All Activity

- Past hour

-

@Ferreol Helle Clément, and welcome to the forum I think the biggest challenge will be finding a machine and a needle that will accept a 3 mm thread. I have an old Singer class 7, but I don't even think that that machine is able to manage a 3 mm thread. A problem is that the bobbin won't really be able to accommodate much, and I doubt that such a heavy thread will be able to go around the bobbin itself without getting stuck. I just checked Gross Beckerts needle sizes for system 794 (the one that a Singer class 7 and others use), and they did have a needle called size 300, but it was incredibly expensive - around 20 times the price of a regular large size e.g. size 200. They wanted something like 420 $ for a 10-pack of needles. My best suggestion would be to use a thinner thread (linen or cotton) and sew through the 3 or 4 mm diameter linen and through the wool fabric. This might not be what you are looking for, but it would enable you to fasten a 3 or 4 mm thread to your project. Wool fabric of that wight, I think that you should technically be able to sew on a regular machine. But not with such a heavy thread. As an alternative to linen, perhaps you could use silk? I think it is available in qualities that you can use on a sewing machine. Best regards Jonas

-

I think the part # for the table plate is 202259, and the hook end on the machine is #210844. Same hinges are used on the 107W zig-zag machines. Googling those numbers pulls up a number of sources, and I think you can still get them from Superior.

-

Thanks! This one was with my own pattern. I've made a hat before with a pattern from Dieselpunk but the hat didn't fit right so I redesigned it. His cowboy hat pattern is to round so presses one the front and back but leaves a gap on the sides.

-

More like it mate. I'll do a search.

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

My little bbq . It's not very big, but it works just fine, and big enough for me and dad. I got a 2 ring gas burner for my wood fired brazier so I can at least have a barby, while my ol' bunky is being restored. HS -

- Today

-

No, this is just a twin needle machine with a jump foot. But it's going to be a treat not having it flop around on my narrow table.

-

Just a simple rivet size tube needed Keith. Where my dies have a wood core it would be simple to just drill a hole and glue a tube in to save working out where to punch every time.

-

Promethean_Sewing_Machines joined the community

-

Oleoleole joined the community

-

Hi, anyone know where you can source a bias binding foot for a Seiko lsw-8bl sewing machine in the uk? Do they even make one? material is 600d cordura binding on 500d cordura material thanks in advance

-

those look really nice! Glad you have the time to get back into leatherworking.

-

-

Older post but damn. That’s nice. Did you wing it or did you try out a pattern?

-

craftyman64 joined the community

-

Really great work so far mate and I know this was a request but I ain't having it until I see a handbag. If anyone knows where I can get tiny hollow tube that I can incorporate into my dies to punch rivet/snap type holes at the same time please let us all know cos it won't be long before dikman wants em too.

-

I need to store the deerskins that I have, as I try to determine how exactly to choose the additional deerskins I need for my next project, as no one here seems to know the exact answer to my question, asked in another thread. As I wait, I found a way to store the deerskins, that has not damaged the deerskins as yet. So I thought I would share it here for newbies in the field like me. Others might be using the same method as well, of course.. I need this way because I do not have space to hang them all up. I store my deerskins in large zip-lock bags, the ones I received clothes in, actually. I leave sufficient air inside to provide a buffer against the weight of leather placed on top and then zip it tight. The air inside prevents damage and give it air, as it were. Of course, I have not kept them in this way for long periods as of yet, but for short periods, it works. Deerskin is notorious for getting wrinkled, so this is an easy way to prevent that. You get similar large zip lock bags online as well. Come to think of it, other leathers that might crease could be stored in a similar way as well. Hope that information helps somebody.

-

Well, further time on the internet indicates that Blue Mountain Industries thread was a product of Barbour threads (the US company) that apparently went out of business 20+ years ago. Would still like to know if this thread is any good. Any insight appreciated.

-

Are those things hardened? If not once the the rust is gone heat it to blue-gray and drop in oil, that gives a nice finish and some rust protection.

-

@bruce johnson That's a pretty impressive collection you have there Bruce . Excellent job on their restoration . I have about 30 lasting pliers in my collection but have no cast bell type . To be honest i didn't even know they existed till a couple of days ago . I will now be looking out for a decent one to add to my collection .

-

This looks good to me! I absolutely love the little square in the stitching. I'd never get it that symmetrical.

-

Belt extension, tooled English bridle

KillDevilBill replied to DoubleKCustomLeathercraft's topic in Show Off!!

LMAO Don Gonzalez' method has never failed me, IF a big IF I'm given the correct information. Nice save! I think this looks great. Almost intentional. Gonna try and remember this when it happens to me.- 5 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Finished off the last of the dies for the four pieces that my mate is cutting out (he has been getting orders from a Single Action shooting club for suspenders that he makes and cutting them by hand is getting tedious). The dies aren't perfectly uniform but a little bit of sanding/trimming of the leather pieces should fix that. I used some "pretend" leather that I salvaged from my old Triumph saddlebags, not something I would want to use on anything. The Vevor press punched three without any trouble, the larger one took a bit of fiddling as I think I have a pronounced burr on the cutting edge. The press also punched the die fairly deep into the plastic cutting board!!

-

Veleska Fears joined the community

-

Thank you, AlZilla

-

Singer 111w155 stitch length issues

friquant replied to Glaciersew's topic in Leather Sewing Machines

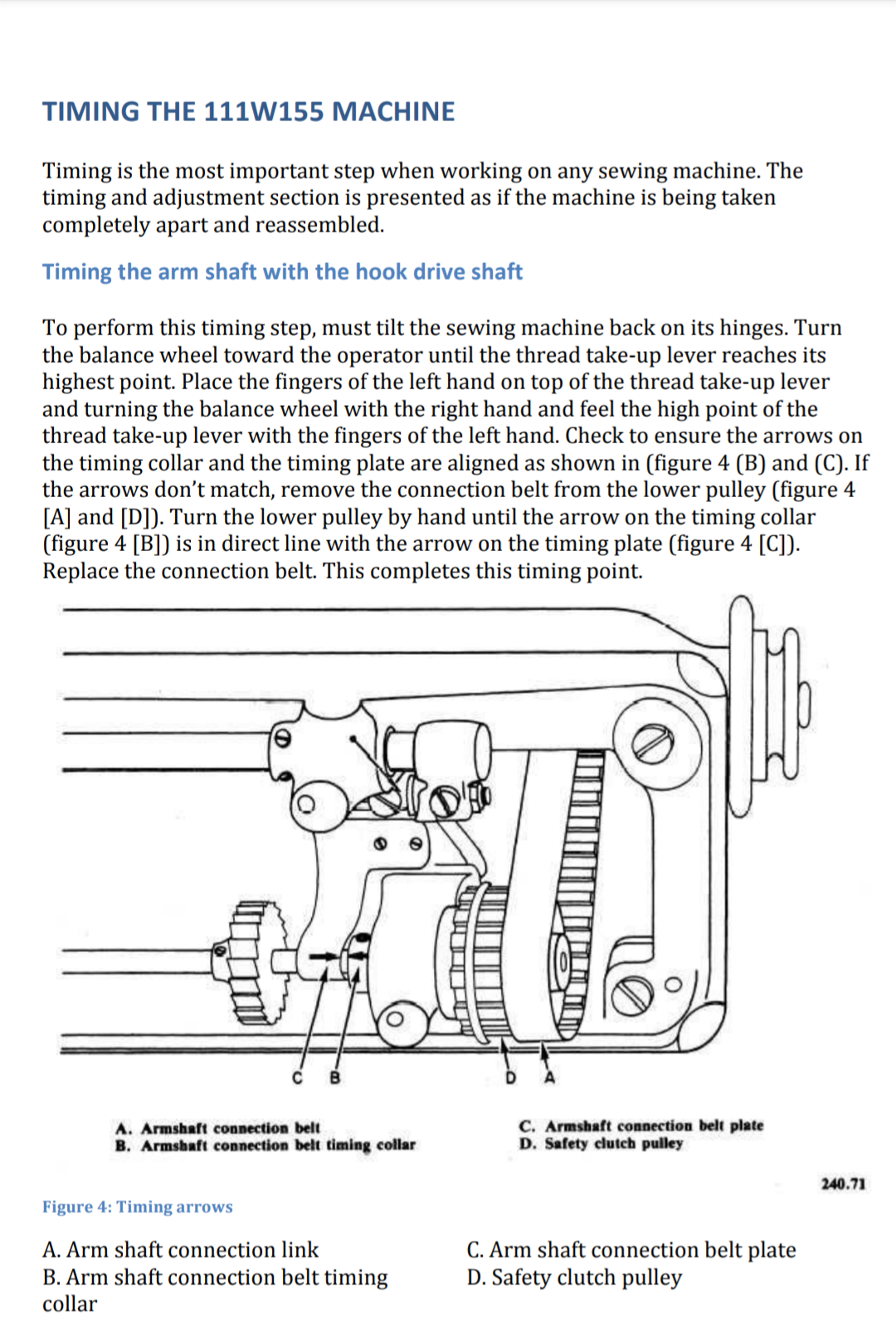

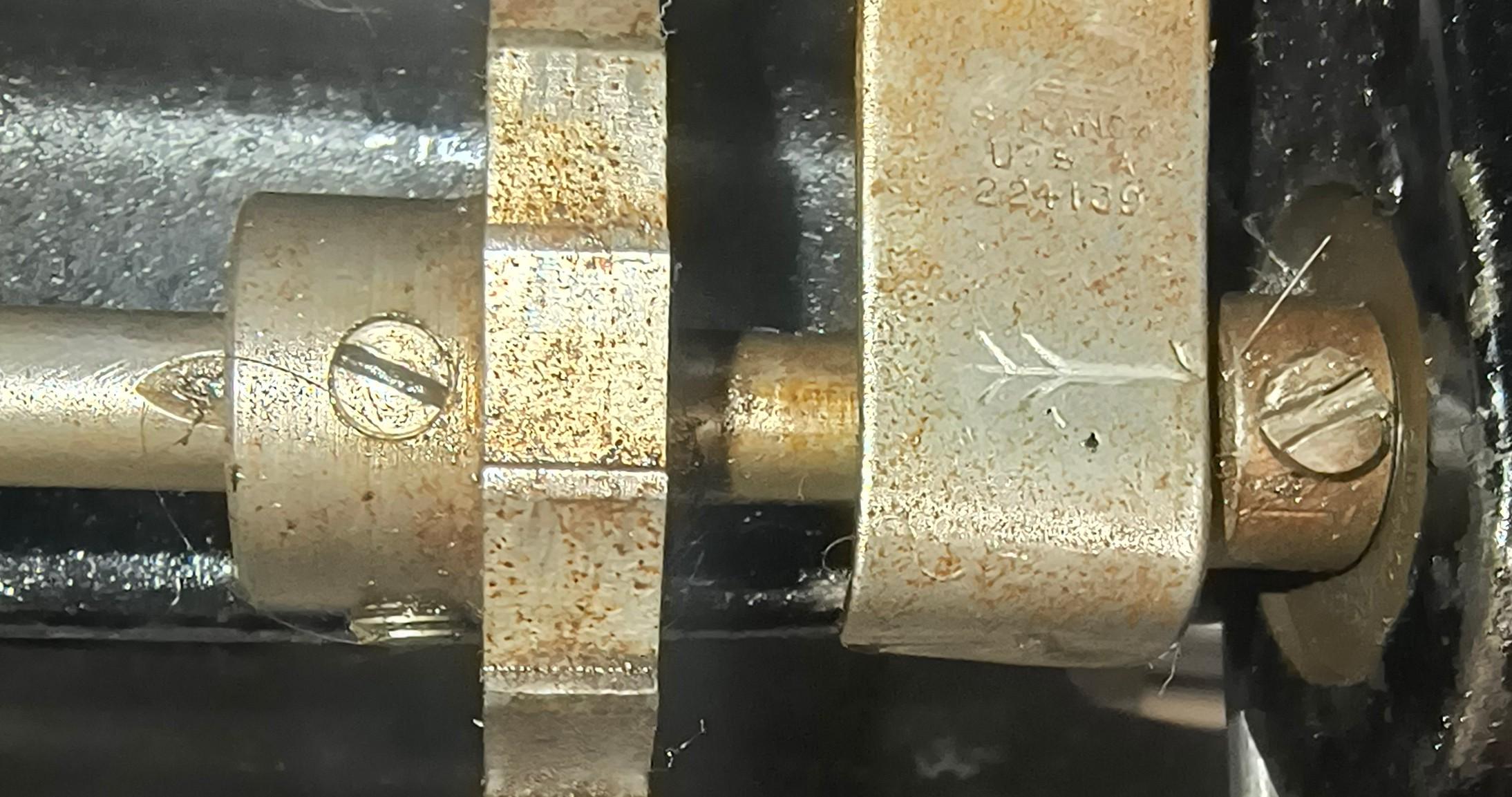

Looks like the belt is one tooth off. -

Singer 111w155 stitch length issues

cadet4x4 replied to Glaciersew's topic in Leather Sewing Machines

-

Old, Faded Saddle

Majolica15 replied to Majolica15's topic in Saddle Identification, Restoration & Repair

Thanks. -

Singer 111w155 stitch length issues

cadet4x4 replied to Glaciersew's topic in Leather Sewing Machines