All Activity

- Past hour

-

Damn I love you all and this community... Any kind of advice is good I really appreciate it . Seems like some people that are also starting are getting and providing some knowledge from this thread. For sure I will show you some of the work i make once I start. Thanks for the advice on the knife sheat I work in a kitchen so I think would be nice to make some sheats for my knives of even a knife roll (yeah ). Thank you all.

- Today

-

Very good advice. Making all your rookie mistakes on the first project.

-

When you say groove line are you meaning an indentation with something like a compass or an actual groover where you're taking off the top layer of the hide? If it's the first one I would do it as Bruce said. You may be able to undue the indent and it won't be noticeable. If it's the second I'd start over. I would keep that belt for myself or someone that doesn't mind a blemish but I wouldn't give that to a customer that's paying top dollar for a belt

-

Keep a straight stitch line and remember to watch the groover next time. I would rub out the errant groove line as best I could and regroove it before I stitch.

-

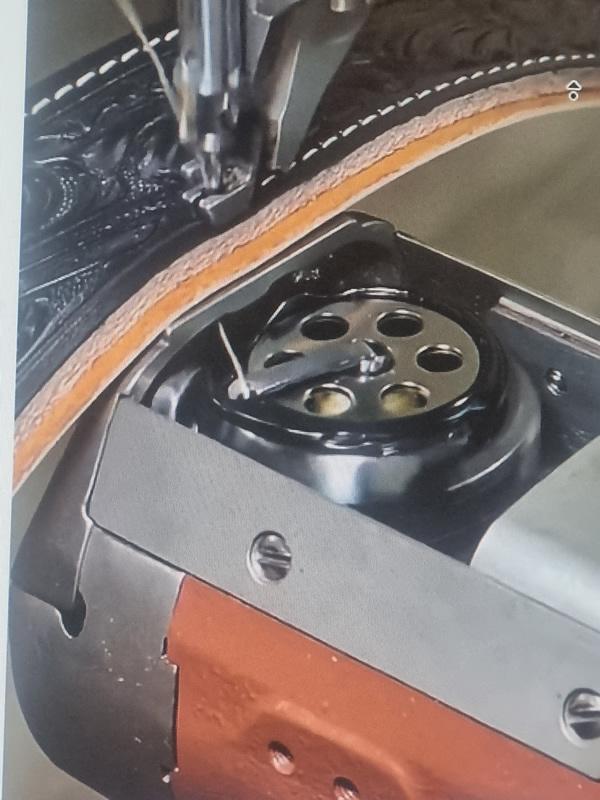

Saw this on a video short. Guessing it's a Cobra and noticed the thread going through the notch in the thingy that holds the bobbin in place. Is this standard because I don't see any way I could do that on my machine? Of course i could always be missing something.

-

Hey all, OK quick question… Let’s take a hypothetical here: Let’s say that we’re stitching something long and straight like a belt or purse strap, and our stitch groove has a wobble or so. Is it aesthetically better to keep a straight stitch line, or to follow the groove that isn’t necessarily straight? May you never burn your bacon, AZR

-

Hi all, I am looking to see if it's smart to upgrade from my Adler 167-373 to either a Juki 1541s or 1508n. My main use for the Adler is leather jackets and some Horween bag work using 5oz or less leather. I do run into some difficulties with the Adler for leather jackets that I had posted about years ago and the solutions didnt really make a difference, especially on the transition of slimmer seams to extra bulky seams. My Juki 8700 lockstitch can handle so much that I am looking to see experiences with either Juki above would be a huge improvement over the vintage Adler. Thank you.

-

I’m also very new to leather work also. All these tips are very good. I agree with buying a pattern and learning how to make it. Look for patterns on Etsy that have construction videos. I’’d suggest finishing the piece even if you mess up a stitch line or have a weird cut. There are several techniques that u learn from working a project from start to finish. I’ve messed up so much stuff but also have learned several skills along the way. I’d suggest getting a small card wallet pattern or something easy that u can build skills on.

-

Interesting information. Thanks for sharing.

-

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

when sewing boxing style mittens, the back is larger than the palm. To gather them evenly, they are handsewn with single stitches at first. One stitch at 12 o'clock, one at 4 o'clock, one at 8 o'clock. Then split the difference... so next at 2 and 10 o'clock, then continue single stitches at the biggest gaps. This makes the gathers even, but again, no machine works that way, except the human hands. -

often Ebay is a bit cheaper than Amazon - even from the same seller. Just saying...

-

My two cents worth: Notes i) The recommended size of needle for Tex135 (V138) is a 140 (#22) thin material, 160 (#23) medium material and 180 (#24) thick material. ii) Your 130 needle is really meant for Tex90 (V92). A good reference chart is ( https://www.tolindsewmach.com/thread-chart.html ). iii) V45 has a breaking strength of 7.5 lbs iv) V69 has a breaking strength of 11 lbs v) V92 has a breaking strength of 14.5 lbs vi) V138 has a breaking strength of 22 lbs If I'm not mistaken the 269 is cylinder arm and by adding a simple table top attachment you would have sorta kinda a flatbed for versatility. Personally I wouldn't bother changing the thread size and do all the sewing with Tex135 (V138). kgg

-

@AlZillaCorrect, not inexpensive at 120€, but if I try it out and it runs fine, I think I'll just go for it as I have neither the time nor the inclination to find a used machine from a private owner and try to get it back in shape.

-

Thank you for your replies. It gives me some assurance that they should be good.

-

Beautiful work. Your tooling is first rate and the two-tone really makes it.

-

I would like to second toxo's post. It's so much easier with a pattern. Well worth the $10. In addition he has instructional videos to go with the pattern. With these patterns you need the minimum in tools. Use a 1.5 mm punch and get some tiger thread, some needles and go at it. The stitching is alot easier this way. I wish I had figured this out earlier, it would have saved alot of frustration.

-

Thank you for the info! I really would like a 51w model and will keep searching online marketplaces, in hope of finding one.

-

Same ad as https://leatherworker.net/forum/topic/132423-new-adler-669-i-have-three-of-them-2500/#comment-788786 except for the price. We can edit the price for you instead of duplicating ads with a price change. Also this ad is located under used. Like new is a better location. Let me know what you want done with these so I can clean it up a bit instead of conflicting ads.

-

Welcome to LW. I moved your post to the Marketplace. Home > Marketplace > Items For Sale >Leather and Lace Please read the marketplace rules and conform. You must provide a price, condition of equipment, any information or restrictions on shipping, and photos when possible. Failure to conform may result in your ad being blocked. See the marketplace rules here https://leatherworker.net/forum/forum/70-announcements/ We need some pictures, price, shipping info or restrictions.

-

Steele Saddle Trees on Crates/Fabtron Saddles

bruce johnson replied to ellaecman's topic in Saddle Construction

The narrow bars just means that the bars are not as wide through the middle (waist) as other trees - theoretically for closer contact. We could get into a big discussion of whether that is true in real life, but that is another rabbit hole. The narrow bars should mean less contact surface and again - theoretically less weight bearing surface. The front and rear of the tree bear weight and the area overall is what controls pressure. A narrow waist on a tree is a minor factor fit. Bar angles, bar length, twist, rock in the bars, gullet/ handhole width, and relief at the bar edges are all bigger factors for fit than that narrow waist. -

I'll second CKPSMS. They're on amazon or ebay. I've purchased quite a bit and always been satisfied.

-

I have bought two edge guide presser feet for my Pfaff from CKPSMS through Amazon and am very satisfied. It can be hard to find parts that fit the older Pfaffs, these were just fine. Bobbins in my opinion can be bought anywhere and they should be good.

-

Took me a while to realise that hand sewing works around dissimilar curves because it draws the two halve together gradually. In some cases the stitch holes are different on each side to facilitate. The simplest way when they get too far apart is to go back now and then and use the previous hole twice to even up but doesn't look good if gonna be seen. When machining it's sometimes easier to "V" notch arounf the bends.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)