All Activity

- Today

-

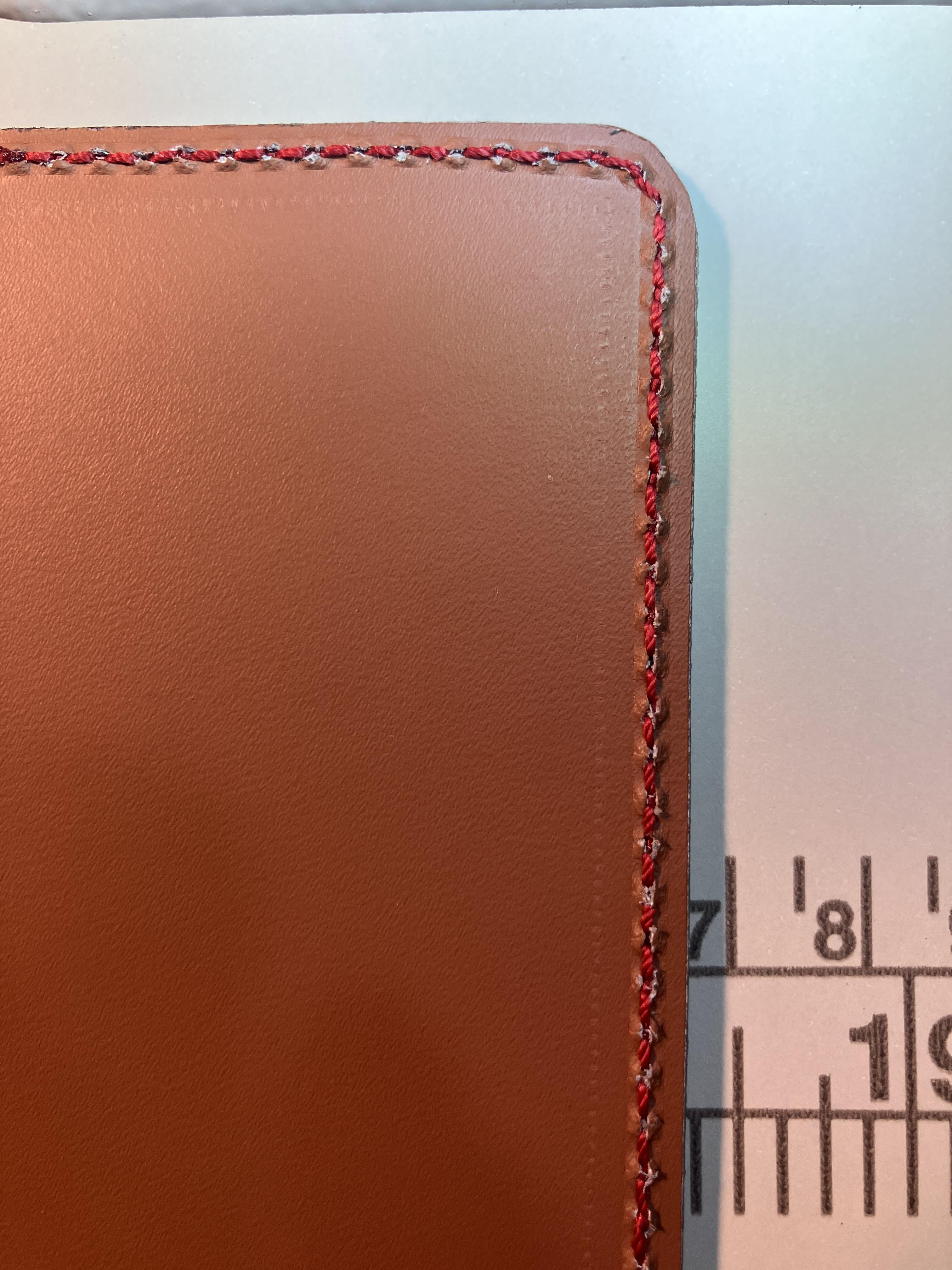

Micro Copper Burr Rivets - A Solution

Stagesmith replied to Stagesmith's topic in Hardware and Accessories

The 2.5mm and 3mm washers do clinch onto the rivet shaft just like Burr Rivets. The 2mm washers are just a tiny bit too large on the ID, so they don't clinch, but I didn't find that made it any harder to use. If you bop the washer sideways with a tiny hammer, it can distort the hole enough so it does grab the rivet shaft. -

Vilh. Pedersen 282 clicker press manual

RockyAussie replied to RockyAussie's topic in Leather Machinery

Does anybody have one of these that could advise me what grade of oil it should use? -

Can sewing marks be eliminated?

Cumberland Highpower replied to ozleather's topic in Leather Sewing Machines

Might be some plates/feet/dogs that are smooth for that machine? There's a guy in Japan that makes wallets among other things and he uses Seikos with large knurled presser wheels. Wheel marks everywhere, but that's part of his trademark look. Just saying if you can't beat'em, maybe join'em? -

135x16 apparently the same as 135x17 TRI

Cumberland Highpower replied to AlZilla's topic in Leather Sewing Machines

I've used some Organ needles and they seemed to be overall a good needle. Schmetz are better overall but it is what it is. I've also bought them for hook and awl machines and in that regard they are just as good as any other. -

Try going over the stitches with a polished leather hammer. Or a polished bone folder.

-

Problem using a TandyPro Deluxe Leather Splitter

DieselTech replied to Coloradoguy's topic in How Do I Do That?

@Coloradoguy I recommend buying a second blade for your splitter, then you got a blade that can be sent out to be sharpened & you won't be without a splitter blade while 1 is being sharpened. -

135x16 apparently the same as 135x17 TRI

AlZilla replied to AlZilla's topic in Leather Sewing Machines

Probably because that's what I could find in the sizes I wanted. I've never had any problems I've blamed on a poor quality needle. My complaint is why label them with confusing, made up designations? -

Problem using a TandyPro Deluxe Leather Splitter

Coloradoguy replied to Coloradoguy's topic in How Do I Do That?

Thanks Jonas, I do know of that company in Omaha. Thanks Tom, I'll be reaching out to Bruce. -

- Yesterday

-

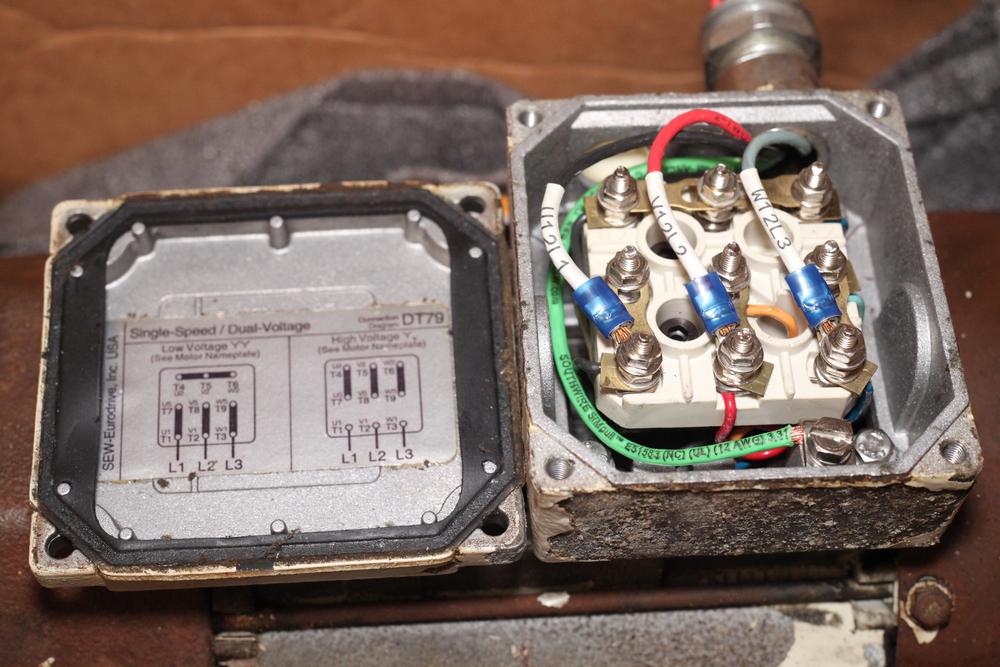

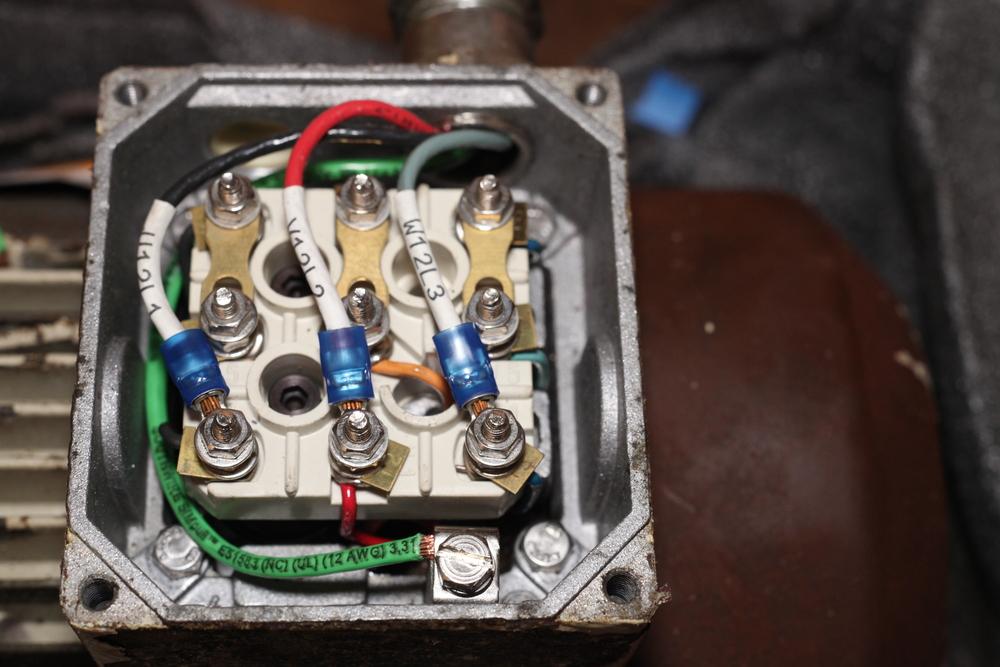

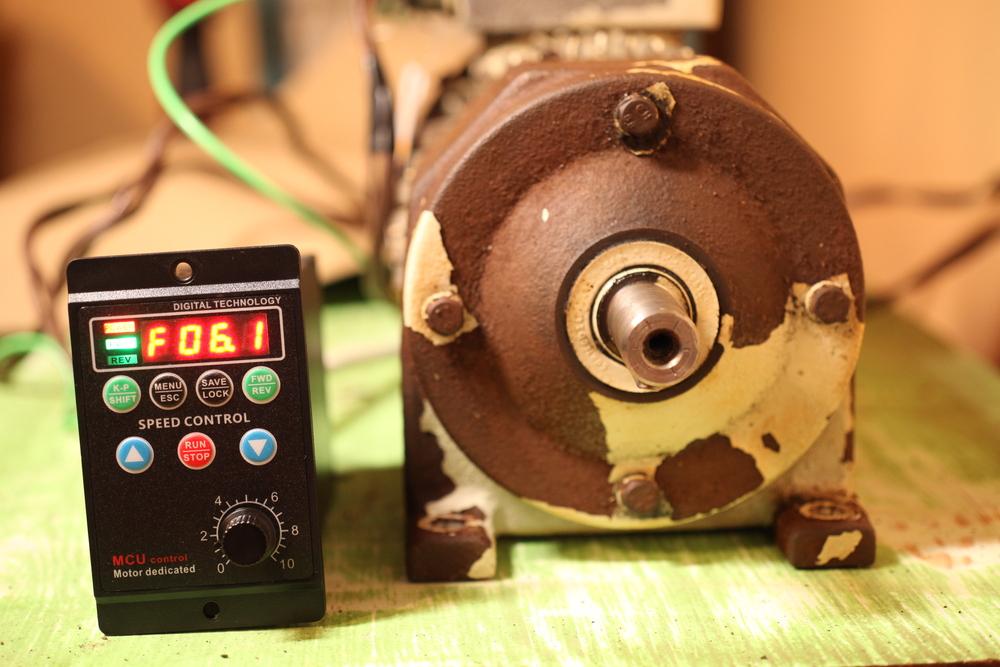

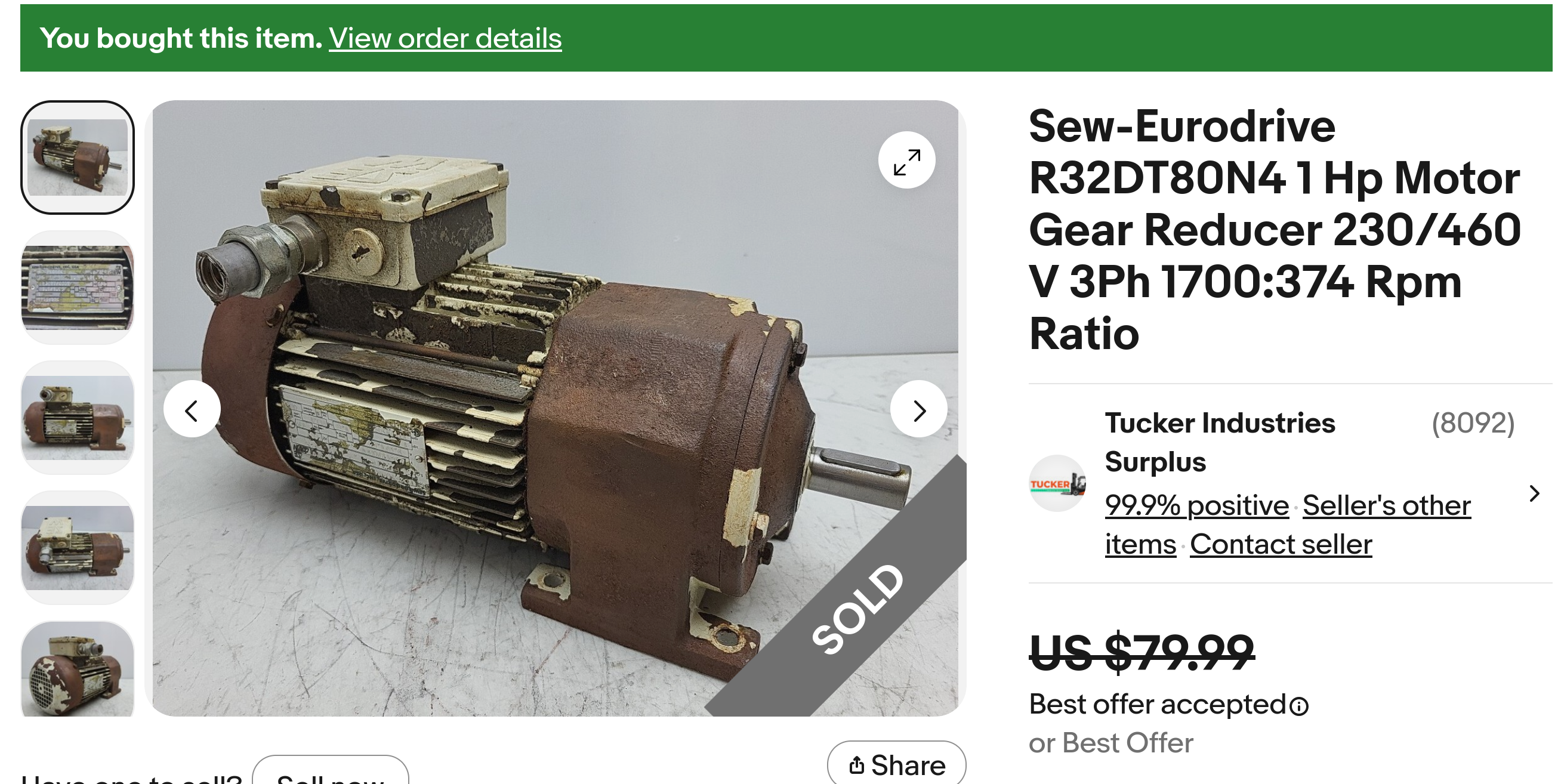

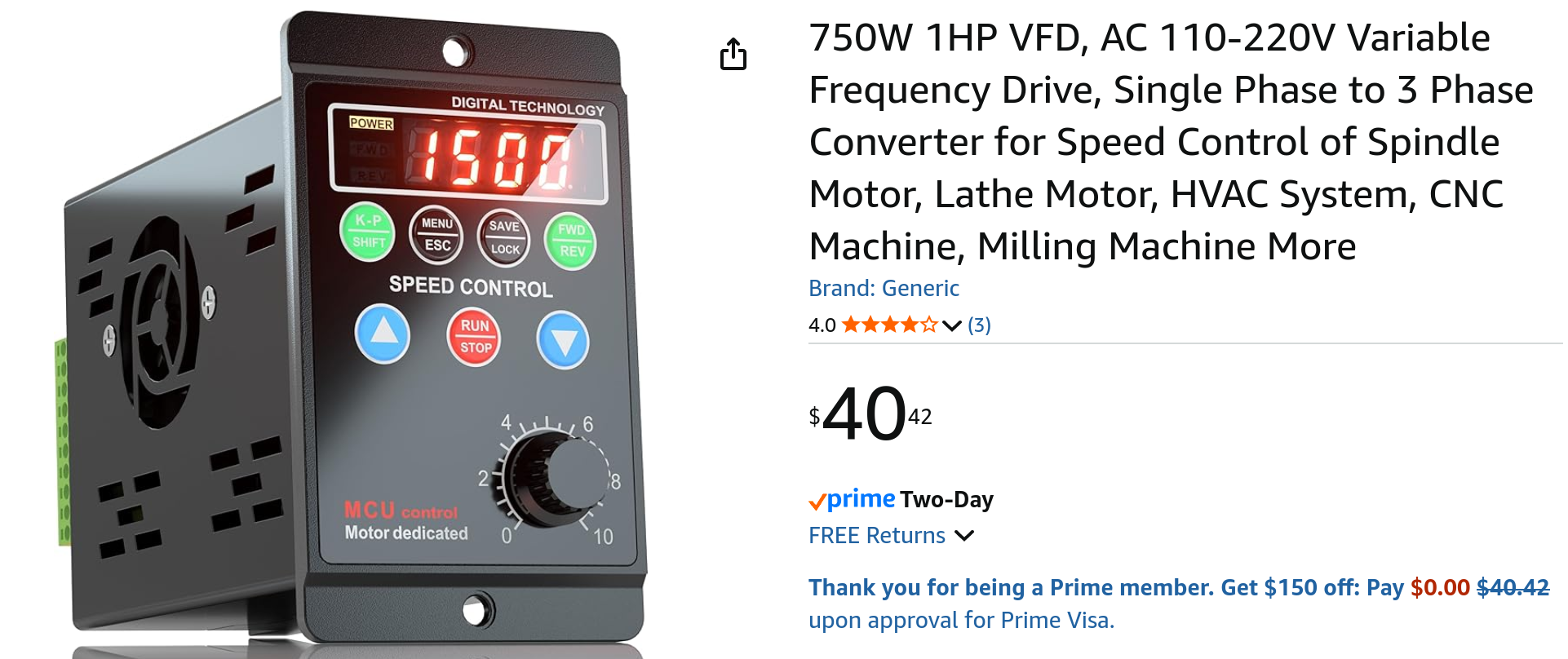

Today I was able to bench test my first 3-phase AC gearmotor running on VFD. It's a foot-mounted Sew-Eurodrive 1-horsepower with 4.5:1 gear ratio. Gearmotor A four-pole AC motor typically has a speed around 1500 rpm when fed 60Hz power from the wall. With the 4.5:1 gear reduction, that puts us around 330rpm with wall power (60Hz). So long as the AC motor is 3-phase, we can add a VFD in the mix to control the frequency of the power going to the motor. And voilà, we have a motor that can go anywhere from 0rpm up to 330rpm. At least that's the theory I've been reading for the past few weeks...I hadn't seen any of this in action until today. This ragamuffin came to me by way of ebay. Here is the original listing. I'll include a screenshot of the listing because these listings go away eventually. This motor is bigger than I needed. 400 watts (1/2 horsepower) or maybe even 100 Watts (1/8 horsepower) would suffice. But this one I found for a song, only $65 after shipping. I did verify that it was actually 3-Phase before buying. (See the "3PH" in the upper right corner of the motor nameplate) The box arrived a few days later. It was packed cozily in cardboard and foam. The outside of the motor is gritty. Perhaps it's been running in a moist environment. The ad says it was taken from a running system. I'd like to clean it up and paint it, but I want to see it run first.. The wiring was set up for 380V, so I reconfigured according to the diagram for the 220V that my VFD will output. (My VFD takes 110V single phase as input, and outputs 3-phase in the range of 220V.) Here is before and after, note the copper strips have been repositioned under the nuts to effect the wiring change. VFD The VFD (variable frequency drive) I've actually had for a couple weeks while I've been looking for motors. But I've never owned any 3-phase equipment so had no way to really test the VFD, hence the excitement when the gritty box finally arrived. 🤪 Here is a link to the VFD I'm using: https://www.amazon.com/dp/B0D53Z7RZ5 And a screenshot: Here's what the back of the VFD looks like. The two red "AC" labels are for neutral and 110V single phase input. FG is ground, connecting both to ground in the wall outlet and to the ground on the motor. The blue U, V, W are the 3-phase outputs which the VFD can control to be any frequency from 0Hz up to I think 100Hz, which is how the VFD accomplishes speed control on an AC motor which would otherwise be fixed speed. The green strip on the right is for low voltage input/output. One of them can be used with an external potentiometer to set the frequency. I've ordered a TIG pedal for this but it has not arrived yet---So today we'll use the built-in potentiometer/knob on the front of the VFD to control our speed. Bench Test Here we are on the bench: And a video gearmotor-voice-01.mp4 Many thanks to @GerryR who has fielded a LOT of questions from me as I've been pursuing this journey.

-

Problem using a TandyPro Deluxe Leather Splitter

bruce johnson replied to Coloradoguy's topic in How Do I Do That?

Thanks Tom, I do sharpen splitter blades. I am currently in Ohio at a leather and tool auction. I will be back in the shop middle of next week -

Why not just cut to the chase and buy a better brand of needle like Schmetz or Groz-Beckert needles??? Personally I have tried most brands and can honestly say that Schmetz needles have never given me any problems in any of my machines. I would say the Organ needles are a more budget-friendly alternative and cost about 50 percent that of Schmetz needles with Groz-Beckert somewhere in between. kgg

-

135x16 apparently the same as 135x17 TRI

AlZilla replied to AlZilla's topic in Leather Sewing Machines

This is how they're listing them. Seems a company like Organ would know better. On the other hand I suppose I can see lazy people calling them "135x17 leather points" and just expecting the great oracle to figure out what they mean. -

charleneanswers joined the community

-

You are forgetting breakage due to abrasion on the thread. In my history group I had experience of that. The chaps used to do several very active live steel fight displays during a day. I had shoes to resew/repair. The stitching holding the soles to the vamp often got abraded until they broke. On those made by one 'expert' and hand sewn using saddle stitch the sole came loose and I could quickly repair it on the spot and have the owner back into the fight. Those sewn by another 'expert' when the thread broke most of the sole came away from the vamp*. A repair was not possible as quickly. * on one occasion the sole came away, flapping loose during a fight causing the owner to miss his footing. Only the fighters' skills stopped there being a bad incident

-

parakeyner joined the community

-

A bit of a useless debate IMO and one that doesn't seem to be taking usage into account. I've never known a thread that simply holds two pieces of leather together to break no matter how it's sewn (bonded polyester/nylon). Can you snap a piece of V69 with your hands? If you can you have thick skin. Thread used under high stress conditions is different and is usually sewn inside a channel to avoid abrasion. As dikman said, I think a certain amount of ego comes from the S/S camp but you can say that about quite a lot of leathercraft and there's nothing wrong with it as long as it's not part of a strength debate.

-

135x16 apparently the same as 135x17 TRI

Wizcrafts replied to AlZilla's topic in Leather Sewing Machines

Labeling a leather point of any shape with a garment point designation is misleading. Leather cutting points tend to slice the fibers in cloth, webbing and serged patch borders. However, if any leather point has a snowball's chance in Hell of sewing cloth without destroying it, it is a diamond point needle. The shape is closer to round than the usual sideways slicing edge we have in leather points. I haven't tried sewing patches on with a diamond point, and don't recommend it without testing it first on a disposable patch with the same type of edging. I do use diamond/tri point needles on occasions when I want to sew close stitches that lay on top of leather projects, from end to end, versus S points that give a submerged appearance on the ends. -

ali234 joined the community

-

Darren, Greg died in March of 2021. Here is the notice.

-

AmyRF joined the community

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

You may wish to kneel down to royalty 👑 Just kidding , lol. I've been asked to judge at our perth royal show in the leather section in September, can't say no can I? I do remember trying my hand on mums potters wheel eons ago, it didn't end well , it does take quite a bit of practice, and concentration and the skin around the fore fingers and thumbs wear thin. At this point in time, no more dressing changes for dad , just some moisturiser on the op sites. I hear you about your suburbans, I have 3 land rovers, 3 tractors and a 64 triumph herald coupe that I so love to play with. I am ' resource rich but time poor' atm . I tell my customers, " I can make almost everything, except time " Take care, HS -

Edge beveling 101

RidgebackCustoms replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

For concave blades/rounded bevelers I use a straight piece of MDF and use the beveler itself to round the corner of the MDF. I then have a stropping block that holds compound pretty well and is perfectly matched to my beveler. Granted, using a beveler to cut MDF is not good for the tool, but it's a one time thing so the dulling it causes is minimal. Not sure I would use this trick for expensive bevelers, but for the cheap ones (which is all I have) it works great. Thank you! -

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Working on a potter's wheel and a propane-fired Raku kiln. Basically a 50 gallon drum with 2" of ceramic wool inside, lol, and one of my burners. I have a lot to do before snow flies so all my projects get a few minutes here and there. My daughter has given me another suburban the same year and make as mine so I'll be swapping some parts around, then fixing both up before hunting season and winter it will be nice to have a backup the kids can drive. I'm starting to get back on my feet after my ailment last spring, It was darn hard to get my muscle strength back, I guess old age is the culprit, I feel great now again and am back up at 4am every day starting out the day watching the hummingbirds have breakfast at dawn lol. Take care, my friend, summer is on its way to you now lol. -

Problem using a TandyPro Deluxe Leather Splitter

TomE replied to Coloradoguy's topic in How Do I Do That?

If you can't find a local sharpening service, you might check with Leather Machine Co. They offer sharpening of the hollow ground blade for their Class 14 splitter. @bruce johnson sharpens blades for Osborne manual splitters and might be able to help you out. -

I think I have the same Chinese skiving knife. It's a winner for the price. Another skiving tool I use often is this small round knife from Abbey England. The blade is 68mm = 2-5/8" wide. It holds an edge and is handy for skiving and for cutting egg points/English points on strap ends.

-

Micro Copper Burr Rivets - A Solution

TomE replied to Stagesmith's topic in Hardware and Accessories

Innovative solution and good looking results. Thanks for posting this information. -

I don't consider myself poor, but neither am I rich enough to be able to afford all the specialty sewing machines that are needed to stitch all possible seams. I have a basic, run-of-the-mill walking foot cylinder arm machine and that's it. I try to design things (or adjust patterns) in such a way that they can be machine stitched, but sooner or later I'll have to resort to manual sewing for 'difficult' seams. Not necessarily out of stitch strength or financial considerations, but for the esthetics. I think (maybe naively due to lack of experience) that most items can be created using the same machine stitch, but not all of those items will look pleasing to the eye (or be comfortable to wear) when there are thick seams (however thin one can skive them) and exposed edges (however fine one can finish them).

-

Need to sew patches . . . help!!

Darren Brosowski replied to Dwight's topic in Leather Sewing Machines

Contact Cowboy Bob as there are two grades of Chinese 29k machines and one makes a great doorstop. Buy from Bob Kovar or Greg at Keystone and you will get one guaranteed to work