one size but depending on the item you may want to go bigger or smaller. If you're doing a wallet you may want a nice tight stitch but if your making a belt you may want to use a wider chisel. Stitching belts by hand can hurt your hands after awhile so using a wider chisel can lessen the amount of hole you have to stitch.