-

Posts

2,274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ferg

-

You have a fine hand, I will always admire excellent craftsmanship.

-

1942 Ford Sedan. Mom and dad were somewhere with that car at home with the keys in it of course. I was ten years old and just had to drive. Took it down to the barn, turned it around and back up in front of the house. I just had to drive it a little further so I could put it back just as it was. I don't remember they ever noticed anything out of the ordinary when they got home. When I got to the ripe old age of 14 I worked at a local feed mill for $5 per day. Owner had an old Chevy 3 ton flatbed with racks. We delivered coal and lots of feed to farms and others. He was short handed one day and ask me if I could drive the truck. You didn't really think I was going to say no! Piled feed sacks on the seat so I could see over the steering wheel. Never had an accident and drove it all over the township for two or three years!

-

I am forever fascinated by what computer driven machines can accomplish and I am fascinated by what hand crafters can accomplish that after seventy years of doing leather off and on I am "ordinary".

-

Straight Lacquer

Ferg replied to Tim Schroeder's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I have shot thousands of gallons of Lacquer, mostly "Satin". We used to buy as much as 50 five gallon cans, easier to poor and stays viable better, from SW. Was normally a month's supply. Sprayed on most everything imaginable but never used it on leather. Used a lot of Neat Lac on leather. Don't remember it ever cracking. Sure had a strong odor. lol Yes we sprayed from quart container spray guns. Used six different guns in spray booth equipped for three people spraying. -

-

Still fighting after affects of the stomach flu. Not much going on here for Christmas Cheer this year, everyone is sick..Going to build a big fire in the fireplace after while.

-

I don't post often anymore, slowing down a bit. Spent four days in hospital this past week. I enjoy reading most of the posts anyway to this day. AND!!!! I am glad I can wish everyone here A MERRY CHRISTMAS AND HAPPY AND PROSPEROUS NEW YEAR.

-

-

There are many options available today. You should look into a Diode Laser of something no lower wattage than 5 and10W would be a good starter. You can engrave wood, cast acrylic, leather, and a number of others. Fairly steep learning curve but if you are determined and keep plugging away at experimenting etc. you will be greatly rewarded. Totally fascinating. I have explained the size in above posts.

-

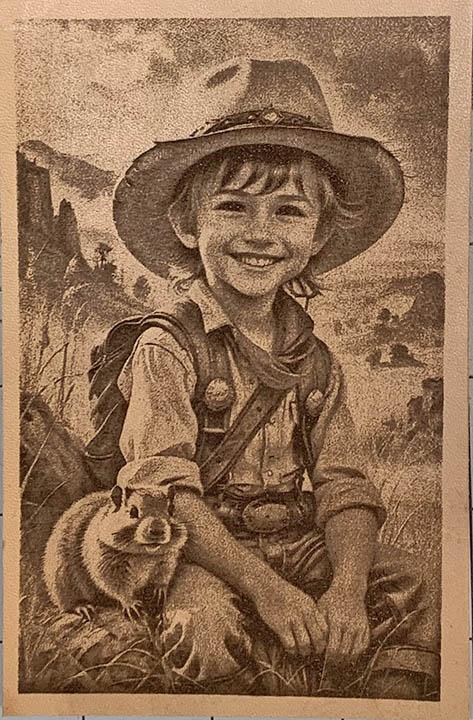

I use PhotoShop, Illustrator, and various other programs. And! Three years of experimenting. My laser is CO2 60W with LightBurn. Marmot or Prairie Dog

-

The laser actually burns the image into the leather. Different shades of Gray/Black gives you different amount of burning. Depth varies with power and speed of engrave. This one is engraved about .5mm in depth

-

-

Tried something new

Ferg replied to JDFred's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Cooking spray is "Oily"/greasy. I don't think it would qualify along with Neatsfoot oil. Any oily substance seems to have a tendency to rub off on clothing unless it is dried. Heck, I used vegetable oil to finish some wooden plaques we used to make. -

I have this set of curved awls for shoe stitching on sale for $75. I assure you I paid almost that much for each separate awl. They are made in USA.

-

Sorry for the senior moment folks. The smoothing Iron is $25.00 Prices are plus Shipping continental US.

-

Thanks. I will just make another post

-

Oh Crap! How do I Edit the post now? Just do a new post/reply?

-

These tools and the Sole Bend are of excellent quality and all are in like new condition. #1. - Sole Bend Leather - 26” x 60” X 5mm (slight quarter inch). Never been cut. $110.00 #2. - Shoe Fit Gauge Calculator. - $30.00 #3. - Lasting Pliers - $15.00. Nippers - $$8.00 #4. - Channel Cutter - $85.00. Channel Opener. - $40.00 #5. - Shoemaker’s Awl Set - $75.00 #6. - Smoothing Hammer I do not have a photo of the Sole Bend. Put it back in the box before I remembered to take a pic. Nice clean piece of leather good for sandle or shoe soles. #2. Shoe size calculator #3 Lasting Pliers & Nippers #4. Channel Cutter and Channel opener These are Barnsley and Bros. tools lightly used #5 Stitching Awl Set These tools are American Made. #6. Smoothing Hammer. Great tool for smoothing toe of shoes and most everywhere you need smoothing of the leather.

-

I agree 100% with your post. Ferg

-

I have owned recently, both cylinder arm and Post bed, both were Cowboy. While the Post bed was an interesting machine to use it wasn't intended for heavy sewing. Mine would work great with 92 thread it really didn't sew as easily with 138 although I did use it occasionally. Looking back the cylinder arm would be my suggestion. I done some shoe work also wasn't impressed with either machine for shoes.

-

Wiz, Every time I read one of your posts with all your machines listed I think of what my wife says about all the equipment I own and some I haven't used for so long. "Why don't you sell it?" For the most part no one wants to pay what you feel is fair, so it still rests in my shop and shed. Love to hear about the old machines. Had a good friend who was a shoe repairman. He had all those old machines and the entire shop smelled of lubrication oil and leather dye at the same time. He sold all of his shop before he died and I simply didn't have the $2500 or so to buy it.

-

I’m losing hope with my consew 206RB-5 and I need advice.

Ferg replied to Tsiatko's topic in Leather Sewing Machines

I have a Consew 206 RB5 made in Japan by Seiko. First industrial sewing machine I bought. I love the machine and use it for everything from wallet insides to medium heavy belts. Machine will not sew well with anything above 138 thread, I have used 40 and primarily use 69, 92, and 138. Needle size is extremely important. My machine came from a distributor who didn't set the machine up for leather. With an awful lot of help from Wiz on this forum I managed to get things adjusted and set to sew anything I wish even my dungaree cuffs. Do you have a manual? If you do not I can make a copy for you and send to your address if you pay the postage. It isn't a large manual and has a car load of info. Industrial machines have to be set up correctly if you wish to do anything with them. Anyone not motivated to get all the info available, I don't mean You Tube, has no business buying an industrial sewing machine. Just my 2Cents. -

My 2cents: Why don't you layout your design so you have enough design to do less than half the belt area you need for the design. Leaving several inches of space between the two designs in the "rear" portion. You don't need to be quite as fussy with alignment but it shouldn't be any big deal. Worth a try?

-

Are you interested in the drop downs I have?

-

Tie a slip knot at the loose end.