-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Knives, cutters, videos, books.... uhh.. just a thought here -- some of your money will need to go toward leather. Hey, don't laugh -- I've seen a number of people so determined to buy tools they spent all their money and had no leather to use the tools on! I've got some stuff around here I wouldn't mind givin' a youngster who was interested.. just send a message if you want it.

-

The "bunching' brings up a good point. I've tried a bazillion ways to make belts. I've done them straight and curved. I've done them smooth and tooled. I've done them single layer and laminated. I've done them flat, I've done them in a hat Take that 2-layer belt for example. Glue it flat on a table. When you wrap it around the waist, the inside layer "bunches" to some extent (and while less obvious, the outer layer stretches). This causes visible issues on the inside of the belt. Which, as long as they aren't extreme, aren't a big issue. Now, make the same belt, but glue it on a curve similar to the curve of someone's waist. Since the pieces were glued on this curve, there's no visible marring. Not to be confused, though --- the inside is still compressing and the outside is still tensing, they just aren't as obvious because the (2) outer bends are allowed to stretch more to "come around" rather than compressing the inner surface. Either will work. The "problem" then, is that the pieces will try to return to the position they were joined. On the belt which was glued flat, it will attempt to return to flat (much like a flat steel spring tries to go back to flat when bent, and why you can "snap" a comb) which does little damage to anything. This "spring" will relax over time. On the belt formed on a curve, it will try to return to that curve. So when wrapped around the waist, the inside layer which was already compressed someone suffers little effect. But when straightened (trust me, the nicer the belt looks, the more people will want to hold it out flat to "look at it") you are now stretching the inside surface beyond where it started, and you are compressing fibers which were already stretched, very possibly creating wrinkles/cracks in the OUTER layer, or at least in teh finish applied to the outer layer, which is going to be visible from now on. Point is, it matters both what you are making and the way you are making it...

-

On the utility knife and strap cutter, me too. The only benefit I found of a head knife or round knife was being able to say I have one, which is of no value at all to me. Oh, it will help you get rid of $100 US dollars (give or take) if you have too many of those your way But a $5 utility knife and a straight edge makes a nice line on one side of a leather hide, and a strap cutter (little hand held model) makes straps pretty quickly. I am, however, the dissenting opinion on why-tube (which is named because WHY would someone spend hours and hours of their life weeding through crap ...). Which is not to say that there isn't ANYthing useful there.... but in all the videos I've seen and had someone recommend, I actually found use in about 3 of them (and one of those was cute girls in a country music video ). If the aim is to make a bit of money and kill a little time, that can be done easy enough. If she'd like to go past that "bop it and slop it" routine, then you'll want to learn to recognize good leather, and how to gauge the moisture content of it for proper leather working (which I imagine can be taught by video, but I don't know that it has been). You'll get people on about letting the leather dry until "cool to the touch" (because they heard someone say that before)... but completely dry leather will be "cool to the touch" in a room which is 68°F., and thus means nothing really. By the way, sewing leather isn't completely different from sewing fabric. I'm no sewing expert by any stretch, but have done both. The machines tend to be heavier and more rugged, it's true, but the idea is the same. So I would actually offer TWO pieces of advice: Ask questions, but weigh the answers

-

It's going to depend on what you're calling "molding",and where the shaping would be. And when I hear molding, I assume we're talking about vegetable tanned leather (just to be clear). So, if I'm shaping an object and relying on it to hold it's shape without wet forming, then I'd line it after forming. Examples include a handbag, where I want a flap to remain closed when teh clasp is opened. I would glue the layers "on a curve", so that it naturally wants to return to that closed position. Or a gusset on a case -- I form turns and corners before lining them.. since I don't want 'puckers' and 'boogers' in the corners, especially if there are zippers involved. In this case, I likely don't even wet the leather to form the bend. On the other hand, if I'm wet forming, I assume it's likely because 1) it's a fairly complex shape which all layers have to fit, or 2) it's a spot where I'm not going to be able to put in a lining once it's formed.

-

Because the shipper is acting as your agent. Though not an "employee" by legal definition, they are - though temporarily - working for you. When a contractor uses a subcontractor (who is by legal definition not an "employee", and that subcontractor causes damage (destruction, delay, whatever) does anybody believe that the original contractor isn't responsible? Of course he is. Now, he may seek reimbursement for his damages from the subcontractor he hired (just like I would from teh post office), but the person getting teh work done is coming after the contractor they hired, not anybody who he paid to help get the job done. If anyone really believes that this is reasonable, try mailing the mortgage payment. If for some reason the bank doesn't get it, just tell the bank that's too bad... I mailed it, it's out of my hands, so too bad / so sad for you. Good luck with that. For me personally, I was willing to pay for shipping (even though I knew that was more than twice what the shipping should cost). But I dont' want to hear somebody ask me to insure a package twice (priority insurance, plus some other "insurance"). And I certainly aint gonna listen to somebody tell me that I may or may not get my order .... I just clicked on out, and that stuff can sit in that shopping cart forever. Well, probably just till a while after I've moved and the email address is no longer valid and starts bouncing emails back to them ... OH>. from teh other side of the coin, as a seller, if it happened once (it has, just not this year) I would just "take the hit". If it happened with any regularity, I would assume I need to find and use a different method of shipment.

-

Yeah, I been snoopin'. Price for those things is all over the map -- I saw the same clip on a dozen sites from 75¢ each to $6.00 each! That little S/W, she wants to be able to use it without a belt, so I could go with a clip (if there's one that will fit) or even a paddle (which would be easier to arrange). Opened my mouth and said i'd do it, so I'll do it - one way or another

-

Each person / business / supplier does things their own way For me personally, if I pay for something but I don't receive it, they'll hear from me. If that doesn't work, they'll hear from VISA. If in the end they wish to involve lawyers, I'm okay with that too I suppose... just seems easier to order from someone NOT intent on telling me that my hard-earned money just went into a crap shoot and I may or may not get what I paid for. I mean, if there's "nothing wrong with it", then why do you never see it stated that way? What they mean is you send me money, hoping to get this here thingie, but that may or may not actually happen. So why do NONE of them say that? I've done pretty well with the post office.. only one misplaced package in the last 10 years, and two total in over 20 years. One package they found and got it back on the right path. The other was destroyed, and they paid me for it in full. So, no complaints there. But if a package I sent goes missing, or damaged, I don't see where it's the buyers "problem". Shipping insurance is for the benefit of the SELLER, actually. I haven't read the civil code for every state -- and I don't intend to --- but I think you'll find something to the effect of a contract not being enforceable if it contains clauses which are not otherwise legal (this is why you see paragraphs included about "severability"). Someone cannot legally "agree" that they understand they may get nothing. if I order something, I will get either my money or my purchase. But that's just me. Thanks Madmaxx... new place for me... searching for different styles of clips.

-

Yep, simple. And I've asked about this in more than one place -- the response is they shouldn't have to pay for it. I know most places add teh cost into either the shipping or the item price, and that is fine -- I expect to pay shipping charges. But don't ask me to pay shipping charges, then tell me 'not our problem' if you don't get it. I think there actually ARE merchants ignorant uneducated enough to think that they can actually get by with this (and they can, if you let them). Most, though, I think are hoping you won't know your rights. So, this topic not about bashing any one (or more) supplier, so much as about informing the buyer. USE your card, and the protections built into it. Good for you and your order, and good for all of us in the long run. Strange enough, in this instance, the shipping was about $7.50, which I know is sufficient amount to send that small order priority mail, which would automatically be insured up to $50 (actually, mine are insured up to $100) just for using priority mail (no added charge).

-

Yet another one down in flames. Thought I'd order some hardware - holster clips, paddles, screws -- so I signed up for yet another site (knife kits) only to get a message at checkout that they won't be responsible for lost packages. This, apparently, has become the new norm. I know I could call my credit card company and basically"break it off in 'em" over paying for something and not receiving it. My card company would charge back, and I'm guessing repeated instances would result in fraud charges. Still, I'm just not doing business with people who do things that way -- just don't need the headaches. One more place down...

-

Just a bit of FYI.. in the process of searching for other styles of clips, I find the best price on these (short of buying in some bulk) is at http://www.holstersmith.com/vcom/index.php?cPath=547

-

Classic Western Holster

JLSleather replied to LumpenDoodle2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I LIKE it. I tool quite a bit, and often fairly intricate. But this has that "hammered copper" look.. almost like engraving... that really "works" here! Oh, and I should add I like that stitchin' too.. -

That looks awfully loose. Maybe if we could see it with the gun IN it? I like to see a holster FIT a gun, like ... no room to flex and "smoosh". No wrinkles, front OR back. "extra space" between the gun and the stitch line won't take long to become a wet noodle. Just gonna tell that gal her holster can't be done with hardware currently available to me. Maybe make her one with TWO clips.. ahead of and behind the pistol.

-

Granite slab 12"x18"x4" for $20 bucks... worth it?

JLSleather replied to myjtp's topic in Leather Tools

Tha's a good deal.. the delivery is likely worth that A chunk for tooling .. about an inch thick is enough IF you have a solid table under it (no flex). 2" thick is more common, probably, and works great. 4" thick is NOT necessary, but then it won't hurt anything either.. and at that price I'd likely pick it up "just in case". I like a wider slab because belts lay nicer on one at least 2' long, but that isn't "necessary" either. -

So what keeps the leather from pushing down when this "form' is removed? WHAT web site?

-

Offset is "about" 3 oz

-

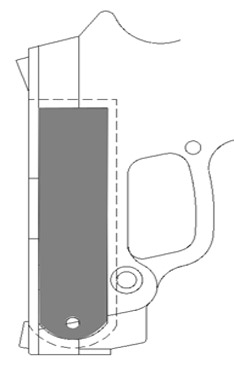

That IS the correct model. But that buton isn't recessed, it's raised. Here's a holster I made for it in another style, at another time (note the 'bump'). But, my big sister is in town, so I'm off to do lunch ...

-

Been there.. years back, had some junkies take a box which was being shipped. Box big enough to ship yourself in, but never got to the right place. Insurance pay for the $$ amount, but some of those tools are tough to find these days.

-

See, now there's some actual thought! I considered something like that (though I don't have the means to "plate" anything), but I don't want it weakened right in that area. Here's ONE OF the issues... Gun is about 1" wide between the laser toggle and the top of the slide (you could call it 1 1/8" to the top, past the radius). Clip is 7/8, plus 1/8 on each side to stitch a retainer, there's yer 1 1/8 max. But the toggle would be riding right down the vertical stitching every time the gun is taken in or out...

-

What's to "get"? Not my forum, so not my call who says what, or when. When I do post, I actually like to encourage thinking I don't know that guy (and next month, I still won't), so . Post to not answer seems strange to me. I suppose I'm unlike some others in the sense that when I ask a question, I really am interested in an answer -- not simply killing time or begging attention. In fact, maybe somebody could fill me in on how you "rotate the laser" out of the way on a S/W M&P Bodyguard?

-

Interesting... I haven't scratched my head this much over a holster design in.. well - maybe ever? Can't find a usable clip less than 7/8" wide, and this little gun doesn't allow room for that...(before piping in, guy might consider that's 7/8" PLUS space to attach it).

-

No marks? SUE WEEEET... you got the only one Does look like more than one color, though ....

-

So that's one "no". I admit, I never did "get" why someone posts to a forum to say "i don't know ..." Actually, ya know...I think it's unlikely - so I'll just go on lay one out myself

-

Skiving/splitting and finishing an entire side

JLSleather replied to theoregoner's topic in How Do I Do That?

I've never sent a message. I just call them ( 800-325-7950 ) and tell 'em the weight I want. -

Anybody seen one of these done... simple owb clip on for the bg380 with a laser? I've seen a few done, but not one done well. Got a gal who wants one, but I aint seein' how to keep the clip from interferin' with the laser toggle.

-

Stitch Quality On Sewing Machines

JLSleather replied to fenceguy1984's topic in Leather Sewing Machines

Hand sewing -- despite long winded videos and a bunch of people who want to use stories of their "vast training" to inflate the price of simple goods -- doesn't take that long to learn. Years ago, I bought Stohlman's book, got the tools recommended in it, and went to stitchin'. These days, most of my sewing is done with a machine - except those times where it's simply easier to sew than to set up the machine, or if someone should request that (which never happens, almost), or if there is something which simply won't fit in a machine. I've seen both machine and hand sewn projects which look great. And I've also seen both which were clearly sub-par (pronounced krap). Bob (Kovar) can no doubt fix you up (in teh Toledo shop you mentioned). 4 layers of 9 oz sounds like 1/2" thick, which may be at the top end of teh 3200, but--- ask Bob to confirm. My opinion -- pay no attention to those on about "hand sewn" or "machine sewn", and look instead for WELL sewn!- 10 replies

-

- sewing machines

- tippmann boss

-

(and 1 more)

Tagged with: