All Activity

- Past hour

-

That’s a nice looking bandolier!

- Today

-

Long Arm Highlead GC20698-2 for sale. Asking $3500 It's been in storage for awhile, but was lightly used. Machine is located in Metro Detroit, MI. I'm willing to crate for a fee, though pickup would be easiest. I also have a Fortuna skiver for sale. I would be willing to do a package deal for both items. Thanks! Matt

-

Communityoldman joined the community

-

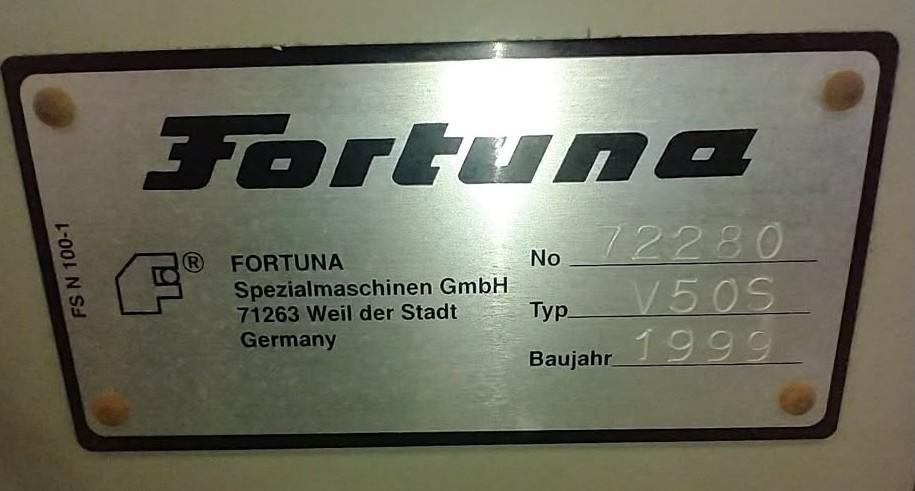

Fortuna Skiver Model V50S for sale. Asking $1500 It's been in storage for awhile, but was pulled in working order. Machine is located in Metro Detroit, MI. I'm willing to crate for a fee, though pickup would be easiest. I also have a long arm twin needle sewing machine for sale. I would be willing to do a package deal for both items. Thanks! Matt

-

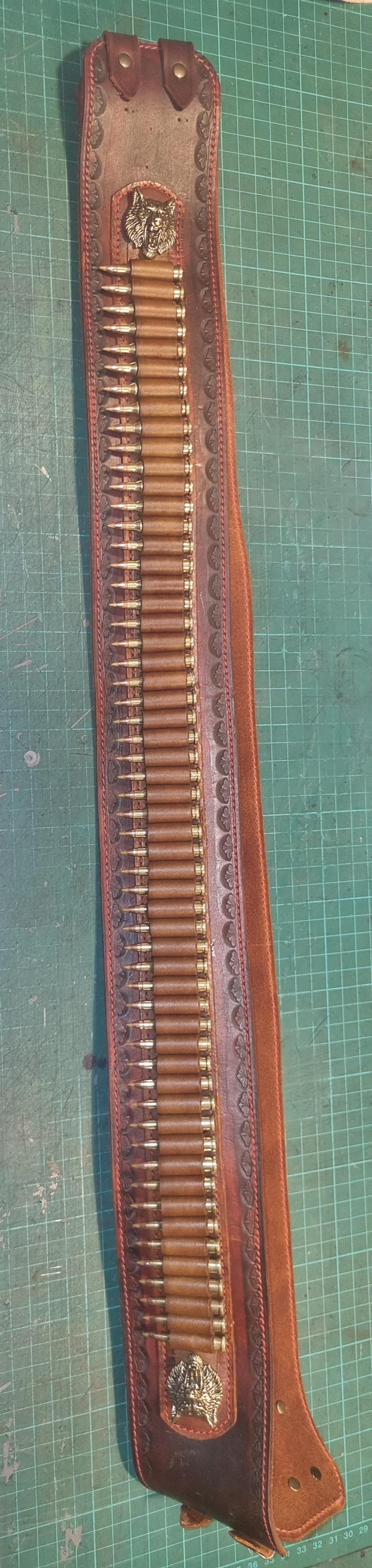

Almost finished. Far more work than I'd bargained for and my hands didn't thank for making the loops a bit tight. Quite happy with the result though. I haven't seen any for sale that include cartridges and these are ballistic tipped, our laws over hre are pretty strict even on components for making so I had to make sure they definitely couldn't be re used.

-

Thanks, I'll check that out. WOW......that's 160 miles from Arthur!! A bit of a stretch for his horses! Are you a highpower shooter?

-

I'd say so. Years ago I read John Bianchi's book on holsters (1980's). In it he detailed a bit that they would treat molded and dried holsters with neatsfoot oil, then place in the California sun for that rich golden glow and then treat with hard wax. Resolene would have pretty much the same effect as using hard wax/mop and glo, etc. Bianchi was without doubt the expert on the subject. If such a thing worked for him, it will work for you. Just don't saturate the leather with Neatsfoot. I personally don't like Resolene. Your results may vary, so if it works for you, use it. I'd suggest Weaver tough Kote (or Tough Kote in BLACK) over resolene. It's similar, but slightly more matte than bright glossy. (Ok, may or may not be available in the EU?) I've used lots of Feibings Pro Dye (Oil Dye) and I never really had any stiffening or drying out to speak of. The cheaper Feibings dye is far worse for drying out your leather though. Are you sure you're not using it instead?

-

I received the 3 sets I ordered today. The L & R and needle feet fit fine but there is a difference in design and finish between the L & R but should work as intended. The "both" foot needed a touch with a Dremel stone to open up the width of the fork by the screw hole to allow the screw to pass through the hole, about 0.1mm. I've had this with some other feet sets in the past so no surprise.

-

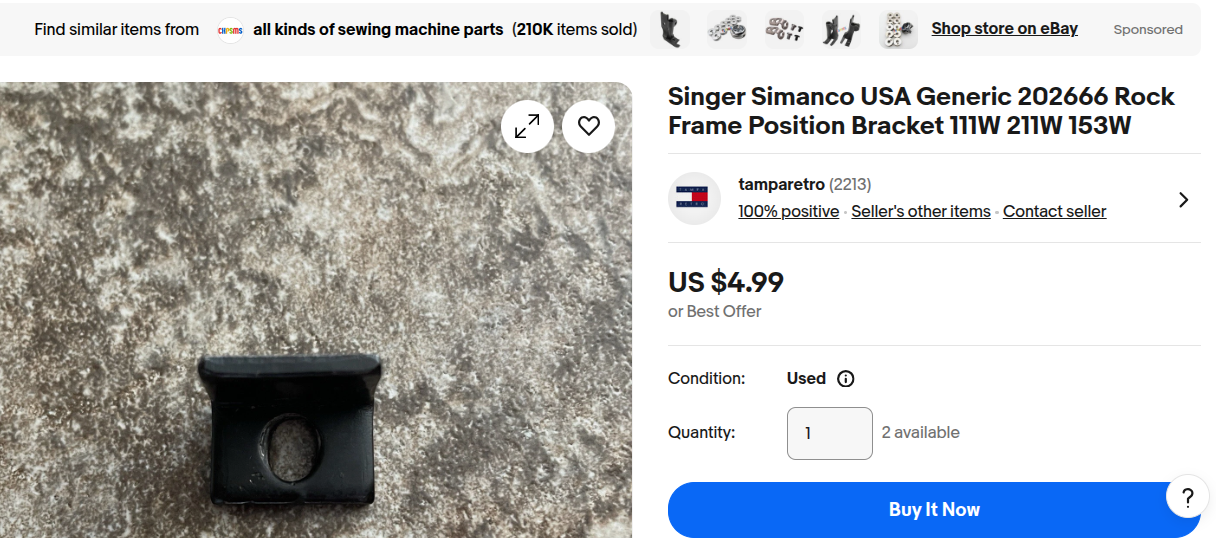

I did watch the video. I had to go look at my 153. I found the clamp in the attached pic that looks like it would affect the position of the needle bar. Haven't a clue. Yet. EDIT: The part number is Simanco 202666 and comes back as "Rock Frame Position Bracket". Do we have a winner?

-

butchmutt joined the community

-

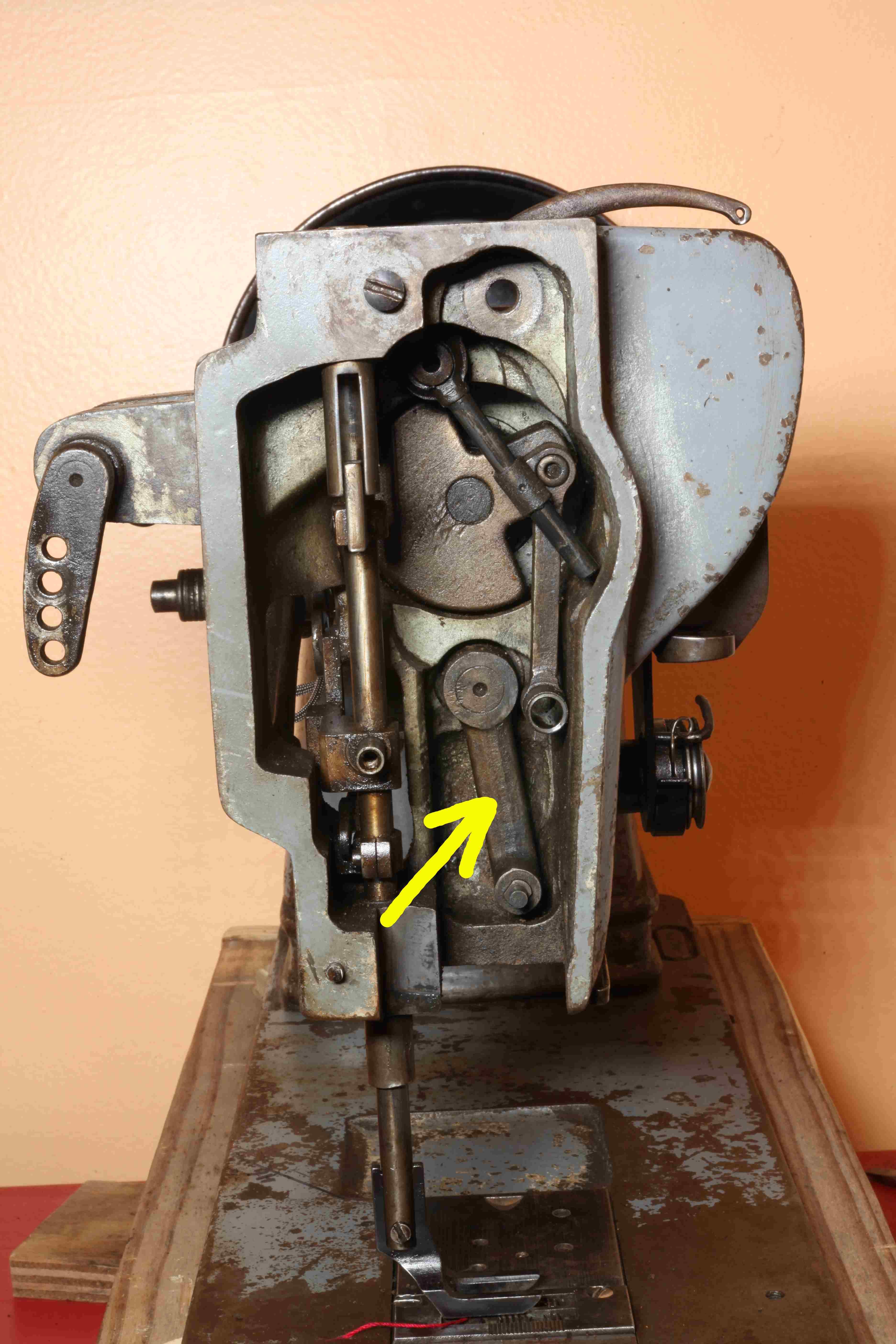

Is the handwheel easy to turn? Have you oiled the machine? (Do add some oil if not) Does the needle bar move front to back if you push it with your hands? You will need to find the clamp that Wyowally references and verify that it is indeed moving the "needle bar rock frame rock shaft" as singer calls it. We are looking for the clamp at the far right end of that shaft. If the clamp is loose, tighten it. Make sure the clamp and the rock shaft both move together when you turn the handwheel. If neither the shaft nor the clamp move when you turn the handwheel, flip the machine on its back and inspect the parts underneath that drive that clamp. If the shaft does move but still no movement at the needle bar, take the left end cover off the machine and find the crank arm at the left end of that shaft. Here's a photo of my singer 144W103 with the needle bar rock frame removed, and the yellow arrow points to the crank arm you want to check for movement.

- Yesterday

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Hand-sewing and zips. Bane of my existence!

Northmount replied to HondoMan's topic in Sewing Leather

Moved your post to Sewing Leather -

I moved your post to Marketplace Items For Sale Miscellaneous/Other

-

Replacement Pulley for Tapered Shaft

friquant replied to friquant's topic in Leather Sewing Machines

Can you post an amazon link? -

Thank you! I've removed covers and have attempted to find something out of the ordinary. Were you able to watch the video I posted about the issue? Looking forward to hearing what you find. Dan

-

I have a couple of this class machine but haven't run into this problem. Forgive me if you've done this, but it seems like popping that cover off and turning it by hand should yield some kind of clue. Just observing and following the mechanism back. I poked around a bit and couldn't find any videos on adjusting the needle bar position other than height. Tomorrow if it's warm in the craft room I'll look at mine and see if anything jumps out at me. Now I'm curious, too.

-

-

I think he moved? Two years ago I sent him a list of parts I wanted in writing to his long published Arthur IL address and I didnt hear back. A year ago I call his answering service and he called me back. Said he never received my order so I gave it to him then. When the parts came his invoice was overstamped McLeansboro. 6373 County Rd 400 N, McLeansboro, IL 62859.

-

FOR SALE - Cowboy CB12 Hydraulic Clicker Press - CLEAN - $2800

soulcraftgoods replied to soulcraftgoods's topic in Old/Sold

SOLD -

Thank you for the response! Much appreciated! This machine has been pretty much trouble free in my lifetime. Were you able to watch the video? I downloaded and printed the military manual and some illustrations were scrambled. Lubrication drying out? Does the needle bar get moved by a cam? Gets pushed on way and spring return? I'm attempting to wrap my head around how dried lubrication can cause the needle bar to act this way. Dan

-

Legacy Saddlery

MamiaGirl replied to MamiaGirl's topic in Saddle Identification, Restoration & Repair

Thank you so much.I still don't have any information on this saddle. But hopefully someone will know something.It's very well made. It's not too old.The leather is still very good and I use it. Does hoping to find some history on it. And what it sold for perhaps new. -

Kenzi joined the community

-

What tools helped enhance your leatherwork? Different types of knives, stamps, etc.? I am a intermediate leather worker, I believe that I still have lots of improvement to do and I am wondering what tools I can use to help me achieve this.

-

The seller of these has put a 55mm on amazon at my request. This is the only other size avail.

-

not sure what I would do with 50 yards of this webbing, but just on the historical part of the find, it's pretty cool. And olive drab. I haven't heard that color description in... well, since 19-longtimeago...LOL!

-

did you look here?https://fiebing.com/blog/

-

I also have the same machine, redone by me with help from others on this forum. I am not near it and won't be for a while. My first thought is the main pinch screw (the big-headed one) in the exposed linkage on the back let slip. Not common, but it does squeeze a clamp, so unwanted rotation is possible. Next thought is lubrication dried out if it has sat for years. Another possibility is something moved in the internal feed eccentric that also adjusts the two feet and their movement and relationships. I did find the military manual I have pretty useful. On YT, search for Uwe Grosse and his videos - not all specific to Singers, but also the other machines of nearly identical design. I found this very good.

-

✨ Help Wanted: Leather Tooling Artist ✨ looking for a skilled leatherworker to take on piece work for our busy, high-end tack company. We create everything from fantasy-inspired masterpieces to elegant western designs — and we’re looking for someone who can think outside the box, have fun, and bring bold creativity to the table. I will ship the pieces to you, so you can work anywhere you choose. Details: Paid per piece (rate based on complexity and quality) All leather and tooling materials provided (if needed). You’ll be creating parts for custom bridles, halters, breast collars, and more Must have a portfolio of previous work so we can ensure our styles align This is an excellent opportunity to collaborate with a well-established, high-demand equestrian brand with a strong following and reputation for unique designs Due to a recent hand injury, I’m no longer able to do the tooling myself, so I’m seeking a dependable artist to help continue creating the level of craftsmanship my customers expect. If you’re passionate about high-quality leatherwork and want to be part of something truly creative, message me with examples of your work and we can chat. Thanks! (I am located in CA, but can ship anywhere in the US)