-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Sweet video Uwe, love the way this is put together.

-

Taking TK-8BL Sewing Machine

Gregg From Keystone Sewing replied to RhodesAveDesigns's topic in Leather Sewing Machines

I've seen a few of these, Hoffman Bros. used to bring this machine in as an EA-106, the quality is good. -

Foot lifter solenoid... how?

Gregg From Keystone Sewing replied to R8R's topic in Leather Sewing Machines

24VDC, 3.0 Watt will do it. -

Foot lifter solenoid... how?

Gregg From Keystone Sewing replied to R8R's topic in Leather Sewing Machines

Typically, this is working off of a 24 or 30V power source, normally controlled by a motor control box. Usually, heel back on the foot treadle, with the correct controls, will input signal to the motor, and the motor will then send the signal to the solenoid foot lifter. Many motor will perform this, but common names of motor brands are Efka, Ho Hsing, and Mitsubishi. Some less expensive motors have a 24 volt output as well, but they are not common. Consew has or had a 220V single phase model that had the output feature, CS4002 is the model. This can also be done using switches, say a mechanical switch hooked up to the foot treadle and then connected to a 24 or 30 volt source that will fire this off. I have a terrible image attached, but it may be enough to show a common foot lifter setup that we would use this for. -

Here are two bobbin winder winders that will not work unless the hole is there, this is from An Adler 266, as one example. This bobbin is used all over the place on many machines, and this one is my standard. I'm quite sure you can get other off brands that will work correctly as well. These are not magic bobbins.

-

These bobbins can be a real problem. I usually like to sell genuine Durkopp Adler steel bobbins. Bobbin dimensions are important, but also important are where the holes on the side of the bobbin are located and the size. The reason is that many bobbin winders will not work with the bobbins if the hole is not made in the correct location and with the correct size hole.

-

Singer industrial machine model 281-24

Gregg From Keystone Sewing replied to hollyobrien's topic in Leather Sewing Machines

That's the one with the factory cloth puller correct? -

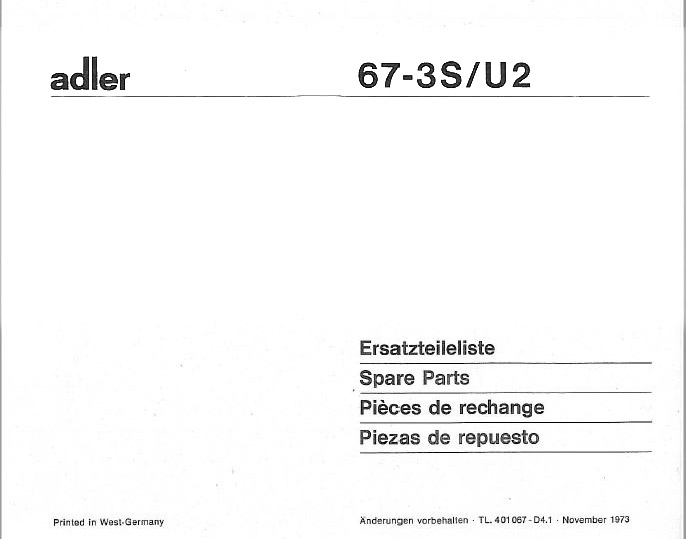

When was my Adler 67 made?

Gregg From Keystone Sewing replied to chase97's topic in Leather Sewing Machines

News to me, I would have never known that, many machines have GK in their model number. -

When was my Adler 67 made?

Gregg From Keystone Sewing replied to chase97's topic in Leather Sewing Machines

Uwe, Please feel free to add escutcheon pins to your vocab, see below, we use this to denote a type of decorate pin. I learned somthing new, too; the eustachian tube connects the middle ear to your throat. I never new that at all. Glad to share and learn, that's why I'm here. All the best, and I very much appreciate you Uwe and all the work you do here and on YouTube. All the best. -

When was my Adler 67 made?

Gregg From Keystone Sewing replied to chase97's topic in Leather Sewing Machines

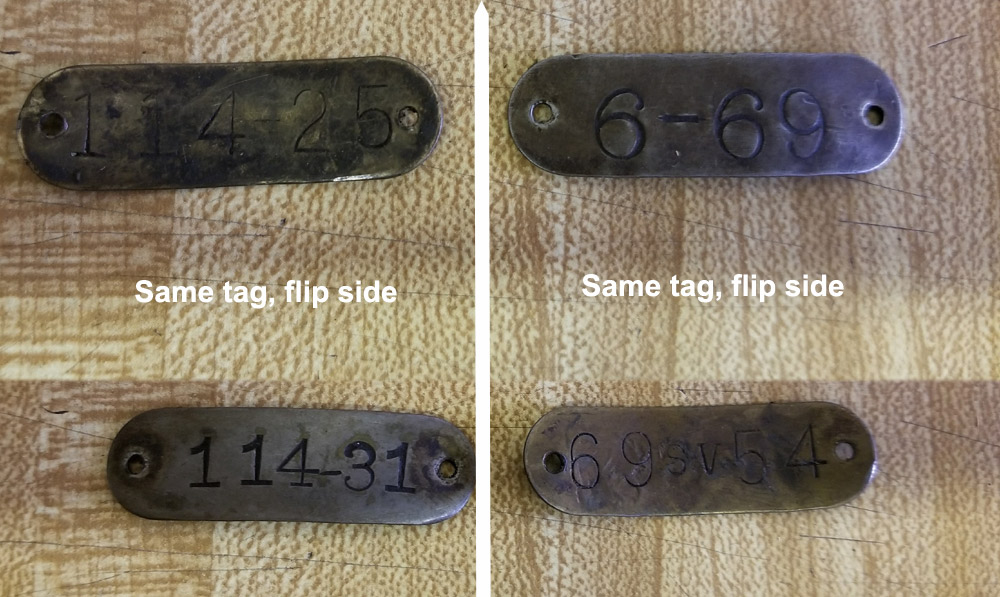

OK, sure, maybe that is the case, cheating a customer could be the point. Or, it could be something else that is VERY legitimate, something simply as recycling a model tag. As seen here, a 114 subclass was changed, maybe correctly to reflect a change in subclass and parts? Not sure. 68 and 69 class machines have literally dozens of sub classes, and would be common to change the model tag to reflect this. So when you seen tags switched or changed, it's not always to dupe or flat out lie to a customer, there may have been many various legitimate reasons to replace the tag. -

When was my Adler 67 made?

Gregg From Keystone Sewing replied to chase97's topic in Leather Sewing Machines

You can see the two different Eustachian pins, Singer would never send a machine out from the factory like that. I would bet one US dollar that if we flip that brass plate, that there is a different model number on the other side. Actually, it's pretty common, and if you remove enough of these tags and have a collection, you would see it for yourself. -

When was my Adler 67 made?

Gregg From Keystone Sewing replied to chase97's topic in Leather Sewing Machines

-

Question on Ferdco 900B

Gregg From Keystone Sewing replied to Big Sioux Saddlery's topic in Leather Sewing Machines

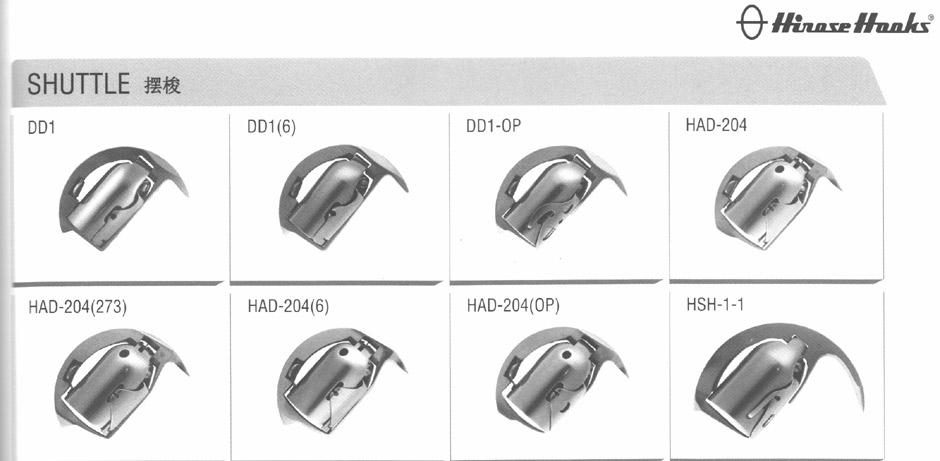

Bob did a pretty good job on this thread about open and closed frame shuttle hook, CLICK HERE These hooks are available, new, and like said, I'm not sure what hook came from the factory, the open or closed frame. It almost could have been whatever the person setting up felt like putting into the machine that day. That said, books can tell us what hook was installed from the factory say at Durkopp Adler, Juki, Seiko, or the like. Ferdco or someone else could have installed whatever, and maybe have changed it up over the years with what they have or were sent who thought it was the correct one.- 16 replies

-

- bobbin case

- hook

-

(and 1 more)

Tagged with:

-

Chandler c-267 motor

Gregg From Keystone Sewing replied to Tazz63's topic in Leather Sewing Machines

Didn't see that Sailrite video, thanks for sharing. -

For short periods of time, Brother (and Singer) distributed the Seiko line in the United States. This is not a Seiko copy, this is a real deal Seiko machine,and I'm sure has many parts stamped and embossed Seiko logo. Specs on all series of this machine are the same, however "C" models are under bed trimmer machines, with auto presser foot lift and auto back tack. This factory longarm from Seiko was always very expensive, by any standard. Make sure the motor for the machine is not a 3 phase 220, many of them were at that time.

-

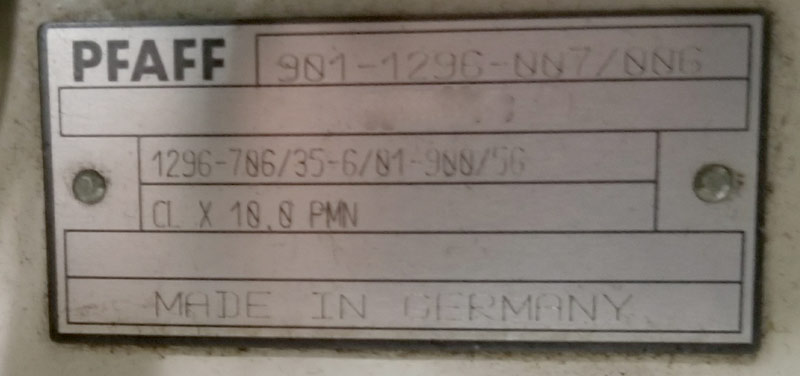

Pfaff stitch length adjustment post bed

Gregg From Keystone Sewing replied to Oakley's topic in Leather Sewing Machines

Here's some images from a machine we have laying around here, this is controlled by pneumatics, but the stitch length is regulated by the stitch length knob. Cover was removed so we can see working components. -

Pfaff stitch length adjustment post bed

Gregg From Keystone Sewing replied to Oakley's topic in Leather Sewing Machines

I was looking into this, and Pfaff seems to have at least two pneumatic back tack setups, and maybe more? What's the model tag on the back of the arm machine provide say? Best thing to do is take a picture of the brass plate, there may be a lot of numbers and letters, and post it here. This is an interesting machine. -

I couldn't resist......

Gregg From Keystone Sewing replied to Chayse's topic in Leather Sewing Machines

Nice looking machine, never seen a stand made up like that, but like it and see the utility in it. All parts are still available for the Singer 7-33 as well, and this machine is far from dead. -

207 Top thread, 138 in the bobbin. I'm sure you can find much more information on this message board for sure. The Juki LU-563 and Consew 255RB series are top loading, large bobbin, walking feet machines. They were made over a long period of time, and the quality is good. As said, the Consew 254RB is a needle feed only, where the LU-563 was only a walking foot series.

-

Consew 255RB series is true walking foot; top presser foot, bottom feeder, needle feed, with alternating presser feet. The 254RB is the same, except that it is a needle feed only and feed dog only, and the top foot is fixed, on a hinge, and has constant pressure on the goods being sewn. Consew 254RB does not have alternating presser feet. This is not a problem, as long as the material can slide on the top foot if it is not rubberized or gummy. It has to be able to slip. Also, the needle feed will not climb over inconsistencys or heavy seams in the material like a true walking will. All of the spec. sheets on the Consew and Seiko explain this, but it can still be confusing, and hope this helps. It's a really good machine if it works for you. I also think that calling both a drop feed is not at all misleading, but maybe a bit confusing as well. Consew's website has downloads that are pretty clear about this, CLICK HERE

-

Need answers about my Consew 220

Gregg From Keystone Sewing replied to debarooni64's topic in Leather Sewing Machines

Uwe, I've never seen that darning foot, I want to check it out. This daring plate would work great, too. It would help prevent flagging, for sure. I can't tell from the video if they have this or the standard feed and plate, or just the standard plate without the feed maybe? I have no idea from the video.- 7 replies

-

- consew 220

- consew

-

(and 1 more)

Tagged with: