-

Posts

1,442 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mlapaglia

-

Leathercrafttools.com Pricking Irons / Diamond Hole Punches Question...

mlapaglia replied to TXAG's topic in Leather Tools

Ummm who is "them"? I cant find a link or name. OK its in the title. Never liked when the information is not repeated in the body of the text. dont mind me Im grumpy tonight. The "pitch" represents the distance between each prong tip. For example, as for 3mm-pitch tool, the every prong tip is 3mm apart from each other. Please keep in mind that the pitch has relevance to the prong size too. The greater numbered pitch tool has the somewhat thicker prongs. prong thickness is 1.5mm thick on a 4 prong. the rest is math to convert to SPI -

Flour and water is one way to make a paste. An egg white helps it too.

- 3 replies

-

- leather glue

- how to make glue

-

(and 1 more)

Tagged with:

-

Tiger thread Well I was wrong its from the UK but it will ship here. Whats the big deal about tiger thread? I normally use linen. Never used polyester for hand sewing.

-

Id suggest getting 0,1,2 size harness needles depending on what you are sewing 00 and 000 are pretty big

-

If you dont own a caliper you should get one. Since mine is just for leather I have a digital that measures in fractions, mm and decimal inches. Makes sizing leather easy. for $20.00 this one is fine for leather.

-

Call your local Tandy and see if they will replace it for you. It shouldn't do that (as I'm sure you know).

-

Thanks for the offer.

-

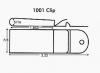

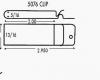

I just finished a belt for a customer that is 1-3/4" wide and 1/4" thick. None of my spring steel holster clips will fit the belt. Even the one that says its internal opening is 1.8" is just short of clipping. Any suggestions on where I can get a belt clip that rivets on and has a 2" internal opening and is at least 5/16" wide at the internal top of the clip? No J clip suggestions please. The customer wants steel clip like he is used to. This is what I'd like. The ones I have are 3/8" I need 5/16" at the top of the opening and needs to be 2" internal length. This might work if I could find it and not have to buy 1000. l Thanks Michae

-

Antiquing And Burnishing Question

mlapaglia replied to jpless77's topic in Floral and Sheridan Carving

Antique, burnish the edges and then finish with a LAC coat. Just give your edges a quick touch of sand paper before you burnish to make sure you have no resist on the edges -

Need Help With Sheath Idea

mlapaglia replied to Shooter McGavin's topic in Gun Holsters, Rifle Slings and Knife Sheathes

for retention mold a bump where the grip narrows so you have to pull it past that point to release the knife. Kind of like the retention on a trigger guard. It means the hilt would be in the sheath but it would work. Just an idea. -

Saddle Stitch Vs. Regular Stitch? And Sewing Tack ?s

mlapaglia replied to Cowgirlup8807's topic in Sewing Leather

A saddle stitch or hand stitch, is done by hand with two needles, one on end of a length of thread. Normal or Lock stitch is what is done by machine. While a saddle stitch is considered by many to be the best and strongest there is nothing wrong with a lock stitch. All your clothing is made with that stitch. There may be a machine out there that does saddle stitch but I am not aware of it. -

A 'stretchy' Leather For Straps

mlapaglia replied to citrusvanilla's topic in Leatherwork Conversation

if your leather is cracking its bad leather. Good leather doesnt crack when bent. As for stretch, any leather that stretches will keep stretching and make the fit loose. Suggest you set predetermined holes on the strap and the user can select the one that is closest to the fit they need at the time. -

Can you be a little more clear? What type of needles, Hand sewing or Machine? What size?

-

Do you guys have an FFL to receive a gun shipped to you?

-

Beer Holster

mlapaglia replied to Lala133's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

looks good, suggestion. Get a 1/2" stamp set for the letters. -

Look pretty good. +1 on the logo trademark violation. Hopefully you got permission. Is this finished or are you planing on burnishing the edges. That really pulls the holster together. Gives it a real professional look. Ya did good.

-

When To Change Needle In A Boss?

mlapaglia replied to mlapaglia's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Dwight, Shooter, I normally dont have 3 layers of 8/9 either but it was a welt in a special situation. I tried the finger test. It still felt sharp so I didnt change it. Michael -

I know this is the wrong forum but I need a quick answer if possible. I am using a Boss with 277 nylon thread and 794-200-S needles. I mostly do belts and holsters. How often should I change the needle. Is there a way to tell when it gets dull? Should I be looking for a change on how it comes out on the back side. Its not easy going through 3 layers of 8/9 so Im not sure I could tell if it gets a little harder pushing the needle through. (and yes I know if it breaks change it.) Thanks Michael

-

I know this is the wrong forum but I need a quick answer if possible. I am using a Boss with 277 nylon thread and 794-200-S needles. I mostly do belts and holsters. How often should I change the needle. Is there a way to tell when it gets dull? Should I be looking for a change on how it comes out on the back side. Its not easy going through 3 layers of 8/9 so Im not sure I could tell if it gets a little harder pushing the needle through. (and yes I know if it breaks change it.) Thanks Michael

-

Temporary Gluing Leather For Stitching

mlapaglia replied to superpacker's topic in How Do I Do That?

DAP Weldwood also works great. Home Depot has it cheap. with any contact cement be careful. once you put the sides together its stuck and almost impossible to move or realign. -

When Vinegeroon is finishing "brewing" it turns the leather black instantly. 24 hours isnt long enough for a complete batch. Plus after 3-6 weeks when it cant disolove anymore steel the ph is closer to normal so it needs less baking soda to fix it.

-

I am using a Boss with 277 nylon thread and 794-200-S needles. I mostly do belts and holsters. How often should I change the needle. Is there a way to tell when it gets dull? Should I be looking for a change on how it comes out on the back side. Its not easy going through 3 layers of 8/9 so Im not sure I could tell if it gets a little harder pushing the needle through. (and yes I know if it breaks change it.) Thanks Michael

-

If they buy everyone they hire the same basic tools, Edgers, gouges, Needles, etc then all the product will look closer to the same. If one person uses a keen edger #3 and and another person uses a regular Tandy edger #3 the edges wont look the same. While the choice of where to get the tools is poor the concept of everyone working with the same tools makes sense.

-

A poundo pad. they work well.