-

Posts

2,283 -

Joined

-

Last visited

About Ferg

- Birthday 01/21/1934

Profile Information

-

Gender

Male

-

Location

Southwestern Ohio

-

Interests

Anything I can do with my hands and mind

LW Info

-

Leatherwork Specialty

Everything that is unusual

-

Interested in learning about

everything

-

How did you find leatherworker.net?

Web

Recent Profile Visitors

35,650 profile views

Ferg's Achievements

Leatherworker.net Regular (4/4)

-

Are you still interested in knife. Some clarification of your intentions Please. Ferg

-

1/8" Plastic lace, 100+ yards $12.00 plus shipping 1/8" Calf Lacing, one spool has 50yds other one has 40yds This is top choice lacing, Dark Brown color. $50.00 plus shipping 1/8" Goat Lacing 18'. This is second only to Calf lacing in quality, medium brown color $5.00 plus shipping 3/32" Goat Lacing 20-25 yards Tan color $15 plus shipping Picture tells the story plus 90- 100 yards 1/8" wide light brown color $7.50 plus shipping Picture tells the story, plus 90-100 yards 1/8" wide dark brown color $7.50 plus shipping If you are interested in all the lace listed I will give a discount.

-

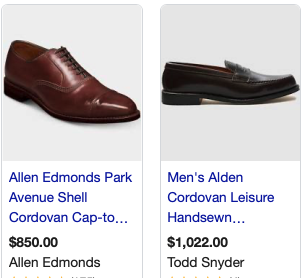

"BATTERIES NOT INCLUDED" I will part with these with a heavy heart, they are very hard to find at any price. I have three Natural Horse Butts. Measures 48" tip to tip. Fifteen inches wide at widest part. 8oz. 1.7sqft. Great for sheaths, holsters, bags straps, razor strops, welts and belts (when long enough). $160 ea. plus shipping This price is solid. ____________________________________________________ Horween Cordovan Shell Info concerning cordovan shell: One shell in entire hide of a horse which is taken from the rump. Exceptional leather. I called Horween some years ago to see if they had any in stock. After talking leather with the gentleman on the phone he said he would look for me to see if he could grab a couple from the line. I paid $245 each for the two. They sell for $345 each now if you can find one. I will sell this one for $245.00 plus shipping There is no wiggle room on the price. Thank you for looking! Shoes today !

-

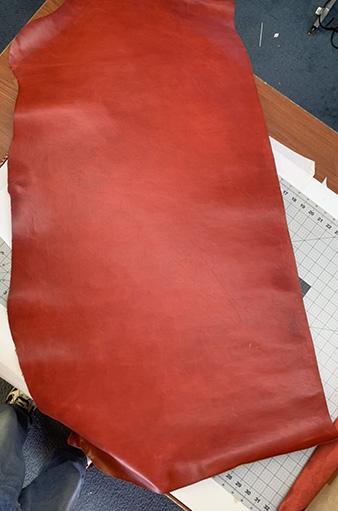

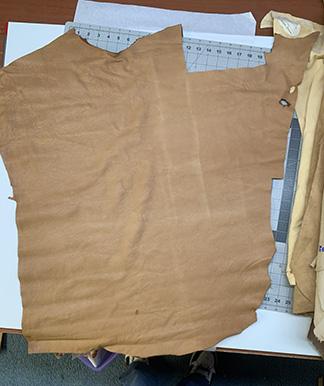

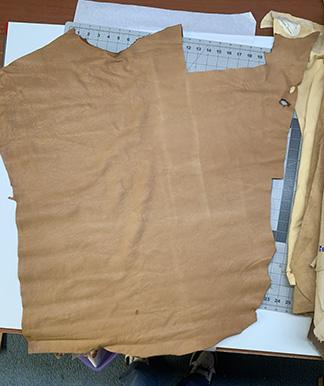

Lisaro Beautiful Chinese red color, 3-4 oz, 5.75 sq ft. I bought a number of these hides when available. I have several left. Have not seen them since. They were from Italy. $75 plus shipping Beautiful mahogany colored calf skin. .06mm thickness. Excellent for wallet linings and Credit Card slots. 5.75 sq ft. $75.00 plus shipping This is a large hide I couldn't get high enough to photograph entire piece. Calf skin, .8mm thick, 6 sq ft. Makes excellent wallets. Reddish cordovan color $130.00 plus shipping Soft Pigskin. 5.2 sq ft. .6mm thickness, Light Tan Gloves, boot tops. etc. $60.00 plus shipping

-

Dave, I have a lot of stuff to list yet. It is a real bear going through almost 70 years collection. Will contact you. What are you primarily interested in? Ferg

-

Left handed Shoemakers insole/channel knife made by Tina of Germany. Sells new for $219.00 I am selling new out of box for $175.00 plus shipping New TEKTON TOOLS Nipper/Tack puller Made in USA $20.00 plus shipping NEW - LASTING PLIERS $40.00 plus shipping NEW - BRASS SMOOTHING TOOL. Used for smoothing leather toe area of shoes and heel area. I paid good money for this tool. $25.00 plus shipping More later

-

Top photo is of an Osborne six inch round knife. I bought this when I was in the Navy Circa 1954. Number embossed in blade doesn't come up on Google. It has been ground professionally and cuts leather like butter. There is a slightly flat spot at the top of arch. I do not remember why that is there. $50 plus shipping Round knife at bottom of photo was custom made for me by Terry Knipshield. Three and a quarter inches tip to tip. This is a top of the line blade. I used it to skive leather and cut intricate pieces of leather. Blade is scary sharp. $200 -=SOLD=- plus shipping. I will not take less for this blade PayPal or Postal Money order

-

Buying A 227R What I Have To Check The Most?

Ferg replied to BodegaBrasil's topic in Leather Sewing Machines

Bob and Bobbie are not only great at their business, they are great individuals and will give you a good deal. As Wiz said, they have rooms full of everything -

I have eight more hides of this LAMBSKIN leather varying in size from about 6 sq ft to 7.5 sq ft. All same color and thickness. Anyone wish to have more than the three or if you wish to buy only two, I will give you a good deal. Just let me know.

-

4.5 sq ft x .8mm LAMBSKIN #3 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. I had taken some cuts from this hide $25.00 plus shipping We take PayPal

-

7.5 sq ft x .8mm LAMBSKIN #2 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. $50.00 plus shipping We take PayPal

-

6 sq ft x .8mm LAMBSKIN #1 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. $50.00 plus shipping We take PayPal

-