RobDude30

Members-

Posts

160 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by RobDude30

-

Tips On Cutting Belt Slots?

RobDude30 replied to Sixer's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I use a 3/8" hole punch and a 1 1/4" wood chisel as well. I then use my Dremel with the small drum sander attachment to clean up the slot. -

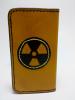

Nuclear Business Card Wallet

RobDude30 replied to RobDude30's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

It's supposed to be Homer Simpson - nobody seems to see it unless I tell them. LOL! -

Had a little fun with this one - it is made for an old friend that I haven't seen in a while. He works at a nuclear power plant and has always been a big practical jokester. I think the designs are befitting. As usual, cow on the outside and pockets, sheepskin lining, mission pig for the silhouettes. Dyed with pro oil dyes and hand sewn with Irish linen thread.

-

Question About Halter Making

RobDude30 replied to RobDude30's topic in Saddle and Tack Accessory Items

Thanks for that bit of info. I am learning as I go on this one and did model mine from a nylon halter made specifically for an Alpaca. It does seem to fit and work very well, so far. -

Question About Halter Making

RobDude30 replied to RobDude30's topic in Saddle and Tack Accessory Items

-

That is a great idea! I'm heading to the store this afternoon to pick up some wax paper.

-

Led Light And Spare Magazine Holster

RobDude30 replied to RobDude30's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the kind words, fellows. @Tomcat1066 - I think it is a great idea to be prepared. I always carry my handgun, but up until now have never carried any other "essentials". -

Gun Belt - Ordered Blanks

RobDude30 replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I make mine thick as well. My everyday carry belt measures 1/4" with the calipers. -

The guys above are much more knowledgeable than me, but I have a 1/2 cent to add to what they said. If you want to try to salvage the holster you made and make it usable and you haven't sealed it yet, try this - wet the holster again (not soaking, but damp enough to re-form), put your firearm in some plastic wrap or a baggie, and wear it for a few hours. You can unholster and reholster several times to loosen it up a bit. Work with the molding every so often if you need to. Your body heat will help form the holster and possibly make it more comfortable, as well as help with the fit to the firearm. When you are satisfied with the fit, carefully take it off, let it dry and you should be good to go. As the others mentioned 11/12 is way too heavy for what you are trying to do, but for the sake of saving a project and getting some use out of it, the above just might work. It is definitely not the preferred method of holster making, but I have used it in the past to salvage a holster that was uncomfortable and too tight.

-

Question About Halter Making

RobDude30 replied to RobDude30's topic in Saddle and Tack Accessory Items

Hi John, Thanks for the advice! I am sure I will be looking for ways to improve and will definitely heed your advice on the next version. I modeled this one after a nylon halter my friend had that was way too big for his cria. According to him this one fits well, but I haven't seen it on the critter yet. I'm sure this venture will be tons more fun before it's over with. Thanks again! Rob -

Question About Halter Making

RobDude30 replied to RobDude30's topic in Saddle and Tack Accessory Items

Here's the finished product (at least the prototype finished product). My friend is going to give it a good working out to see how it does. -

Rob here checking in from Covington. You guys are not alone! I have been playing with leather for a year and a half or so now. Improving slowly with every project I make and having tons of fun!

-

This one's for a baby Alpaca. Made of doubled 4/5 oz cow, USMC black dye, hand sewn with red Irish linen thread, finished off with Resolene. WAY too much sewing on this one - was very tedious and time consuming with all of the small pieces. I also had a hard time clamping it in my stitching pony which made the whole thing that much more difficult. Let me know what you think.

-

Question About Halter Making

RobDude30 replied to RobDude30's topic in Saddle and Tack Accessory Items

Thanks for the ideas. I think I will try skiving and over lapping on the next one. -

I, like most everyone else that started out their leather working hobby by going to the Tandy store, bought a bottle of Gum T. I have tried numerous times to find a good use for it, but keep going back to other methods that I've learned on this site that work much better (for me anyways). Now, I'm not knocking Gum T in any way as I know some use it with good success. I recently used some to lay down the fibers on the flesh side of a flashlight holster that I'm working on. I just used a dauber to apply it, and then burnished with a bone folder and some canvas. I have had some issues with it not holding up very well and it has the appearance of cracking. I guess it's possible that I put it on too thick?? I have had better luck burnishing using canvas with glycerin soap and saddle soap, then applying Resolene as a finish. YMMV!

-

A Good Stitch Groover That Not Too Expensive ?

RobDude30 replied to CustomDoug's topic in Leather Tools

I have one of the Tandy Pro Groovers and it does work very well. The only negative is that the adjustable arm is very long and hangs over your project instead of off the edge. This makes it difficult if you cut your grooves after the leather is molded (such as in a holster). The arm can gouge into the side of the raised areas. -

Multi-Tool/flashlight Holster

RobDude30 replied to rkleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Great job! I also like the compact size. I am nearly finished with a flashlight/mag holder pancake style and it appears HUGE. Haven't tried it yet, but have a feeling it will be uncomfortable. -

I think you will be fine as well as long as your bench is stable as someone else mentioned. I have a very heavy workbench (metal frame with 2" thick wood top) and use a large piece of granite tile 1 1/4" thick that came off the side of a high rise building downtown. It does just fine and doesn't move a bit when I beat on it.

-

I am making a halter for a friend's baby Alpaca and have a question. When wrapping leather around rings with no good way to use snaps or other fastening hardware, what are some methods that you all use to ensure strength and longevity? On my first attempt, I ended up with a seam in the middle and contact cemented the straps to themselves. I intend to sew the entire perimeter of all of the straps which will help some. I guess I could also use a couple of rivets, but that will still leave a flex point that could eventually fail. Any ideas?

-

Sold. Thanks!!

-

Mag And Light Holster

RobDude30 replied to Tnoisaw's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice job! Is that an LED light? I'm working on one of those right now, too. Hope to have it done early next week. -

I don't wet form the crease in my card holders either. I fold them over and run a brayer along the crease a few times. This will make it stay mostly closed and the rest comes quickly with use.

-

1911 - 3" - Leather Weight

RobDude30 replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This may not help at all in answering your questions but here goes: I've made exactly one avenger style holster (very similar to yours) and it was made with 6-7 oz. I have been wearing it for more than 6 months or so carrying my CZ-75 compact two-tone model with a 14 rd magazine (very heavy for something they call compact) and it has worked fine. However, with that being said, the fit has loosened quite a bit in the time I have been using it and at some point it may become too loose for me to be comfortable with it. I have since started making all of my holsters out of 8-9 oz (unless it's for a mouse gun). With the much lighter weight and smaller size of the EMP, you will probably be ok with 6-7 oz., especially if you can get a tighter boning on it. Hope this helps a little! -

Here's a place to get brewer's pitch. A lot of folks use that mixed with beeswax for hand waxing thread.