-

Posts

7,391 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

My buddy uses those slide things used for playing the guitar ... little plastic tube thing. I could never get the hang of them, and that athletic tape idea is sounding like it's worth a try ...

-

New Notebook Folder

JLSleather replied to Double U Leather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Tha's just funny ! I don't have photos of two of the same thing where I used antique on one and not on the other. Much of that stuff gone in the computer theft (hard to back up files when they took the computer AND the disks). And I can't even "do one up" , cuz I don't HAVE any antique finish. But I can sorta make the point here with a couple of other things. THING !: Here's about as close as I've come to that sort of thing (personally) in quite a while. #1 dyed and oiled, then tan-kote. No "resist", no buffing, no problem. Just put the dye where it goes and be done. #2 dark brown leather STAIN (which I felt compelled to try). applied to the basketweave design ONLY (deliberately NOT on the dark brown dyed border OR the oak leaves) wanted to see the distinction. This effect I can live with, though not my personal favorite. Even with this, you can see how the natural leather "lifts" more than the stained area, though nothing is actually lifted. The rest of my point can maybe be shown best from the original post, though a larger pic would have been easier .... More in a bit... Okay, thing 2: I've copied, enlarged, and cropped the original photo. This is the lower left of the front panel of the notebook, and I hope it was okay to do this Notice the line of "slime" left behind along the outside of an otherwise very nice border. NOT good. And you can't miss the "puddles" left in pretty much every depression on the project. I call them that because we've all seen a mud puddle - then the sun comes out and leaves behind this sludge sitting in the holes. Is that ribbed "thumbprint", or lined, or smooth? Or checked? You can't tell - the effect he was getting is now buried in the puddles. And all the cuts he spent so much time putting in are now filled in with cake. This "finish" serves to darken the deep spots - it's that simple. So, instead of "resisting", then antiquing, then buffing, then finishing again - only to have your entire project darkened (ruining the subtle colors, if you used them, and blending subtle shades and natural leather) why not just put the dark where it goes and leave the rest alone ?#$@&*! In fact, back up just a bit ... if the leather's moisture is right, then the tools will create their OWN darkening (fancy folks call it "burnish"). SO -- here's the thing for any English speaking folks. I think we all appreciate ( I know I do) your injected humor taking the edge of what was supposed to be a helpful suggestion. Guess I should have put it this way in the first place .... I think the guy's carving looked TOO GOOD to go dumping that stuff on it. -

New Notebook Folder

JLSleather replied to Double U Leather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Sweet and sour review here (wife says I'm argumentative, but I disagree). The design and tooling look GOOD. But I've always hated that antique crap. Looks like what's left behind when the spring flood receeds, and I think it RUINS a perfectly good carving. Originally, it was the lazy man's color shading. So here's the thing ... this turned out "Okay" because the tooling looks good. BUT, if you're willing to take the time to tool all of that, I'd sure like to see you SKIP the antique (which I think is French or Latin for "crap"). I think you'll find the design looks SO much cleaner and nicer. Don't take this wrong, I think you got a nice lookin' project there. I just think that for LESS money and LESS time, it would look EVEN BETTER. TO be clear, I don't mean you did the antique wrong, I meant that antique should never be used. By anybody. Ever. -

Woman's 3 Fold Clutch Purse Thingie

JLSleather replied to Double U Leather's topic in How Do I Do That?

Talking about these, or some other style? -

http://cgi.ebay.com/VINTAGE-LEATHER-CLOCK-CARVING-PATTERN-/190477237889?pt=LH_DefaultDomain_0&hash=item2c5953fe81 From Ebay, right now.

-

Seriously? Can This Leather Even Be Used?

JLSleather replied to ShortBBL's topic in All About Leather

I don't do a lot of holsters these days. No objection to them, just not so many requests for them. You guys must be doing them too well I have, though, made some pretty nice holsters from shoulders. THE nicest one - I think - was a double hip western rig for matching long-barrel .44's (target pistols, complete with scope) AND the belt to carry both. I found a 14 sqft shoulder of 9/10 that cut all of it - and not much left. Now if I can quit reminiscing long enough to answer your question. I think folks like shoulders for holsters - not so much that it's a better cut of cow (cuz it isn't necessarily) - but because it's fairly economical. Shoulders let you cut squares/ rectangles / straps without a lot of waste. Backs are generally firmer leather, better for tooling / forming,. Sides are cheaper per sqft, but then you have one shoulder and one belly. The shoulder might be okay, but I think the concensus is that belly shouldn't be used for anything that is going to take stress (or carry a load). I say "generally" above because there's always variation. As a rule, if they're all cut from the same hide ... firmness in the hide will be bends, backs, shoulders, well, that's about it. I don't have much use for bellies or neck, which both tend to be spongy. I don't generally buy sides, because I know I'm paying for 5-7 sqft of belly I don't want. Same reason I buy boneless chicken - I know it costs more, but by the time I throw out the part I don't want it's the same thing, only somebody did the trimming for me. For what it's worth, about a week ago I ordered ONE side from Wickett / Craig. First order from them and wanted to see what I get. I called, talked to some lady about what I wanted, and a few days later got exactly what I asked for. And this "special" grade (which I guess would be a "B" or a "C" on someone else's list) is just fine - certainly better looking than your photo. About $5 / ft (delivered). Not sure what you mean by "untanned", and I haven't used the HO (which gets great reviews around here). -

Tough to say without knowing what you're trying to do. Too close that a lacing "nipper" won't do it?

-

Seriously? Can This Leather Even Be Used?

JLSleather replied to ShortBBL's topic in All About Leather

Yes and no. Yes, those are fat wrinkles. Actually fairly common on shoulders (and neck). But that's pretty bad. And no, you can't "color" them out. More than the wrinkle appearance, I'd be concerned about stretch. It looks "mooshy". -

SUEEE WEEEETTT .!! News gal says "over 100 hours" in a saddle. Hmmm ... adds some perspective to those comments of folks who claim 100 hours in a wallet or handbag ...

-

I went to Etsy yesterday and just typed "tooled leather" in the search from the main page. 1100-something listings of some of the most hideous "crafting" you'll ever see. Of over 1100 listings, I saw about a handful of items that didn't cause a gag reflex. They weren't especially nice, they just didn't make you sick. Then, I didn't view all 1100 .... just maybe a dozen pages, and into some of the "shops" where these were sold. I was surprised to see some of the stuff people will spend their money on. Guess that's never gonna be my thing. Reading through the "stuff", Etsy recommends talking up your items on facebook, youtube, myspace, yerspace, whatever ... which I don't do, and I'm not going to. Apparently, the concensus is that if you talk about your pathetic, hideous, and often unnecessary item enough then someone will buy it (I've seen spongebob, so there is apparently some truth to this). One thing they said I agreed with, though ... if you're going to make stuff, it should be a product you like. But then, it's no longer about the money at that point.

-

From the old days - when I iused to work for a living - the force required is equal to the length of the cut (inches) times the material thickness (inches) times the shear strength of the material (tons). In other words, F=LxTxS It matters how big a part you have. If you're cutting 10 oz leather, then your "T" = .160" (or so) and your shear is 1.5. Those won't change much (some leather a little "firmer" than others). So you can combine those two right from the start, which gives you a simpler formula ... now you know that the force you need is .24 tmes the length of your cut. If you want a little "padding" on the force (which is good) you could figure on a press that lets you DOUBLE that, now you have .5 times length of the cut. This is faster, safe, and reliable. Now, with all that long-winded crap, here's the point about the size of your part. 3" diameter circle: length of cut = 9.42, tonnage = (9.42)(.5) = 4.7 tons 6" diameter circle: length of cut = 18.84, tonnage = (18.42)(.5) = 9.4 tons Wallet back; length of cut = 25.25, tonnage = (25.25)(.5) = 12.6 tons 9 x 12" notebook (one side): length = 42", tonnage = (42)(.5) = 21 tons This is an educated guess, and will put you pretty close (keep in mind those numbers are DOUBLE what you should need). Normally, you want to go up one size heavier than you think you need, because of lots of factors. Wear in the slide, firmer leather, dies not dead sharp, all increase pressure. More down to earth example, if you need to get to the store for a loaf of bread, you could buy a Porsche. The Porsche will work to get the bread, but did you really need to invest $50k ?

-

It's thinned. We just discussed this, so I'll let you follow the link instead of clogging the system with a repeat OVER HERE

-

I use an airbrush most of the timie, but I think your coloring is just fine Nice work!

-

Neat idea. Just wanna make sure you check for hydro leaks every so often before you put the pricey stuff in there .

-

Too kind, Ann, but thanks Personally, I prefer natural leather with a hints of color. Hate to see perfectly good cow all painted up. But, my wife says - about 2 or 3 times a week - kaint just make what I like. So, the dark leather was her idea, actually. I have 16 bottles (1 0z) that I have stuff pre-mixed in, and 4 more (same size) that I have around for mixing the stuff I'm just gonna use once (I don't do lots of purple, but even I liked those purple orchids that lady wanted). This is why I say "about" 4:1 or "about" 30:1 ... I know some of the reducer is evaporating when the bottle is open. Bottles are about 1 3/8" diameter, I git the dye with droppers. They're about $2 / 5 pack at hobby lobby, and I keep them separated - one for yellows, one for reds .... etc. All of it sits in a small drawer in my bench and slides shut out of the way when I'm tooling. Just for information, the bottles I use are 1 oz glass bottles by Paasche, who also makes the airbrushes I use. Hobby lobby has those, too, or you can get them on Ebay for about $1 apiece. Glass bottles will clean out very well if you ever decide to clean 'em, and you can use them with the airbrush if you care to (I don't - too much weight for me when I'm trying to be able to move around). The "thingy" posted here is all done with shades of those 16 colors, though some of the shades are more than one color painted over the top of another. I post it here so you can see what the 30:1 blue looks like (sky, water, fisherman's jeans, and lightly on the distant mountains).

-

"No One Will Notice!"

JLSleather replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Ya gotta nice lookin' piece o' cow there. Personally, I'd either replace it - or not - with no mention to the customer. Your wife's prolly right ... proll nobody cares. Only question to ask ... does it bother YOU? -

It's only because both exist that there even is any confusion. Wife is from New Zealand, and mostly uses "English", because the butcher would have us committed if we asked for 60 grams of sirloin. She's better at it than before, which is good cuz the speed limits are in "English". I know that 6 mm = .234 inches. I always remember that because I spent 12 hours one night drilling out two dozen 1/4" cap screws that some genius forced into 6 mm holes in a hardened die block. If we had JUST metric stuff, I wouldn't need to remember the conversion, So, go with just ONE ... and the one the rest of the world uses is metric. Should be easy enough ... me 'n' the kids LIKE the idea of going down the road at 100 (k).

-

I thin almost everything... only dyes used full strength are black and chocolate. These colors I want to leave rich - usually solid colors. Some of the colors are about 4:1 (solvent to dye), others much more. I buy "navy" and thin it about 30:1 to simulate skies, water, and denim clothing. Put the navy on full strength - even with a "dry" brush - and it's nearly black. And it's easier to blend. The Fiebing's dye is basically little flakes blended in a solution. Thin it out (more solution) and you can cover more area quickly and I think it's easier to keep it "even". One more (big) reason for reducer is I can get different shades of one color without changing the color (chocolate and dark brown, even full strength, are not the same shade). Photo below is dark brown dye (only). Background is about 1:1, design is about 10:1. Same dye bottle, though....

-

When I have the time, I tool all day. Every so often, I do get out of the chair for a minute for phone, restroom, whatever... seems to be enough. Only pain I get is every so often - seems like after 9P - bit of discomfort in the base of the skull, usually due to the wife being tired of the taptaptaptaptaptaptap........ Seriously, unless I'm doing very large projects, I like to sit until it's done. Leather only gets wet ONCE.

-

Other way around ... this is to prevent hardening. When you wet / case leather, the water evaporates out. When the water goes out, it takes some of the oils with it (just like human skin). General rule, the faster it dries the more oil lost (much like a sunburn). Neatsfoot puts it back. Couple of other benefits too, but it's early ...

-

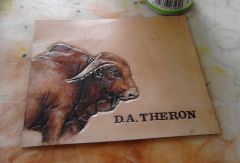

Afrikaner bull. Just to show that I do carving, not only painting...

JLSleather commented on Anet du Toit's gallery image in Our Leatherwork Galleries

Not sure who didn't like the "just painting" you mention, but I peronally ADMIRE your work. There will undoubtedly be those - here or somewhere else - who will be offended by the fact that you get better definition with a paint brush than they get with stamps ... My wife really liked your cats specifically. This is a big deal, since she doesn't like anything ... -

All a matter of personal preference. There are unlimited combinations of color and method, so it becomes a matter of the look you want and the method you're comfortable with. Examples ... I use Fiebing's spirit dyes, and usually in an airbrush. This is more for speed than for effect. I use brushes (red sable hair) to get the look I want at times, and the look and the technique are different even though it's the same dye. I don't use acrylics at all, but I've seen VERY nice work by those who use acrylics. One large difference is that the acrylics tend to be more opaque, as a rule. If you put light blue spirit dye on "yellow-tan" (natural) leather, you'll get a greenish tint, because the natural leather "adds" to the color of the light blue. Light blue acrylics tend to cover the underlying color - even when thinned - and will result in a more pure light blue. Keep in mind that this comes from a guy who has tried various acrylics on different substances - and in the end chose the spirit dyes for leather. For what it's worth ...

-

Thin Kit Leather Vs What I Have To Practice With

JLSleather replied to bkingery's topic in How Do I Do That?

Yes, it is. This one I couldn't do that, but I thought I'd pop in to say that I received that hide from W & C - very nice and more than reasonably priced ($125 to the door). -

This may help ... Green arrows: Bevel these lines on out. They should fade gradually. Red arrows: Fade these impressions. It looks like a shader tool was smacked right there, though it should look like a depresson in a 3D flower. This is common, so don't let it drive on you - just to be aware. This is the same "type" of carving ... admittedly "down and dirty" for the purpose of this conversation. One side shows it tooled only, you can see how the impressions gradually fade out. The right side is hurriedly painted, just to maybe make it easier to see. The PAINT fades out, too. I threw "stops" in there where the stem sections meet, but I usually wouldn't. Just giving you another idea ...