-

Posts

208 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gigi

-

I also prefer the Giardini 'Maxmatt' Semi-Dense Edge Paint and an Extra Matte Topcoat, colorless. The dense edge paint can be thinned with a bit of water. I've found info about edge dyeing process using Giardini products on their website: http://www.leatheredgepaint.com/

-

Thank you!

- 14 replies

-

- wrinkled leather

- creased leather

-

(and 2 more)

Tagged with:

-

Another product is 'AMACO Rub 'n Buff Wax Metallic Finish', finished with a clear coat (otherwise it does rub off constantly). 'Angelus' acrylic leather paint has also metallic look but comes in bronze, not brass: https://angelusdirect.com/products/bronze-paint

-

Thank you for the photos, Brian! Found also this video:

-

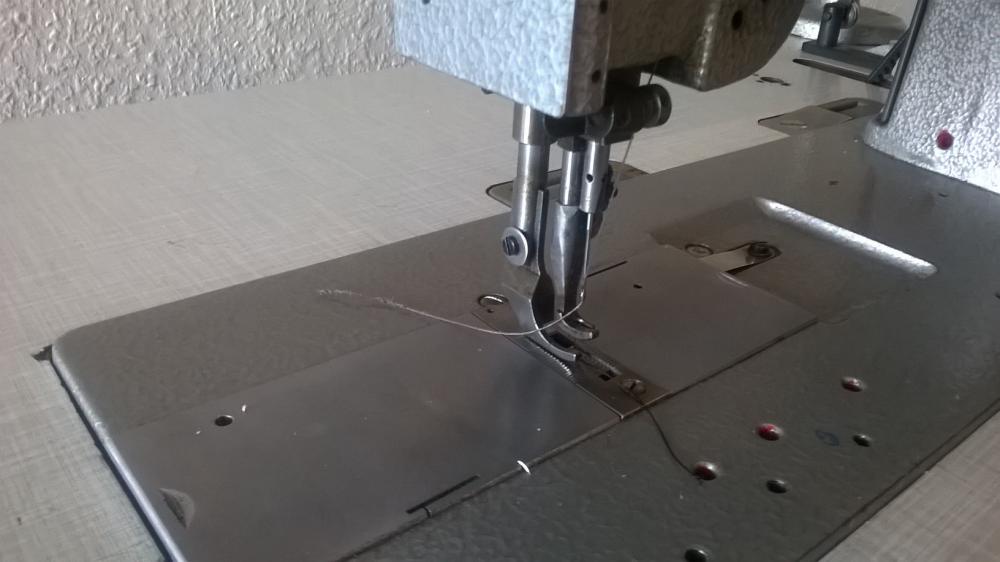

I also want to find out. I've seen those sewing machine zipper feet I want to order: https://www.ebay.com/itm/TOPSTITCH-FOOT-SET-1-8-3-16-1-4-EDGE-GUIDE-FEET-S585-3-/292096855600?hash=item4402544e30 Seamstick Double-Sided Basting Tape is, of course, very useful in attaching parts together.

-

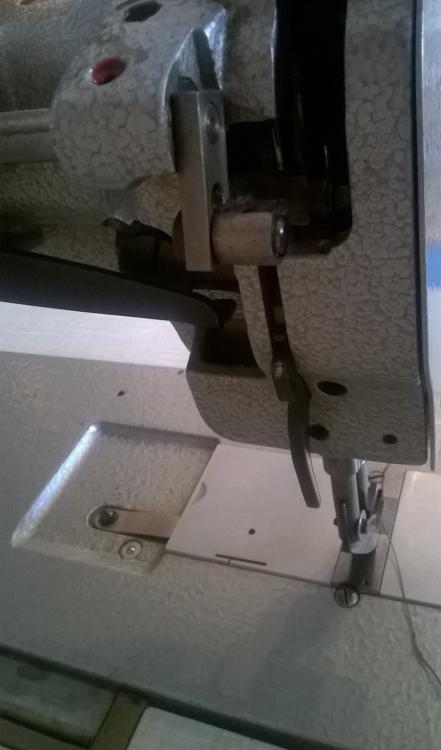

This link is to a seller catalog, there are many models of V1000, seems you should ask about: 'VZAB0P4BAA'. I also have a V1000 (see the one in the photo) that transforms one phase 220V electricity into three phase’s 220V electricity. Mine was bought used for about 50 Euros. Brand new could be expensive. If you go with VFD solution I recommend to have someone authorized doing the wiring.

-

Don't feel like that: my husband needed very long time to learn this because of his hobby. If you don't feel comfortable with this solution, you can always use an out-of-the box solution: a servo motor. I prefer the VFD because we think the 3 phase motor has better torque at low speed. Looks like the one from your last link would work for your application, even though I prefer a well-known brand name for this. Found this one for example on eBay Germany: https://www.ebay.de/itm/Omron-VS-mini-J7-CIMR-J7AZB0P7-1-1kW-0-400Hz-230V-Frequenzumrichter-Inverter/221976850054

-

I don't think I would use this one: I cannot see the output ('3 Phase') and also variable voltage and frequency so I would not buy it.. Usually, on the VFD should be precisely written the input and output number of phases and voltage. Output voltage should vary from zero to maximum (240V in our case) and a variable frequency from zero to maximum value (in my case in the picture attached is 400 Hz). The one you linked has way too much power for your application i.m.o. On your motor nameplate I can see 220 Volts 1,7 Amps so this would be necessary for the nominal power. I think in your case a 0,75 kW VFD would be enough (like in my case also). I've bought a Japanese Yaskawa VFD from eBay.de in used (like new) condition.

-

@VinculusThe way I see the things is: with a capacitor you are using just one phase instead of three, so you have roughly 1/3 of the power coming to the motor. Using a variable frequency drive even with an old clutch motor works perfect for me. I have that installed for years on a leather sewing machine (sewing at low speed most of the time) and never had any over-heating issues. But if you are not a trained electrician you can ask one for help.

-

Thank you so much for the answers! I had no idea how those are made, I just thought it's a slow acting glue, to give time for shaping. I am going to try with different types of leather and post the results here.

- 14 replies

-

- wrinkled leather

- creased leather

-

(and 2 more)

Tagged with:

-

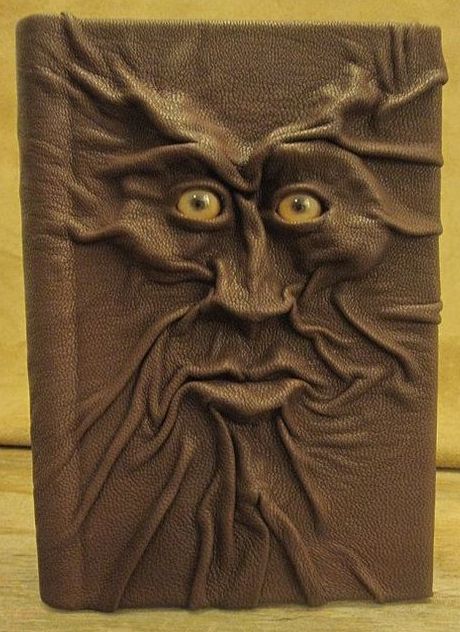

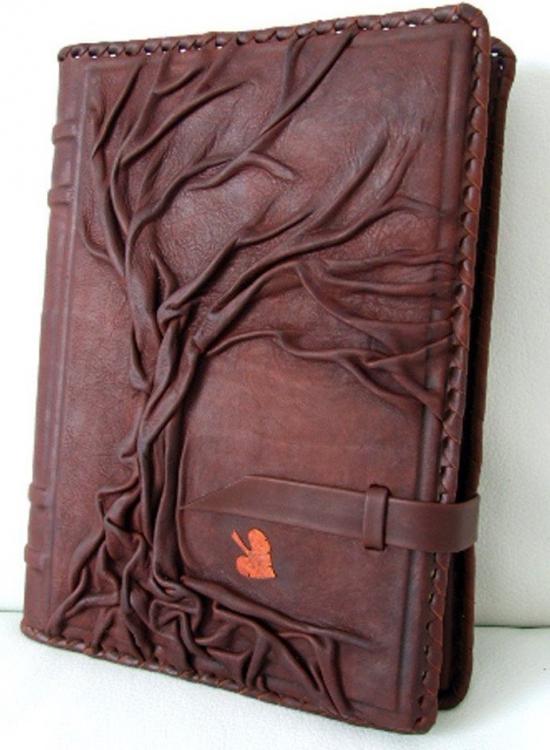

I was wondering what are the materials and what is the technique used to make something like this. Any ideas? (the example photos are from Pinterest) Thank you!

- 14 replies

-

- wrinkled leather

- creased leather

-

(and 2 more)

Tagged with:

-

'Double pouch bag/purse' or 'Accordion double clutch purse' or 'Fold over double zip purse' @RockyAussie Briaaan!

-

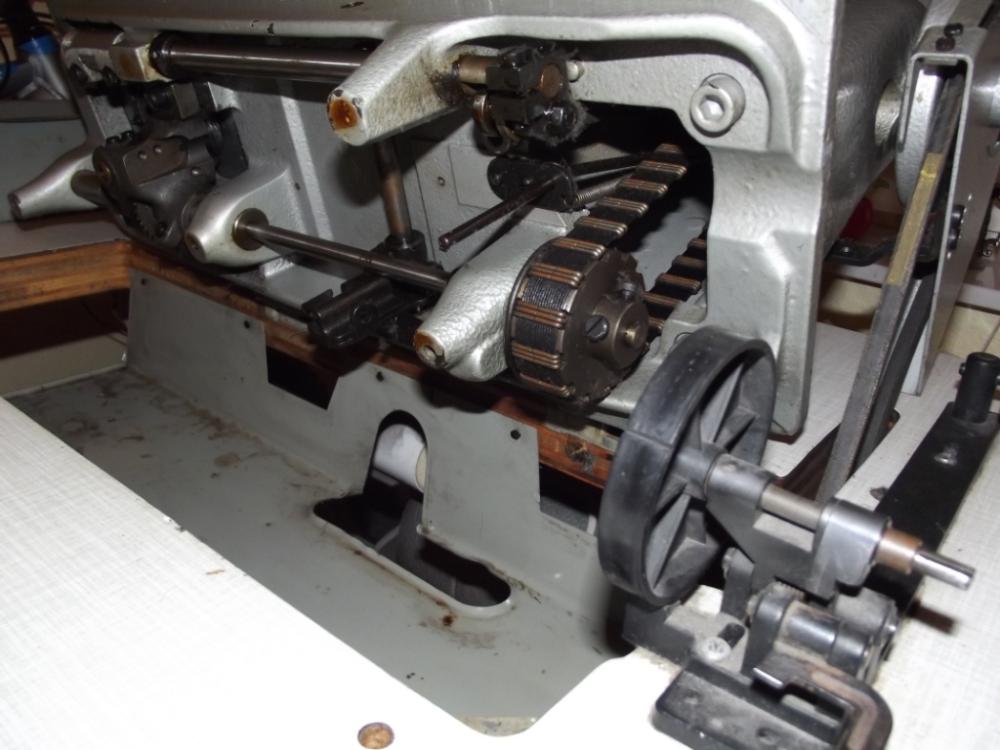

For sale is my Durkopp 239-525 (head only) in used but very good condition, well maintained, everything is running smooth. This is a medium duty, walking foot machine comparable with Adler 167 or Pfaff 545 and it is ideal for leather upholstery, canvas, leather clothing, even leather bags, belts, wallets etc. I mostly worked with NM120 size needle, Tkt30 (Tex 105) polyester thread. The machine takes 25 mm bobbins (outside diameter). For this machine you can use SINGER presser feet that are very inexpensive to purchase, available aftermarket, which also fit the Singer 111W or 211G, many JUKI or CONSEW machines with triple transport. Included in the sale: 9 bobbins, 2 spools of thread, about 20 needles (system 134-35 LR), one extra foot set, the knee lift lever, the belt guard. Machine was bought from Germany 1 year ago. Operating instructions available for download here: https://www.duerkopp-adler.com/export/sites/duerkoppadler/commons/download/public/249/B_238_239_245_249_372_380_541_DE_EN.pdf A video with the machine: Asking price: 375 Euro. If selling to Netherlands, Germany or Belgium: I can drive in 100 km range to meet the buyer.

-

Anyone with experience with Renias solvent based glues.

gigi replied to Danne's topic in Leatherwork Conversation

No, but I've tried BISON KIT 250ml: contact adhesive, universal, super strong; the one that specifies also 'leather' at 'Applications'. Is available at Hornbach stores. Thank you: I will test this one also. -

Anyone with experience with Renias solvent based glues.

gigi replied to Danne's topic in Leatherwork Conversation

Very nice card case! I've used Renia Top Fit and seems to me a very good/versatile glue. I haven't tried this one yet: Renia rubber adhesive (Renia Gummilösung "Extra") https://www.rickert-werkzeug.de/search?sSearch=renia -

I didn't watch that video, but I think he might glue something on this edge (a rolled edge, maybe) and this helps to glue it better (sticks together better than the grain side of leather).

-

LW user @gmace99 has useful videos regarding sharpening. For example this one, at the minute 1:12. I think the key for a longer lasting edge is stropping and polishing using a mix like in this video. You can also use a ready-made 'sharpening paste' ('honing compound') and a wool felt sharpening and polishing wheel (motorized). Making a device to keep the sharpening angle constant might also help.

- 37 replies

-

- sharpening

- japanese knives

-

(and 1 more)

Tagged with:

-

I think you will get more answers if you post the question under 'Fabrication' / 'Leather Sewing Machines' section of the Forum. maybe a moderator can move it...

- 2 replies

-

- binder attachment

- folder

-

(and 1 more)

Tagged with:

-

Thank you for sharing the tutorial and pattern!

-

Excellent looking bags! You're welcome! Hope Brian (RockyAussie) will step in and help some more.

-

Hi Sonya, We are not in the US anymore. I am not very experienced with the skiver, only recently acquired a used one (very old model) and now is working fine. With mine I've noticed: almost more important than the adjustments is the sharpening. My husband is sharpening the knife very well and checking the result with a magnifier glass. We've learned about the sharpening from @RockyAussie: "After sharpening very well and deburring you can use a leather that skives nicely and very slowly feed it through. This is a bit like stropping and helps to take away the fine rough edge. This also makes the edge last longer"

-

Awesome work!! What stamp are you using for the scales?

-

You're welcome! I hope it will work out fine Other ideas: Using a roller foot instead of a standard one. Check the stone: for very soft leathers should be fine grit (and not very coarse). Check the adjustments once again (according to the leather thickness). Feed wheel tension should be softer for softer leather. Feed wheel should be set parallel to the knife. One more video (very useful):