-

Posts

1,983 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Beaverslayer

-

Welcome Emily, glad to have you join the forum. That's a good looking collar you've made there. As to the Chicago Screws that the others have mentioned, here's what they look like. Ken

-

a new inside layout

Beaverslayer replied to corter's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Corter your wallets just keep getting better each time. As Grumpy said, you can by thick clear plastic, I've gotten it from the fabric store as well. Love the design. Ken -

cleaning glue brushes: white glue and contact cement

Beaverslayer replied to esantoro's topic in Hardware and Accessories

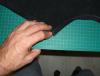

I'm not sure if this works with Barges or the smelly contact cement, but it woks real good for the water based contact. When you get a big blob of glue stuck to your brush, and it's not working as well as you'd like. Do this while the blob is still somewhat wet. Take a piece of scrap pigskin and fold it over the end of the brush. Squeeze tightly, and pull the brush away from the pigskin. You may have to do this 2 times. Here's how clean it came after 2 pulls. -

If you've done a weave or extra something on the back, or anywhere else that you decide, and this weave goes to the outer edge, you will have to be careful when punching the edge trim holes when you reach this point. The thing to do, is once you've marked your holes along the trim, punch up to the area that has the weave on it then stop punching. Flip the vest over, so that you can measure and mark, then punch the holes from the outside. This will prevent you from punching through the weave lace and making a big boo boo. Once it's laced up along the outer edge, you can see how the 2 laces kind od merge together.

-

When it comes to marking the nylon mesh to glue the edge trim down, I find the easiest thing to do, seeing as the nylon does not like the gel marker. Hold the edge trim down, and with small pieces of painters tape, slide them just under the edge and press down. Once you've taped off the whole edge, then you will have a marked off area to glue. Also, with this water based glue, it tends to tack up very fast on the suede and the leather, this is not the same on the nylon. Once you've applied the glue to the nylon, you will have to leave it for about 10 minutes before it is ready to attach the edge trim. Make sure you roll these seams REAL good.

-

When it comes time to mark the other side grommets, what you want to do is to line up the curved corners, that's the top of each side under the arm. Then with your gel pen, mark the centre grommet from the side that's already done. This will give you the location of the centre grommet, and now you can measure 1 1/2" between each to locate the rest.

-

When lacing the front of the vest, you want to lace in 2 directions, working towards the bottom point of the front as shown in this picture. This will give you the same lace design on both sides of the front panels. Rather than lacing all one direction, and having the lace going a diferent directiom as it runs back up the front. When you reach the bottom point, you want to got one stitch past so the joint in the suede edging is secured. This is the completed front panel. On the back of the vest, you also want to lace from 2 directions, starting where the back meets the shoulder piece and working down and across to the middle of the back. Measure the middle of the bottom of the vest, and this is where you will stop your lacing in each direction. I know the holes are not punched in this picture, but i wanted to be sure I remembered to talk about this.

-

Randall Pouch for a Randall

Beaverslayer replied to Grunt's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Real nice looking there Grunt, a nice set indeed. Ken -

Welcome Kevin, good to have you here. I hope you can find what you are looking for in regards to making boots, noy sure who is here that knows how, but I do think there is someone. Ken

-

Ariel, welcome to the forum. You are going to find that this place is just full of helpful people and lots of knowledge. Some of the best leatherworkers in the world are here to help out as they can. Enjoy. Ken

-

Real cool Frog, I think you should take up saddle making now and do a saddle like that. I also like the idea of kind of hiding the skulls in the work a bit more, kind of like that artist that hides the horses and such in her paintings. Ken

-

Very interesting way of shading and blending Scouter, it came out very nice. Ken

-

Great looking cover Tom, adds some real character to the book. Ken

-

WOW....no I mean WOW That is just AWESOME. I'm in awe of the Dragon mask, and that Monarch Butterfly, is to die for. Great masks, thanks for sharing. Ken

-

Glue for leather

Beaverslayer replied to MarkS's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

After a trip to Home Depot, I've found another brand of the same glue as the 3M. It is Lepage Pres-Tie Green Water Based Contact Cement. I've tried it and it works just as good as the 3M. It's actually the glue I'm using in the Custom Vest Tutorial. Ken -

That's some fine scroll work there david, very nice looking. I really like that lace as well, will have to give it a try also. Is this one going to be dyed or left natural? Ken

-

Real nice looking Spider, I love what you come up with. When you do this type of lacing, you want to use a slotted hole, not a round one. Punch the slots on an angle and the lacing will come out real nice. I remeber Marlon posted pictures of just how to line up and punch the slotted holes for this type of lace, can't remember just what section though. Ken

-

Intro + a holster

Beaverslayer replied to Shorts's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Welcome to the forum short, good to have you here. So far the holster looks good, can't wait to see the end product. You've come to the right place to get any help that you may need, ask away and lots of people will help out with answers. Ken -

Very nicely done laethercat, the coloring of the flower is very good. You got the shading just right. Thanks for sharing with us and keep up the great work. Ken

-

Start your lacing where the yolk is attached to the front panel. Use a piece of lace NO LONGER than your arms length. The reason for this is twofold. 1: It is way easier to work with short pieces of lace, rather than 10 or 12 feet of it. 2: As you lace, the lace will wear away, as you'll notice from all the leather dust on the floor. We do not want the lace so long, that it starts to get thinner as we go along. This will make your lacing look real bad where you splice it, as one will be thinner than the new one. Run your needle under about 3 laces back, and out between the first and second lace loop on the bottom of this seam. Then run it into the second hole on the inner side of the seam, pull the lace through and snug. On the back, go back to the first hole and run your lace through, and lace away as you have done before. These stitches you can pull a bit snugger, and also be sure to give them a bit of a twist where they come out of each hole to make them nice and straight. If your getting close to the corner, make your splice before you go around it. Always make your last stitch to the inside hole and back to the front before doing a splice. Sand off a small area between the two rows.Then cut your lace off as long as the sanded area. Glue and roll this tail down. Now from about 3 stitches back, run your needle underneath and out he end of the seam on the outer edge of the glued down tail. Run your needle into the first outer hole, and continue on lacing. This picture shows you the reason why we made thos holes close to the mitred corners. As the backside stitch is put in place, these will hold the mitred corners from coming apart. This is what the outer lace should look like...quite a nice look I think. And here we have the inner lace look. Again, this is a real nice looking finish to the inside of the vest. Now you can continue on lacing, as I will be, and as soon as I'm finished I'll post the finished work. There is a few more lessons to come, but that won't be for a few hours anyways. Thanks again for all that have left comments and compliments, they are much appreciated.

-

Where the vest fron meets the yolk, you will have to punch two holes just under the lace that holds the yolk to the vest. You can see in this picture what I mean by this. Now, flip the vest over, and working from the inside, you can start your marks from these two holes. Again work from both ends and make any correction in the middle. Here's what the holes should look like.

-

On the outer edge of this, your first hole is NOT 3/8" away from the mitre hole. As shown, it is inline with the first hole on the inner side. This is to keep the lace seam straight from the corner on down. This is what the holes should look like when punched. The corners will all look the same as this.

-

Now we are ready to start punching a million holes. You want to punch these two holes first. These holes are placed as close to the mitre corner as possible, allowing enough space on the inner edge not to beak the mitre. From there you can start to mark your holes 3/8" apart. Do the same thing on all the corners as you've just done on the last one. What I do is work from both directions, and if the last 2 holes are not 3/8" apart, I will correct this in the middle of the run.

-

Once I have this section of the vest done, I like to place the grommets, this will help to hold everything here in place when we are pulling and turning the vest when we lace it. Find and mark the centre of the gusset and make a mark. From this mark, measure up 1 1/2" and place another mark, then 1 1/2" again. Do the same in the other direction. This will give you 5 locations evenly spaced apart. Now using a grommet, place it centred with each hole and mark the circular centre. Punch these holes and insert and assemble the grommets. Always put the grommet ring on the inside of the vest, as this gives the outer side the finished grommet.

-

Long day...I forgot to show you something... To get the right mitre on the corners, fold one over the other and from where the two meet on the inside, make a mark to the outer point of the corner. Cut this bit off. Then fold the two down again and use the cut edge as a guide to make the second mark. Cut this bit off as well. This will give you the proper mitre. I know it looks like hell now, but once it's in place, it looks real good. Now, using a sharp knife, cut the edge trim away from the edge of the gusset as shown here. Be very carful to just cut deep enough to cut the suede. Then sand this marked off area around the edges. Apply a bead of glue to the entire are that is shown here in this picture. Let this get tacky, then fold the edge over and press and roll together. Be sure to get the fold nice and straigth. After folding the edge over, marking and measureing the distance from the outer edge (yes do this each time to be sure, in most cases it will always be the same as the first measurement, but let's just be sure) continue on with the rest of the outer edge. Notice the mitred corner doesn't look bad at all. Here's waht the edge should look like from the outer side of the vest.